In-situ oxidized textured surface for prosthetic devices

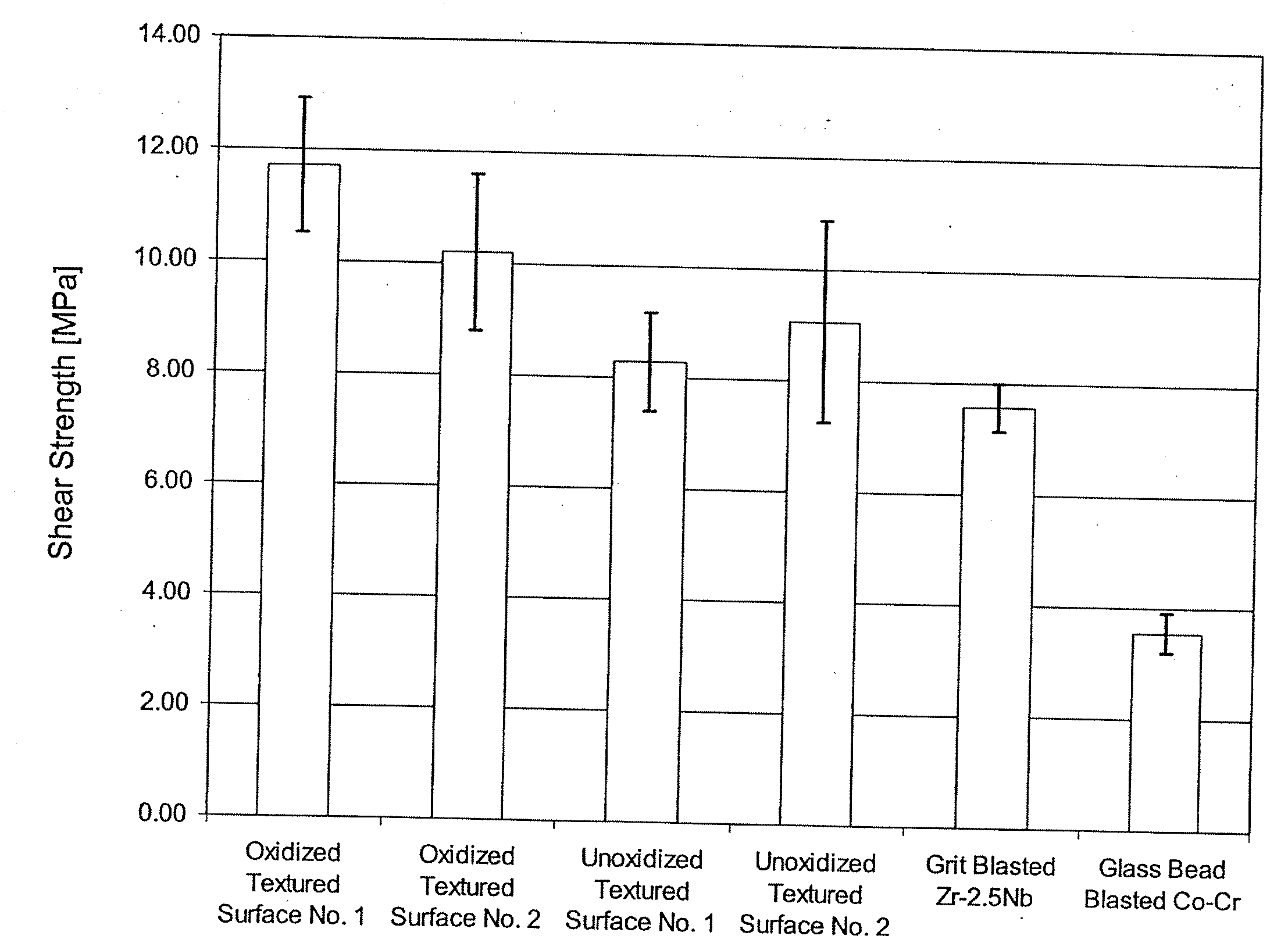

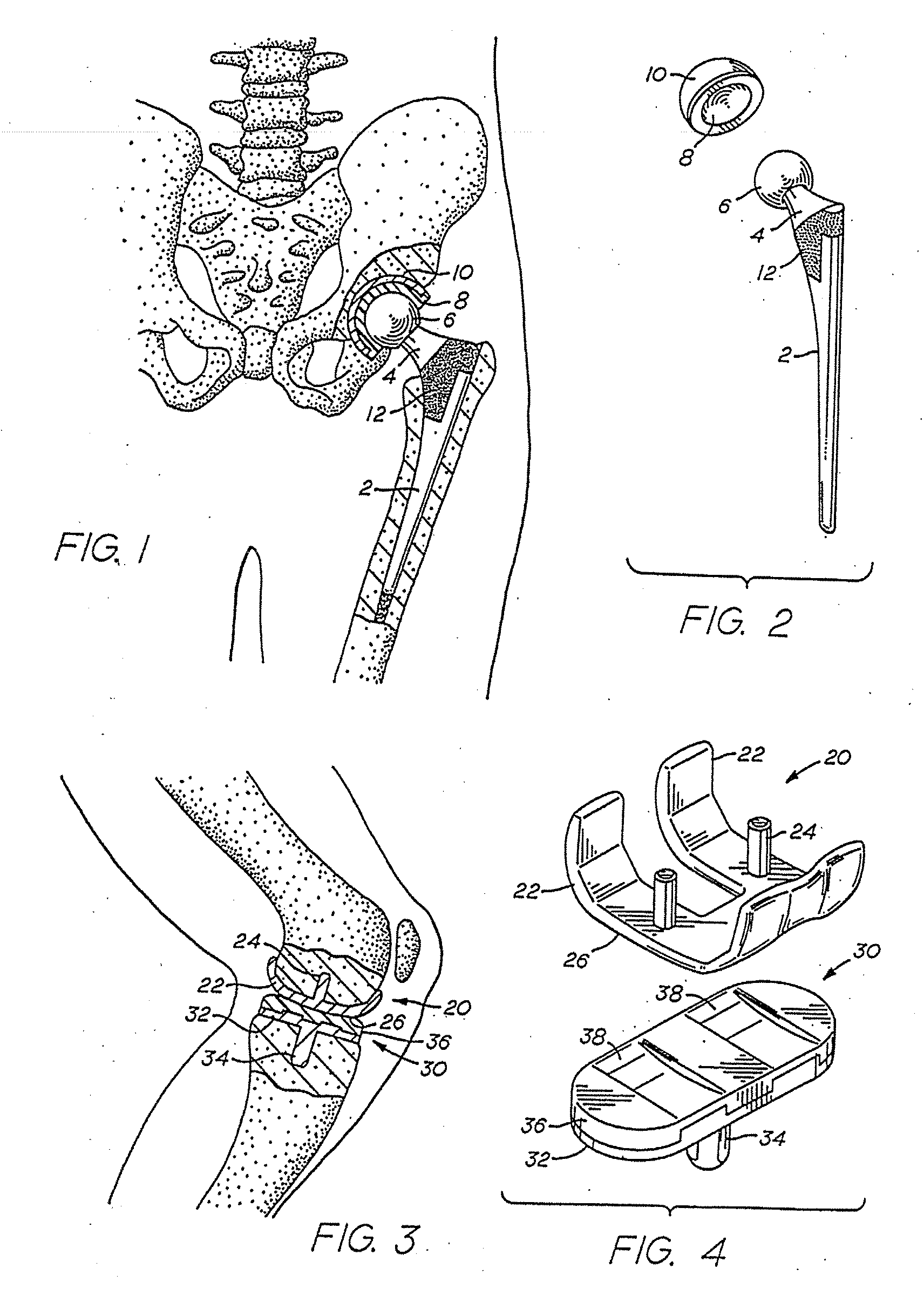

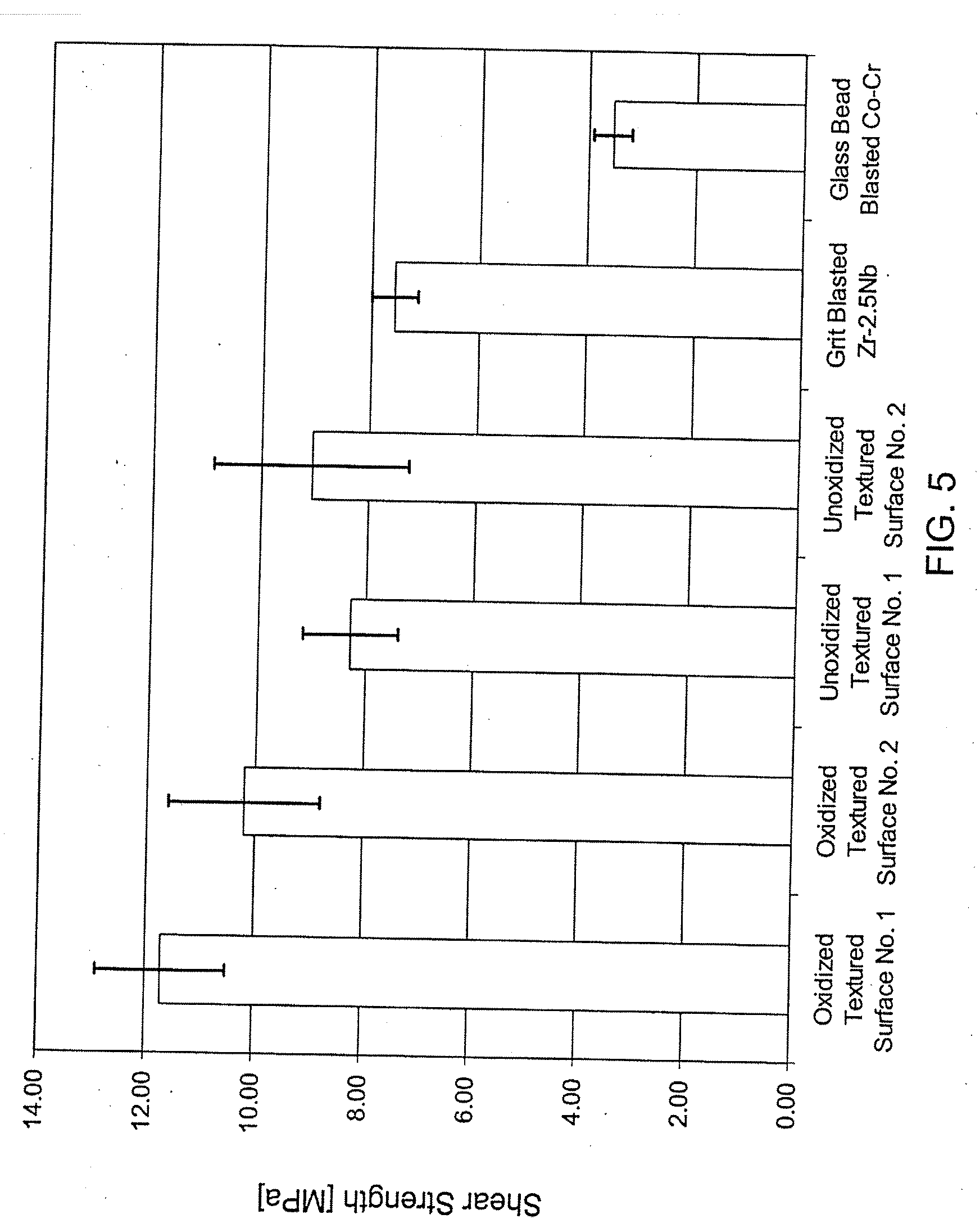

a prosthetic device and textured surface technology, applied in the field of orthopedic implants, can solve the problems of metal ion release from the prosthesis, increase the friction of microfretted metal particles, and the rate of wear of load bearing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] As used herein, “a” or “an” may mean one or more. As used herein in the claim(s), when used in conjunction with the word “comprising”, the words “a” or “an” may mean one or more than one. As used herein, “another” may mean at least a second or more.

[0042] As used herein, the term, “medical implant” includes any device for implantation into the body. It is broader than and inclusive of prosthetic devices and includes bone plates and bones screws and related devices.

[0043] As used herein, “metallic” may be a pure metal or an alloy.

[0044] As used herein, the term “texture modified” in reference to a surface is defined as a native surface which has been treated by techniques known in the art to enhance bone in-growth and on-growth to improve fixation stability. It does not include those methods which modify the native surface solely by the addition of extraneous material, either of the same or different composition as that of the native surface, such as by the incorporation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com