Method For Treating Surface Of Material, Surface-Treated Material, Medical Material, And Medical Instrument

a technology for treating surface and material, applied in the field of treating surface of material, surface-treated material, medical material, medical material, etc., can solve problems such as degrading material itself, and achieve excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0072] Hereinafter, the present invention is described in more detail along with an example but is not limited to this example in any respect.

[0073]—Coating with DLC Film—

[0074] Coating of a DLC film over the base material is first described. In this example, an aluminum alloy (equivalent to JIS-8021 alloy) having a length of 50 mm, a width of 5 mm, and a thickness of 55 μm and polyethylene terephthalate (PET) were used for the base material.

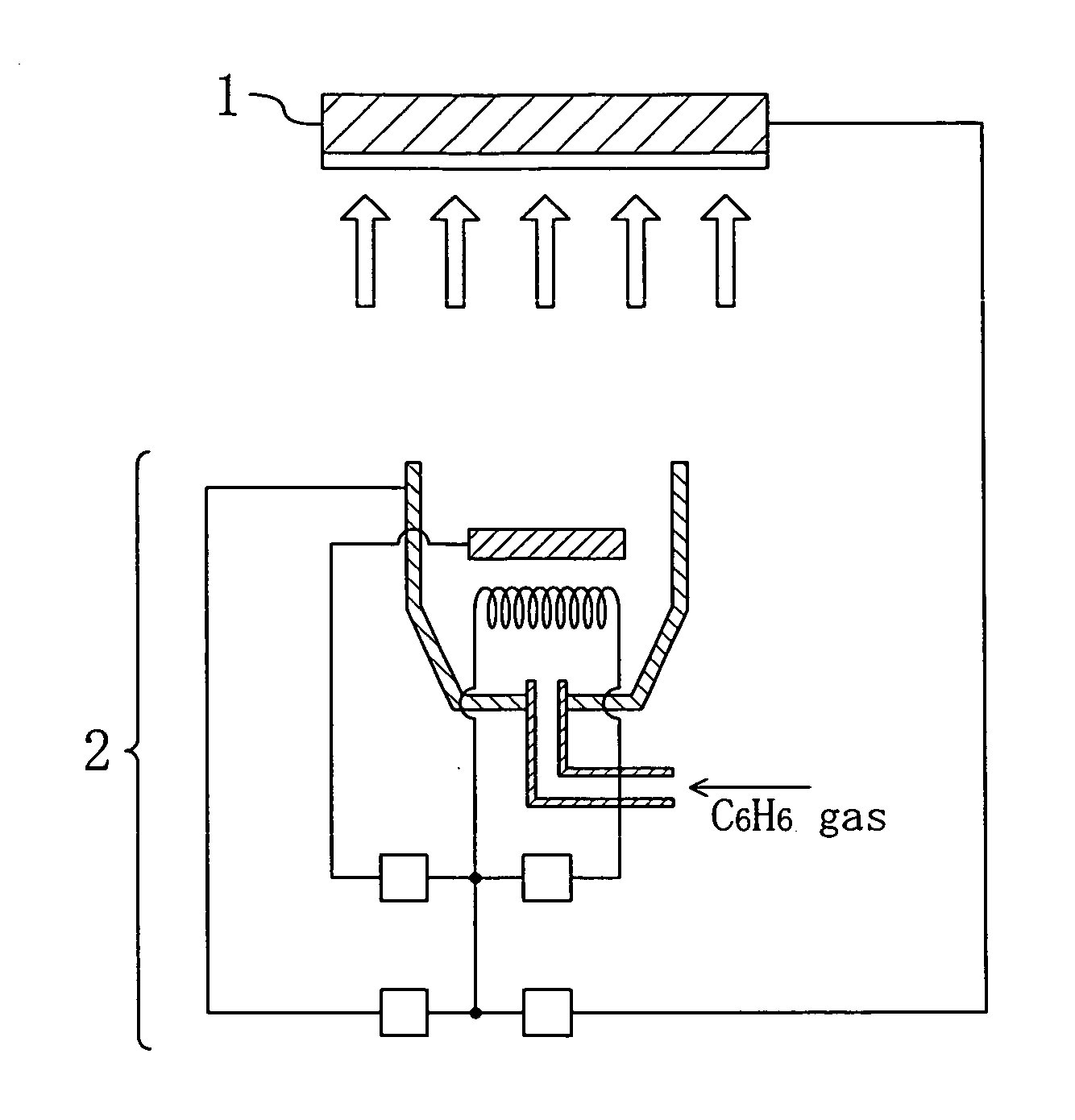

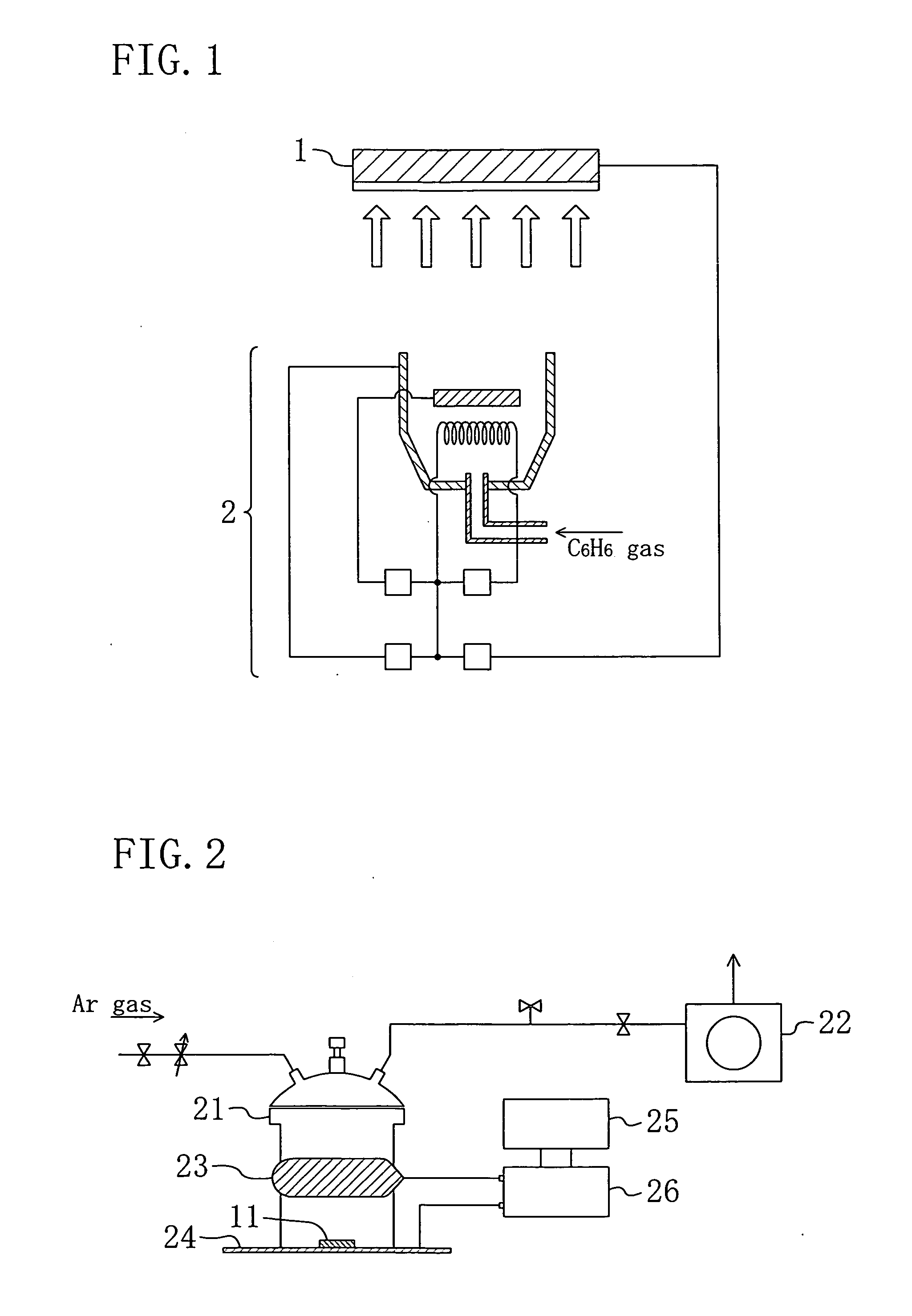

[0075]FIG. 1 is a schematic view of an ionic vapor deposition apparatus used in this example. The ionic vapor deposition apparatus is a commonly-employed ionic vapor deposition apparatus wherein benzene (C6H6) gas is introduced as a carbon source into a DC arc discharge plasma generator 2 provided inside a vacuum chamber to generate plasma, and the generated plasma is collided with a substrate 1 biased to a negative voltage, which is a subject of the coating, whereby the plasma is solidified over the substrate 1 to form a film.

[0076] The base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com