Methods and devices for improving efficiency of wind turbines in low wind speed sites

a wind turbine and low wind speed technology, applied in the direction of electric generator control, machines/engines, mechanical equipment, etc., can solve the problems of unsafe operation at high wind speed, insufficient conventional methods of generating electricity, and insufficient low wind speed operation to meet the ever-growing need for electric power, etc., to achieve optimum aerodynamic efficiency, simple and economical, and controllable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. Preferred Embodiments of the Invention Drawings

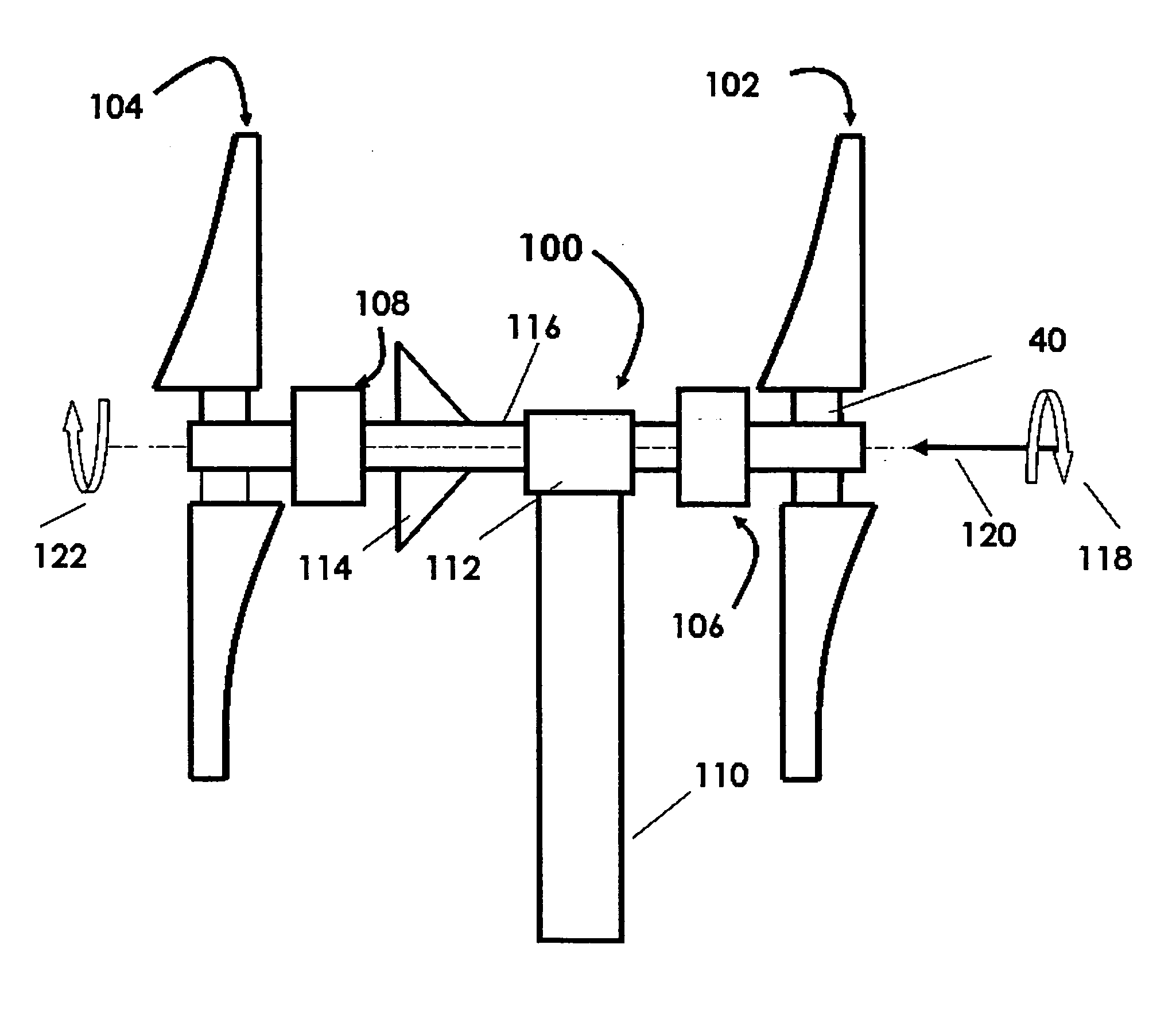

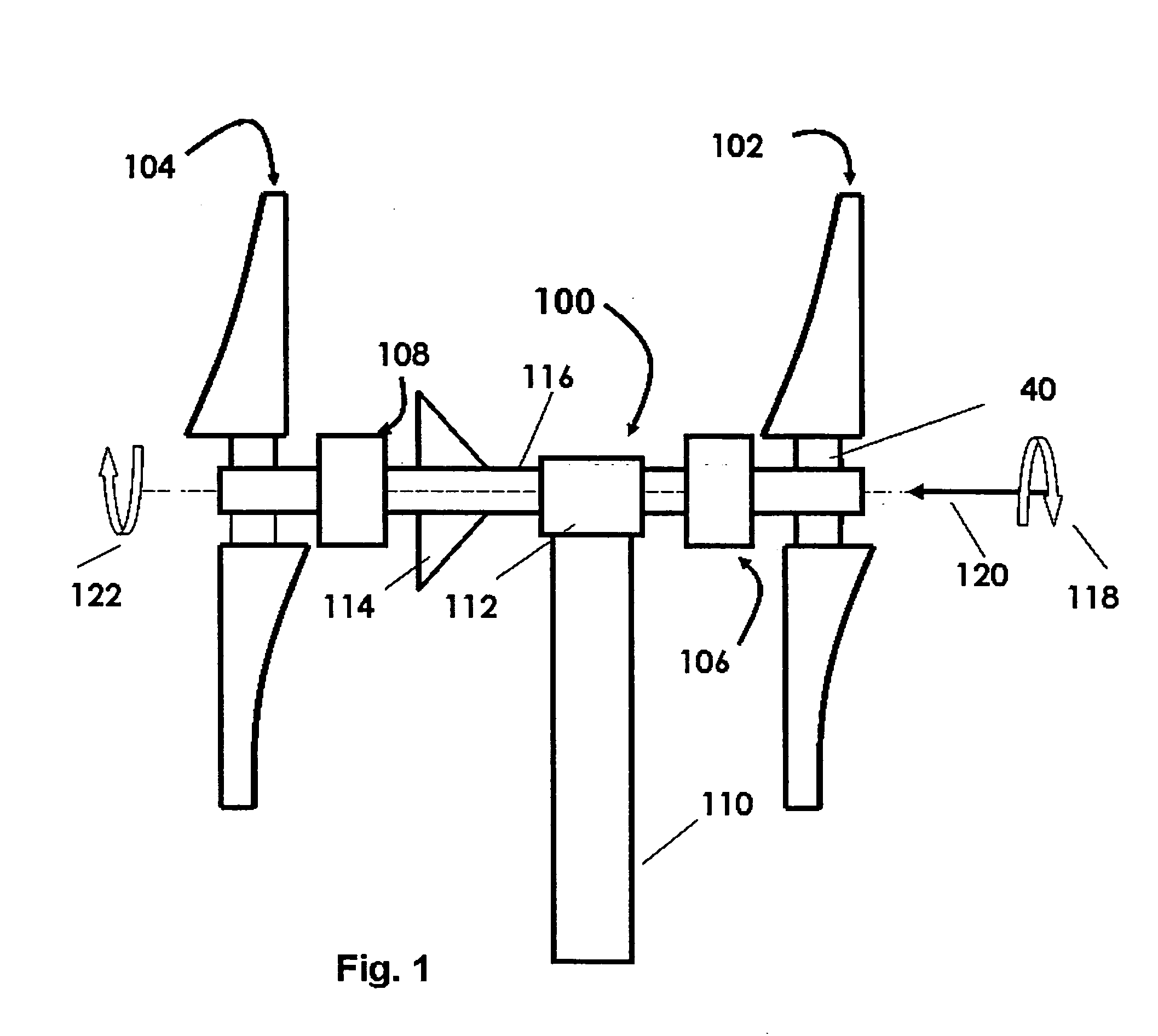

[0045]FIG. 1 shows a perspective view of a passively pitchable control device 100 incorporating the features of the present invention. Although the present invention will be described with reference to a single embodiment shown in the drawings, it should be understood that the present invention can be embodied in many alternate forms of embodiments. In addition, any suitable size, shape or type of elements or materials could be used. In FIG. 1, the passive pitch control device 100 is seen to include a camshaft 101 having half sine wave like groove (as depicted in FIG. 4), a cylindrical shell 13 supporting a blade assembly 102 and an axial compression spring 15.

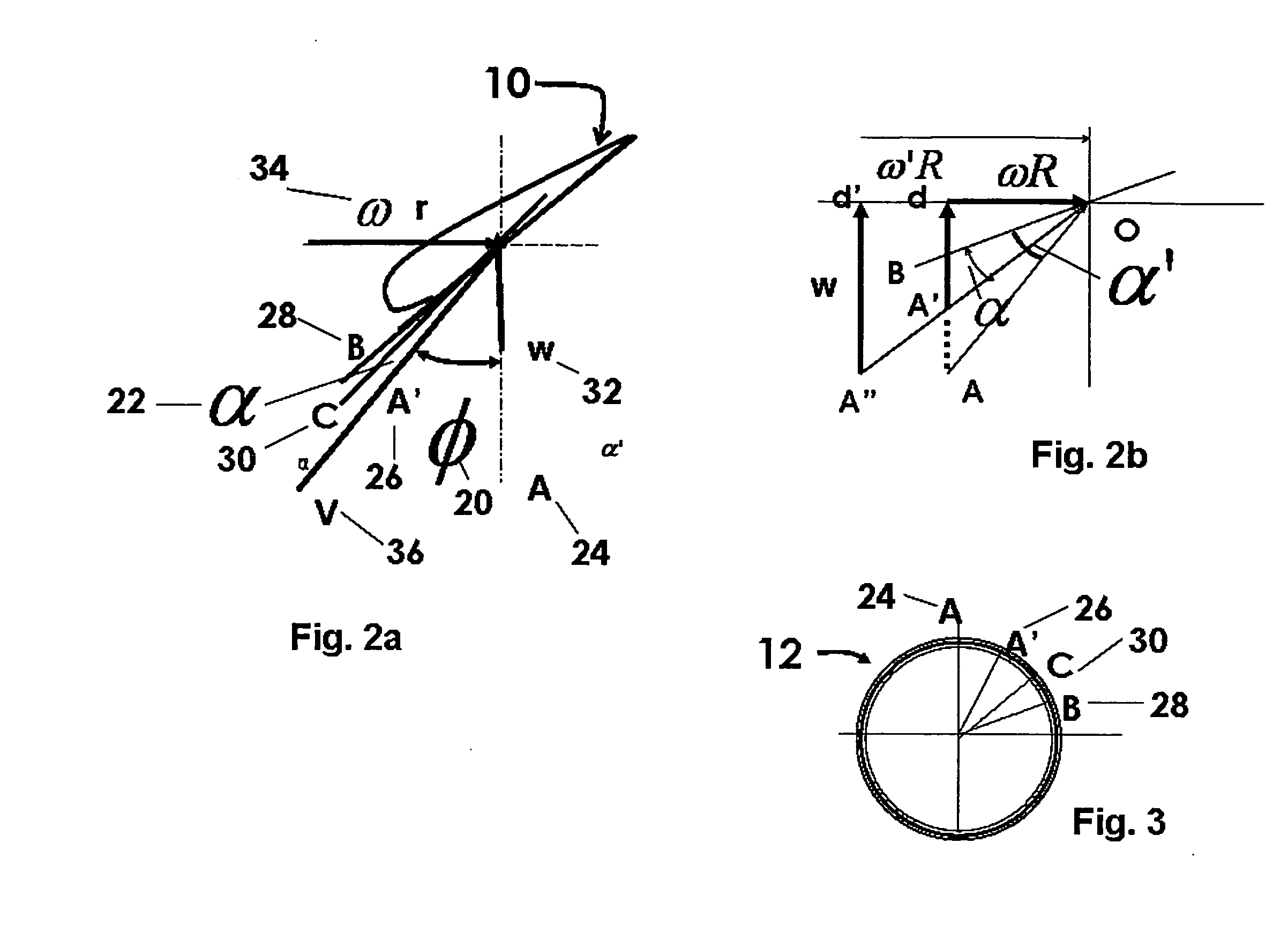

[0046] A cross sectional view of the camshaft 101 is shown in FIG. 3, while a 3-D rendering is shown in FIG. 4. Two sliding surfaces 22a, 22b are provided to support the shell 13 and the blade assembly 102. The blade assembly and the shell are fastened together by means of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com