High Resolution Analytical Probe Station

a probe station and high-resolution technology, applied in the direction of fault location by increasing the destruction at fault, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problem that modern structures have now reached a size that no longer allows viewing with standard light microscopes, and the amount of unwanted insulator charging is getting larger. , to achieve the effect of reducing the duty cycle of high-resolution microscopes, reducing the risk of specimen damage, and reducing the amount of unwanted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

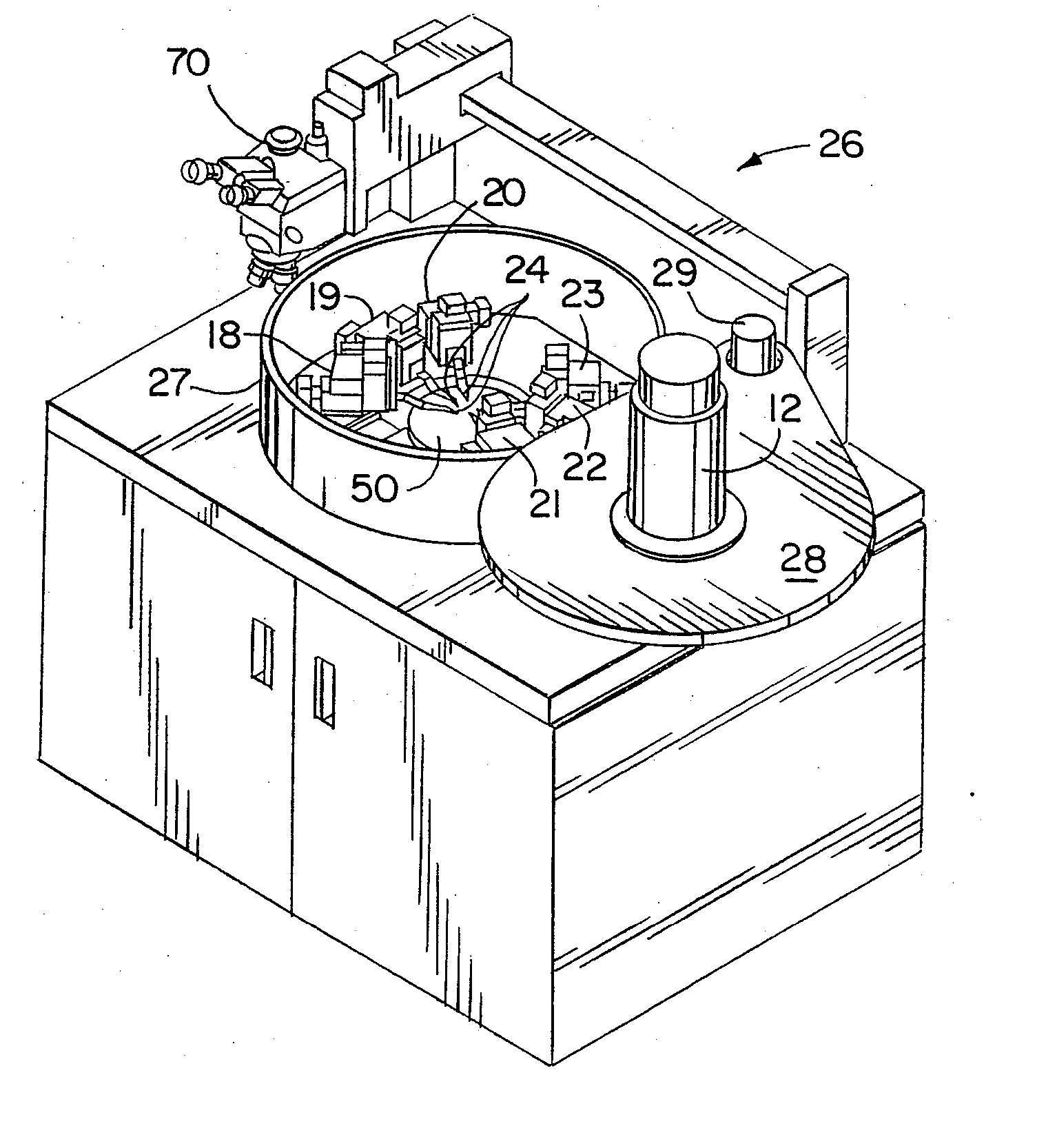

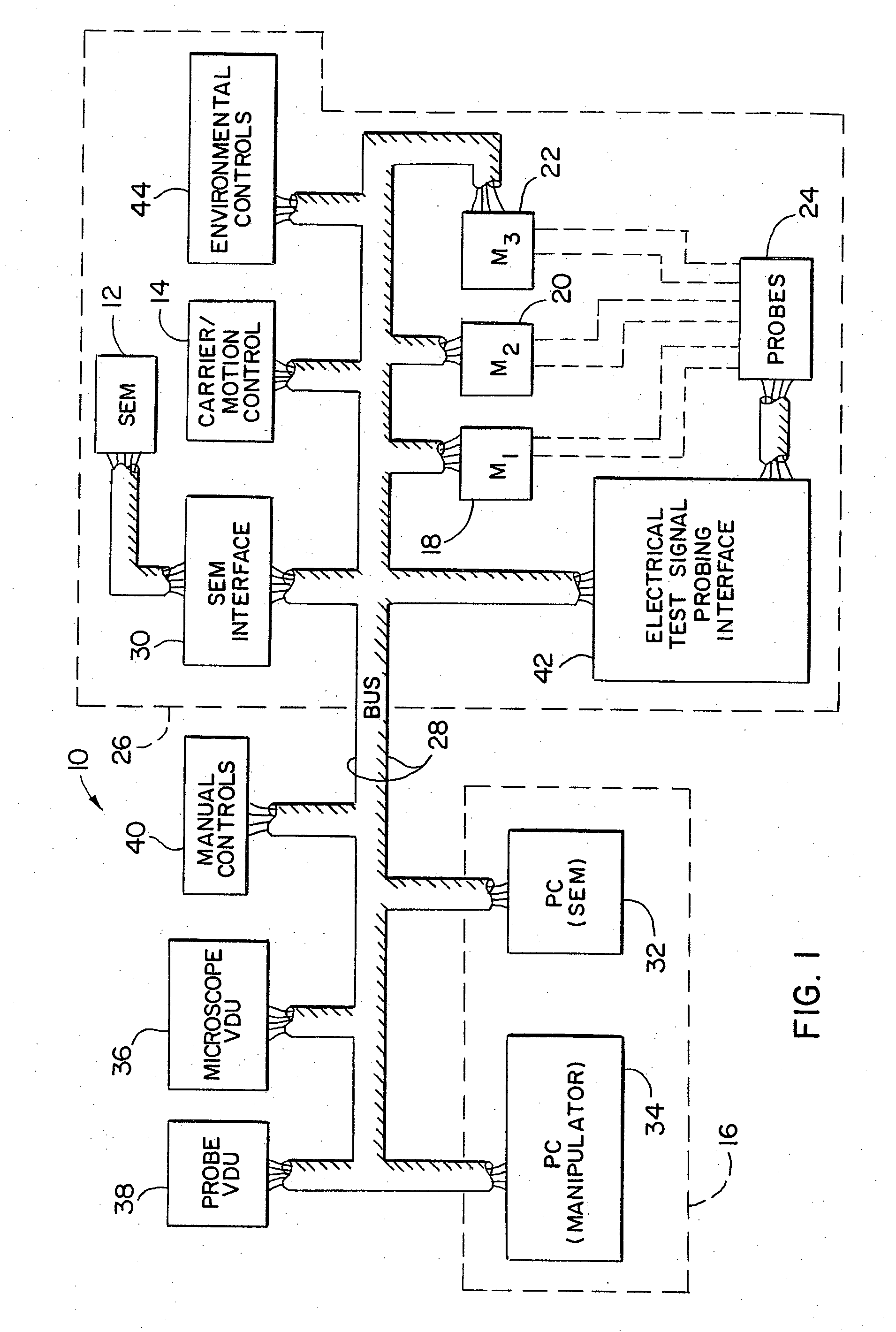

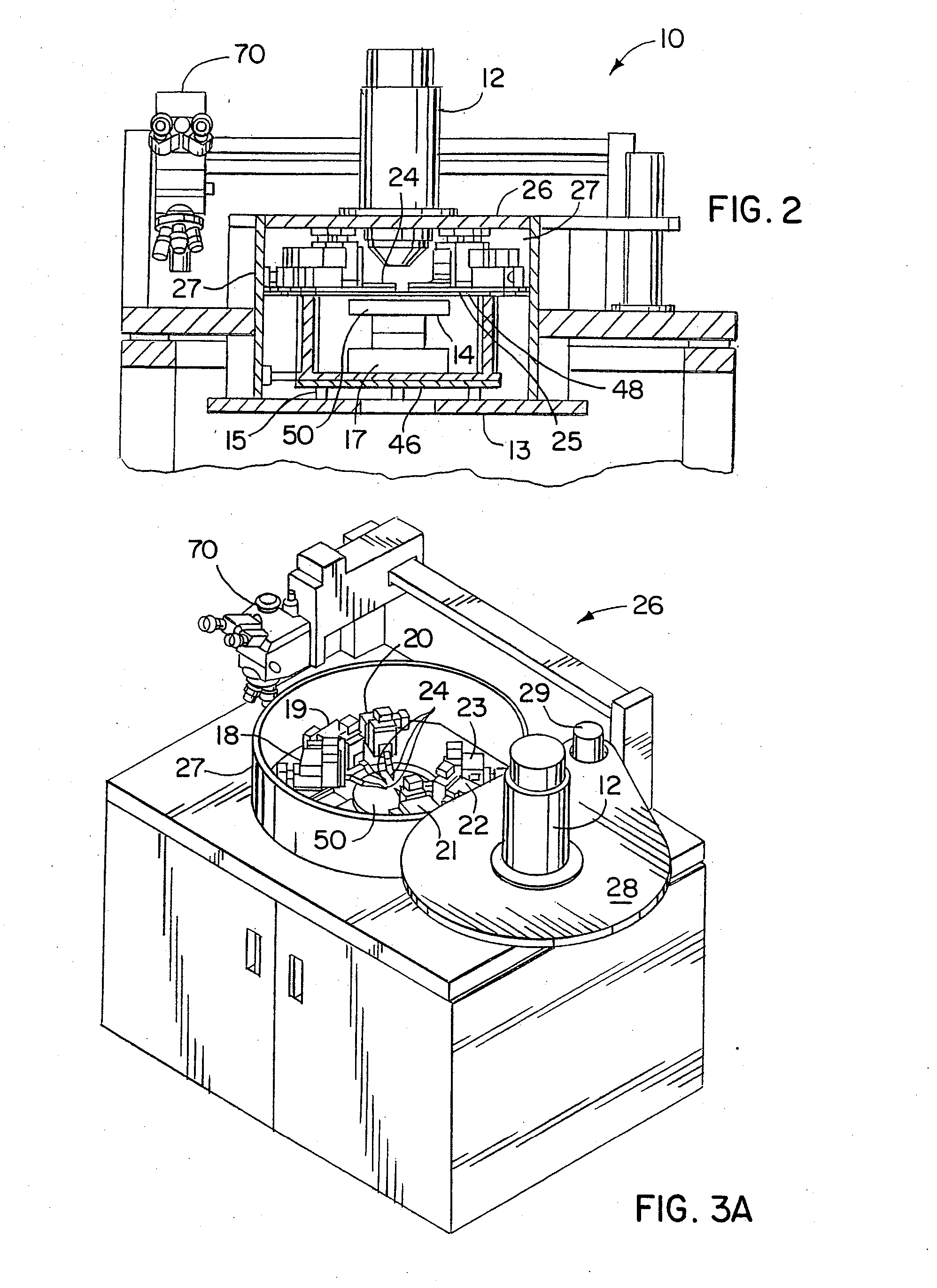

[0049] Referring to the drawings and especially to FIGS. 1 and 2, a system 10 is shown for high resolution analytical probing of an integrated circuit specimen, (e.g., a semiconductor wafer 50). The system 10 is capable of applying electrical test signals to an integrated circuit specimen 50, which may include whole wafers, packaged parts, or wafer fragments. Thus the system 10 may probe entire wafers in addition to a large variety of similarly sized specimens. A conventional scanning electron microscope (SEM), an X-ray microscope for material analysis during probing functions, or a Focus Ion Beam (FIB) system 12, may be employed for enhanced capabilities. Thus, the prober may be integrated into FIB systems as well as SEM systems. The embodiment described herein uses a SEM provided by R.J. Lee Instruments Ltd. which is positioned for observing a surface of the specimen 50 exposing electrically conductive terminals on the specimen 50. See, e.g., FIG. 4, discussed below. The system 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com