Compositions and methods for extracting hydrocarbons from oil sands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

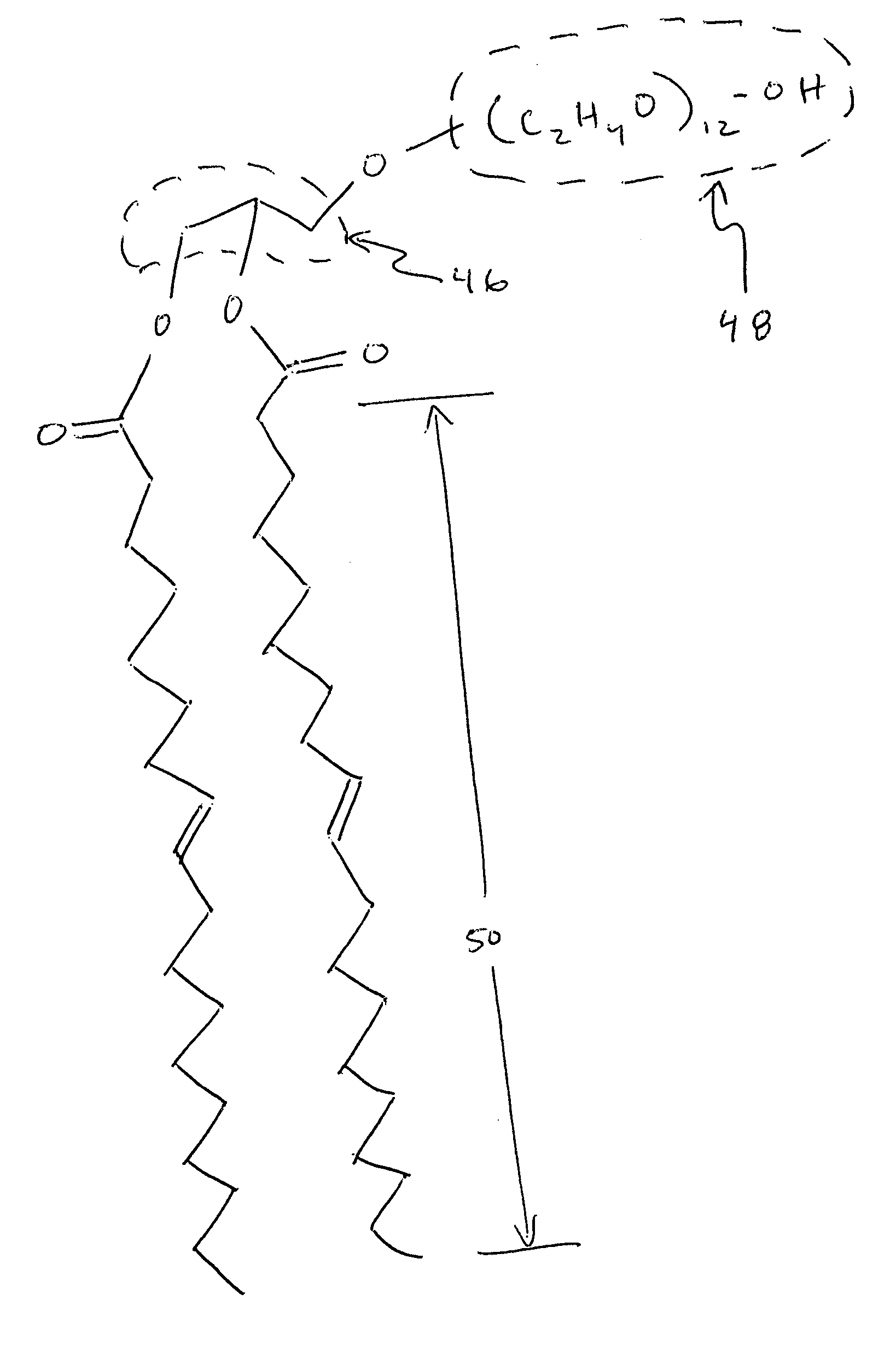

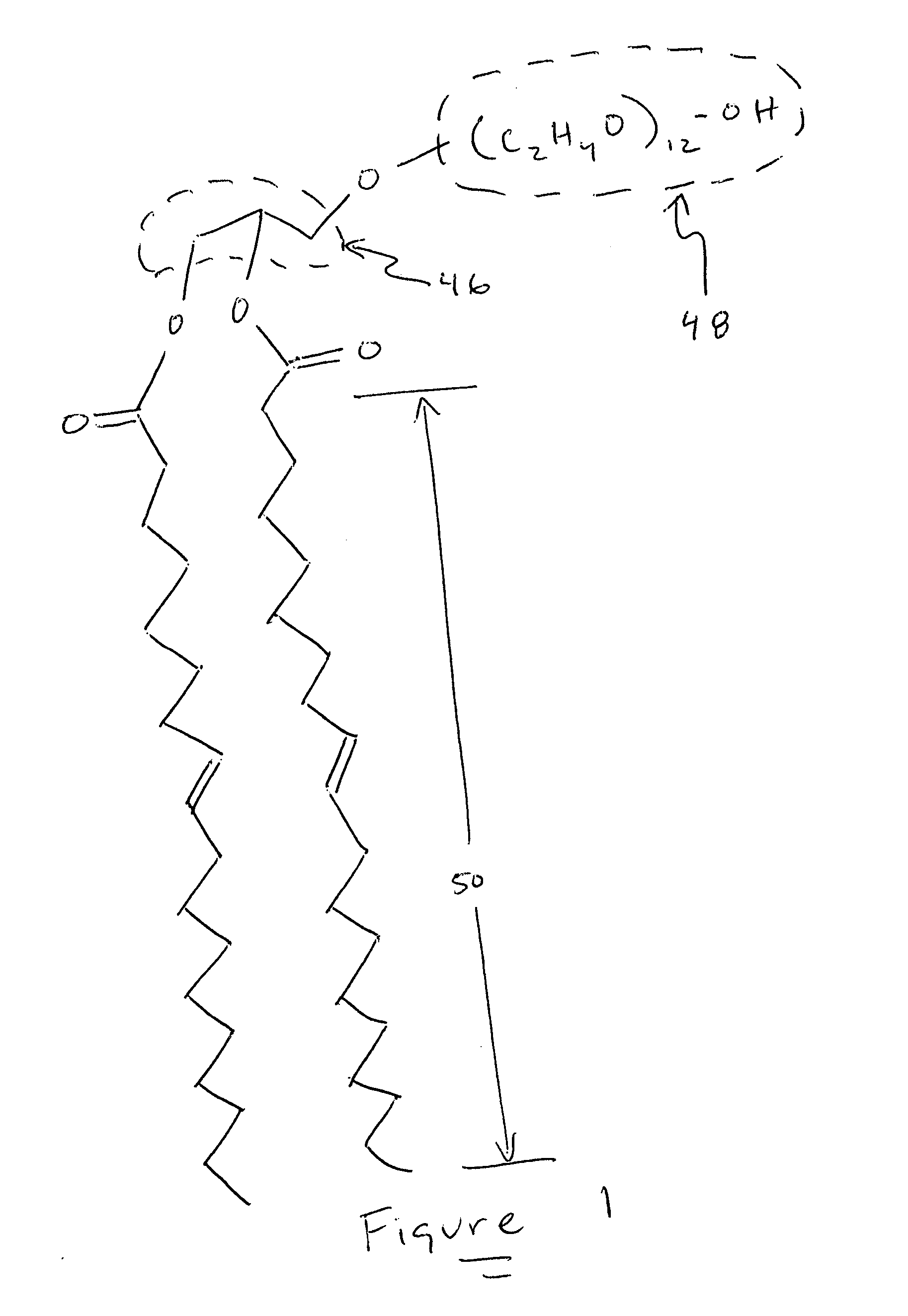

Image

Examples

example 1

Entrapment and Dispersion of Oil in Water

[0056] HD 30 motor oil was added to water. Then PEG-12 GDO was added in a 1:4 ratio (oil:PEG-12 GDO). An opaque white suspension formed which showed liposomes when examined under a light microscope at 600×. The oil was entrapped and dispersed in the suspension.

example 2

Cleaning an Environmental Oil Spill (Predictive)

[0057] A large quantity of medium weight crude oil is spilled from a ruptured tanker and the oil washes onto a coastal area. The water temperature is 45 degrees C. and the air temperature is 50 degrees. The beach is sprayed with diacyl lipid-PEGs to disperse the oil, thereby forming liposomes.

example 3

Recovery of Hydrocarbons from Oil Sand

[0058] These experiments were conducted at room temperature, about 22° C.

[0059] The objective of this experiment was to test various non-toxic solvents for their ability to release bitumen from Canadian oil-sand.

[0060] The goal of this experiment was to find the relative solvent capability of various solvents and compare them to identify the best solvents for the purpose of releasing bitumen from oil-sand at low energy expense and decreased green-house gas release.

[0061] Table 1 lists the solvents tested. All solvents were fluids at ambient temperature. A weighed amount of each solvent (between 15 grams and 35 grams) was put into a Pyrex mortar and pestle. An equal amount of Canadian oil-sand was weighed and put into the solvent. The 1:1 mixture was left to stand for 10 minutes then triturated for 2 minutes and left to stand for 10 minutes. Solubility was graded by observation of the color of the liquid which correlates to the amount of bitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com