Reactors, systems, and methods for electroplating microfeature workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]FIGS. 1-9 illustrate several embodiments of reactors, methods, and systems for electrochemically processing seed layers, plating directly onto barrier layers, and depositing materials in other applications. Several specific details of the invention are set forth in the following description and in FIGS. 1-9 to provide a thorough understanding of certain embodiments of the invention. One skilled in the art, however, will understand that the present invention may have additional embodiments, or that other embodiments of the invention may be practiced without several of the specific features explained in the following description.

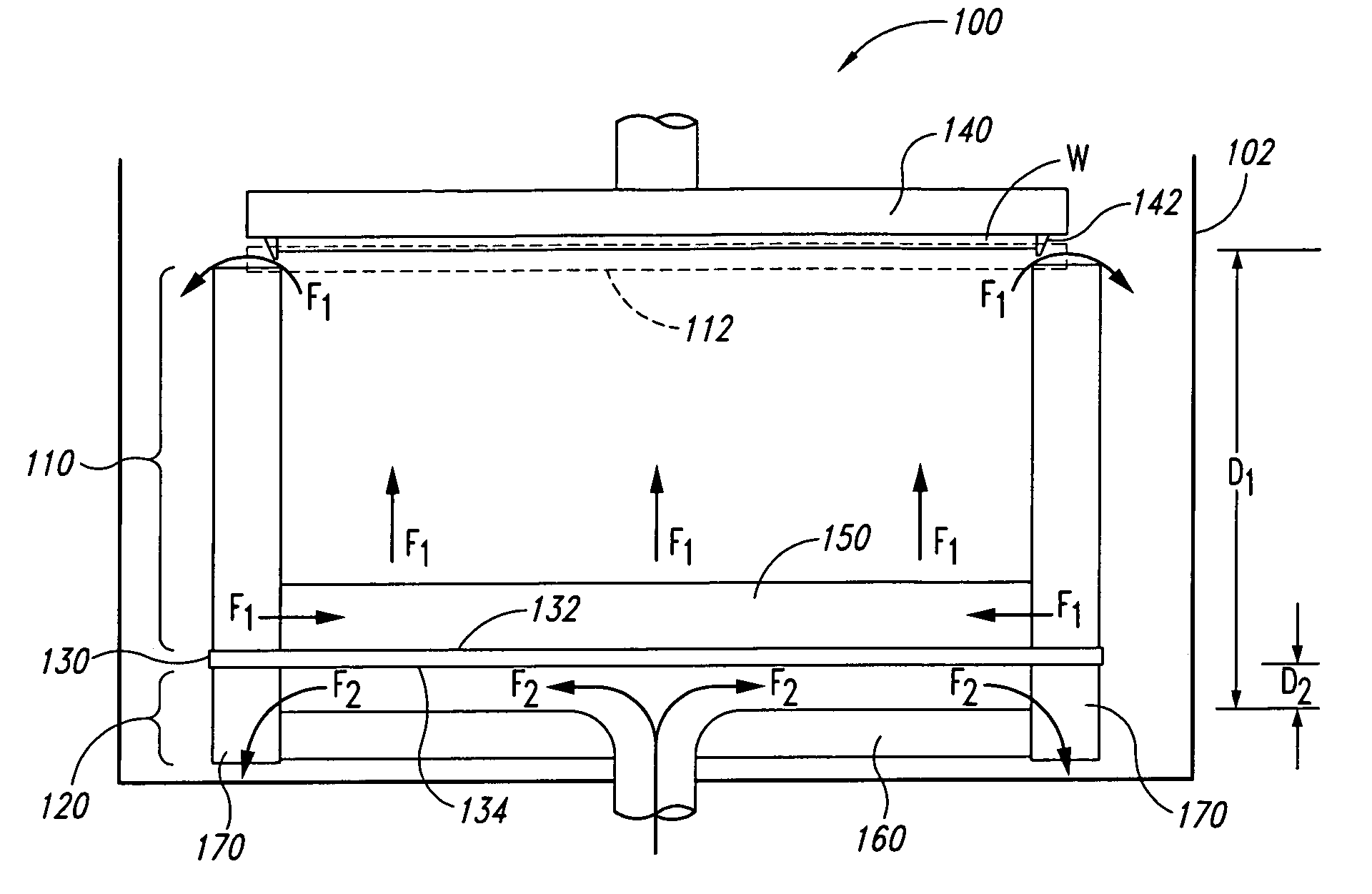

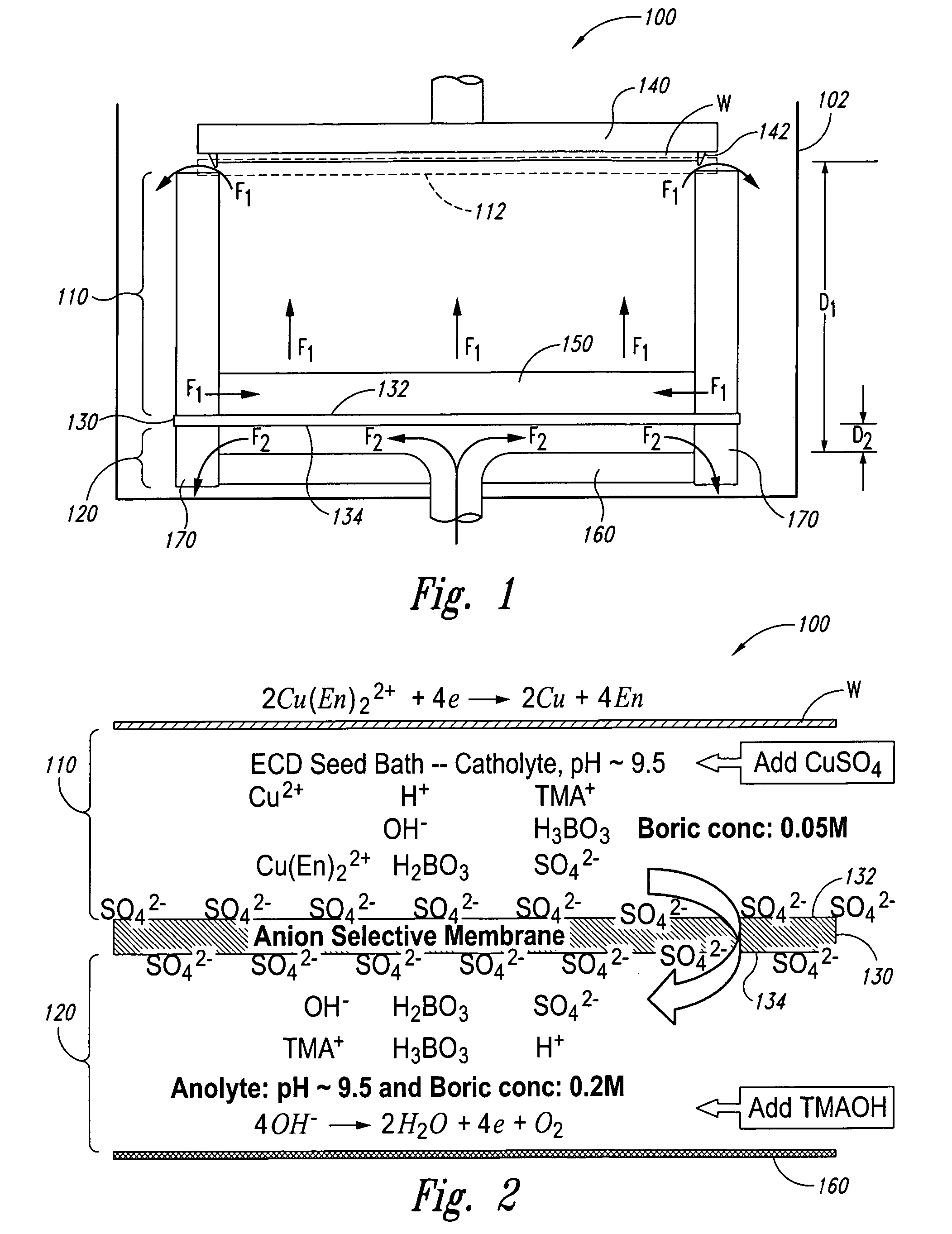

[0023]FIG. 1 schematically illustrates a reactor 100 for plating onto seed layers, directly onto barrier layers, or otherwise depositing other materials onto workpieces. The reactor 100 includes a vessel 102, a first chamber 110 configured to direct a flow of first processing solution to a processing zone 112, and a second chamber 120 configured to cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com