Inorganic fiber insulation product

a technology of organic fiber and insulation product, applied in the field of organic fiber insulation product, to achieve the effect of facilitating drying time, reducing mold growth potential, and reducing moisture sorption potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

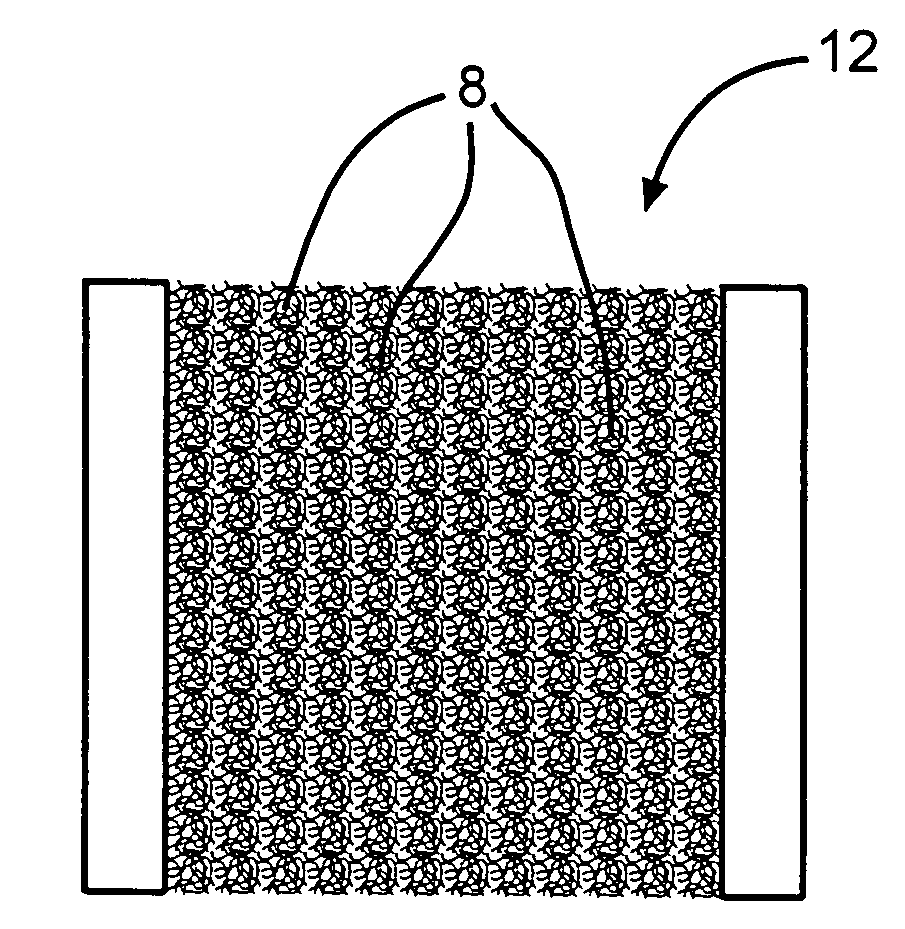

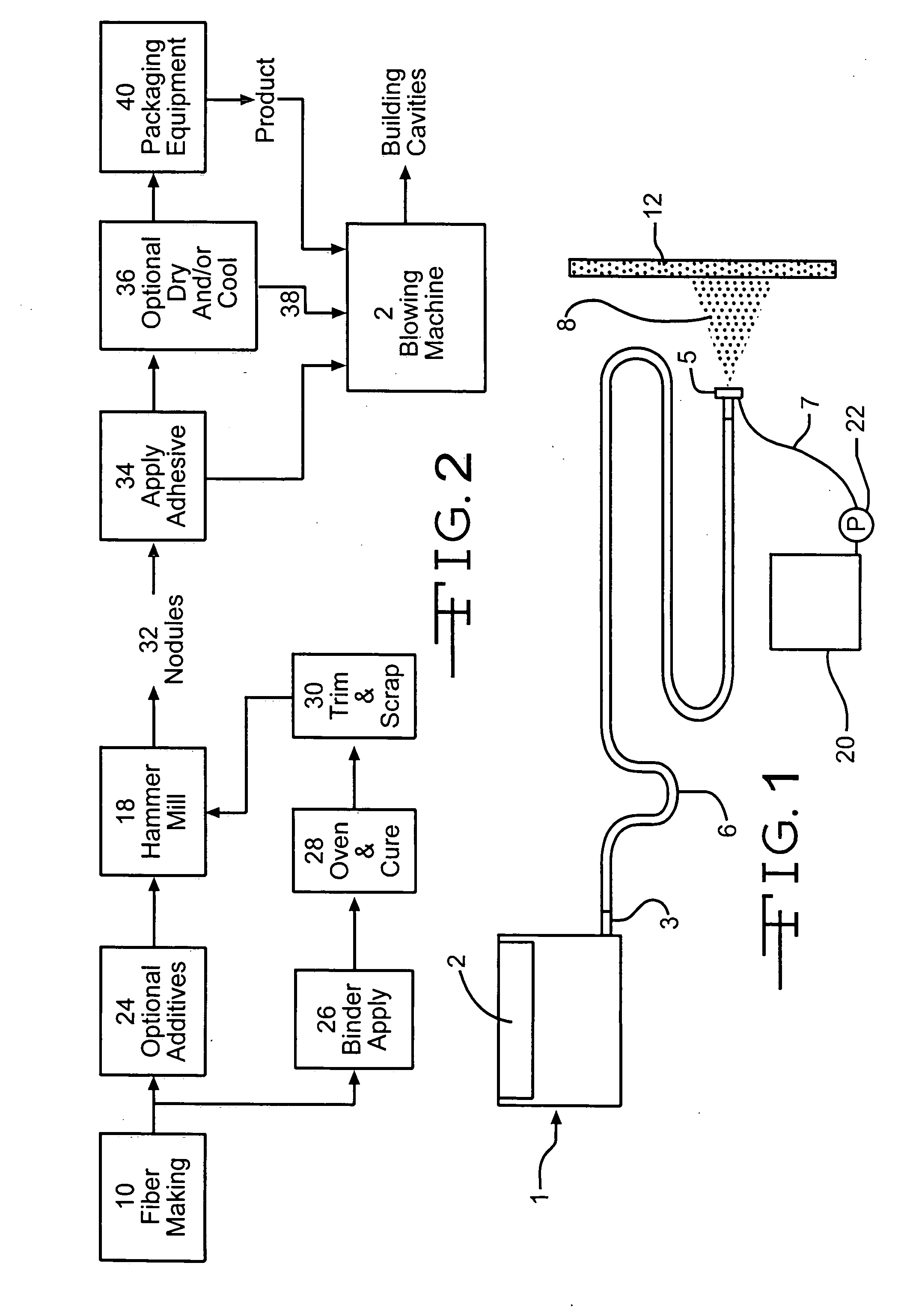

Image

Examples

example 1

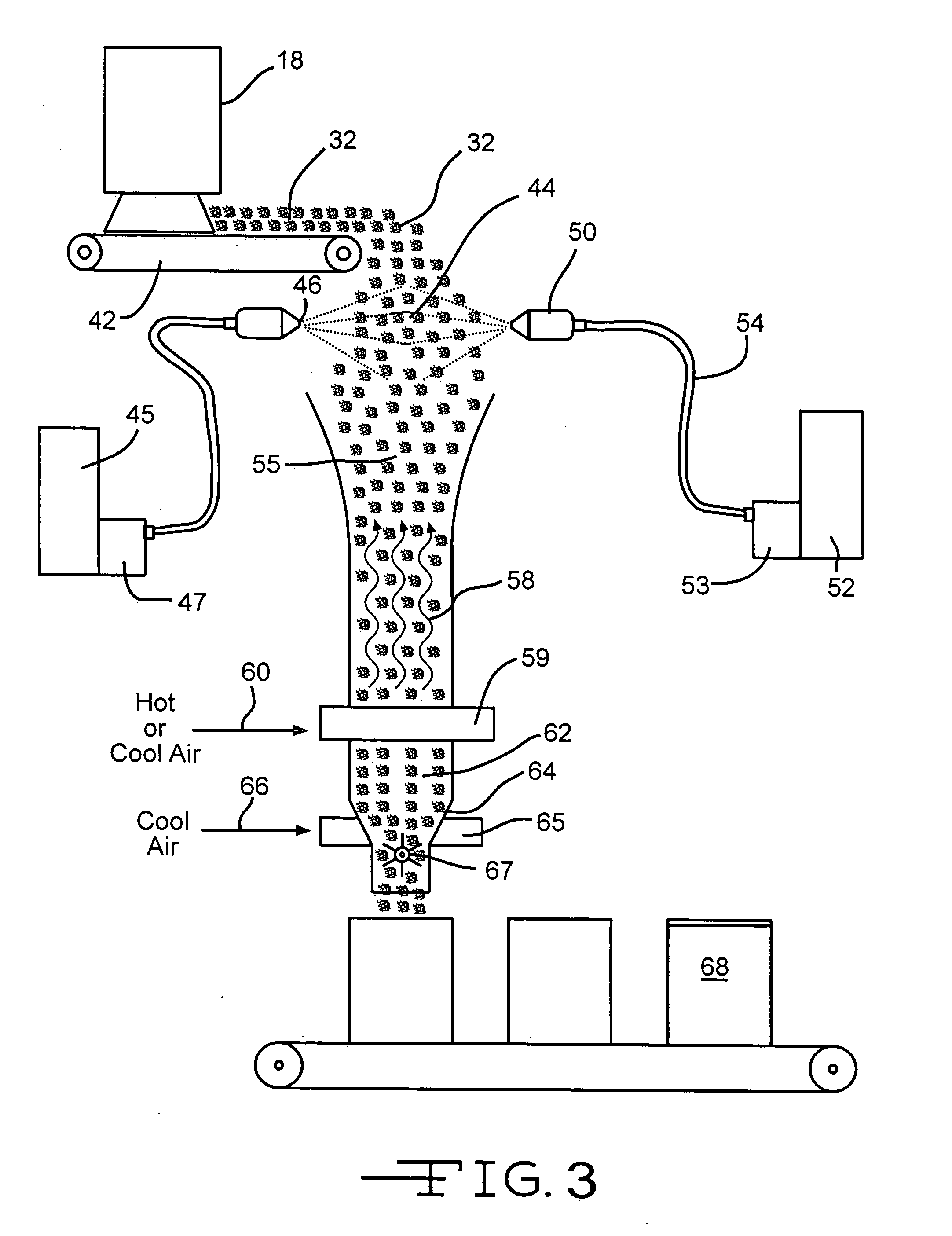

[0047]Virgin glass fiber having an average fiber diameter of 2 microns and made by a conventional process such as described in U.S. Pat. No. 4,058,386, is fed to a hammer mill containing an exit screen having hole diameters sized to produce nodules of one half inch and smaller diameters. These nodules are allowed to fall in front of a bank of hot melt adhesive spray heads spraying H.B. Fuller Co.'s NP 2255 remoistenable hot melt adhesive to coat the nodules. The remoistenable hot melt is applied to the falling nodules in a process like that illustrated in FIG. 3 using a bank of 20 ITW spray heads, each equipped with #109448 nozzles and 20 psi compressed air, delivering, for example, about 150 grams per minute of fiberized H.B. Fuller's NP 2255 hot melt across a 22-24 inch wide flow of falling nodules. Counter flow of cool air in a chamber beneath the spray zone rapidly solidifies the hot melt web on the surface of the fibrous insulation nodules to produce reactivatable coated fibero...

example 2

[0048]A moisture activated envelope flap type adhesive such as Dyna-Tech™ Flextac™ 272 or 7465 is spray applied to fiberglass nodules like those described in Example 1. These adhesives are water based and are pumped to spray jets with a pump as shown in FIG. 3. The adhesives have solids contents of 55% or more, therefore the coated nodules dry very fast when sprayed onto hot nodules, or when the coated nodules are subjected to a counter flow of hot air, to produce reactivatable adhesive coated insulation nodules.

example 3

[0049]As shown in FIG. 4, nodules of inorganic fibrous insulation, either virgin fiber or fiber bonded with a dried and cured resin in the form of trim or scrap, are fed into a nodulating machine such as a hammer mill containing an exit screen to produce fibrous insulation nodules having a diameter of less than about ½ inch. These nodules are then either fed into packaging equipment or directly into an insulation blowing machine. The nodules are suspended in air and blown through a hose. As they exit the hose, or an optional nozzle, the nozzles are spray coated with sprays of reactivatable adhesive in the form of either a molten hot melt or a solution or a liquid suspension of reactivatable adhesive particles as described in Examples 1 and 2. The coated nodules are then allowed to drop through a chamber against a counter flow of either hot air to dry the coating or a cool air to solidify the coating. The coated nodules are then collected and fed into packaging equipment that compres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com