Method Of Serving A Slushy Drink And A Product For Use In Such

a technology of slushy drink and product, which is applied in the field of serving slushy drink and a product for such, can solve the problems of uncomfortably cold handling of flexible and deformable containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0082]In this example, various modes of transforming a frozen product into a slushy drink were evaluated. Four modes of transformation were evaluated: stirring, shaking, squeezing and kneading.

Containers

[0083]The containers used for the stirring tests were simple plastic cups (PET high-clarity tumblers supplied by Huhtamaki, Ronsberg, Germany) having a brim full capacity of 290 ml. These containers are referred to as Container A.

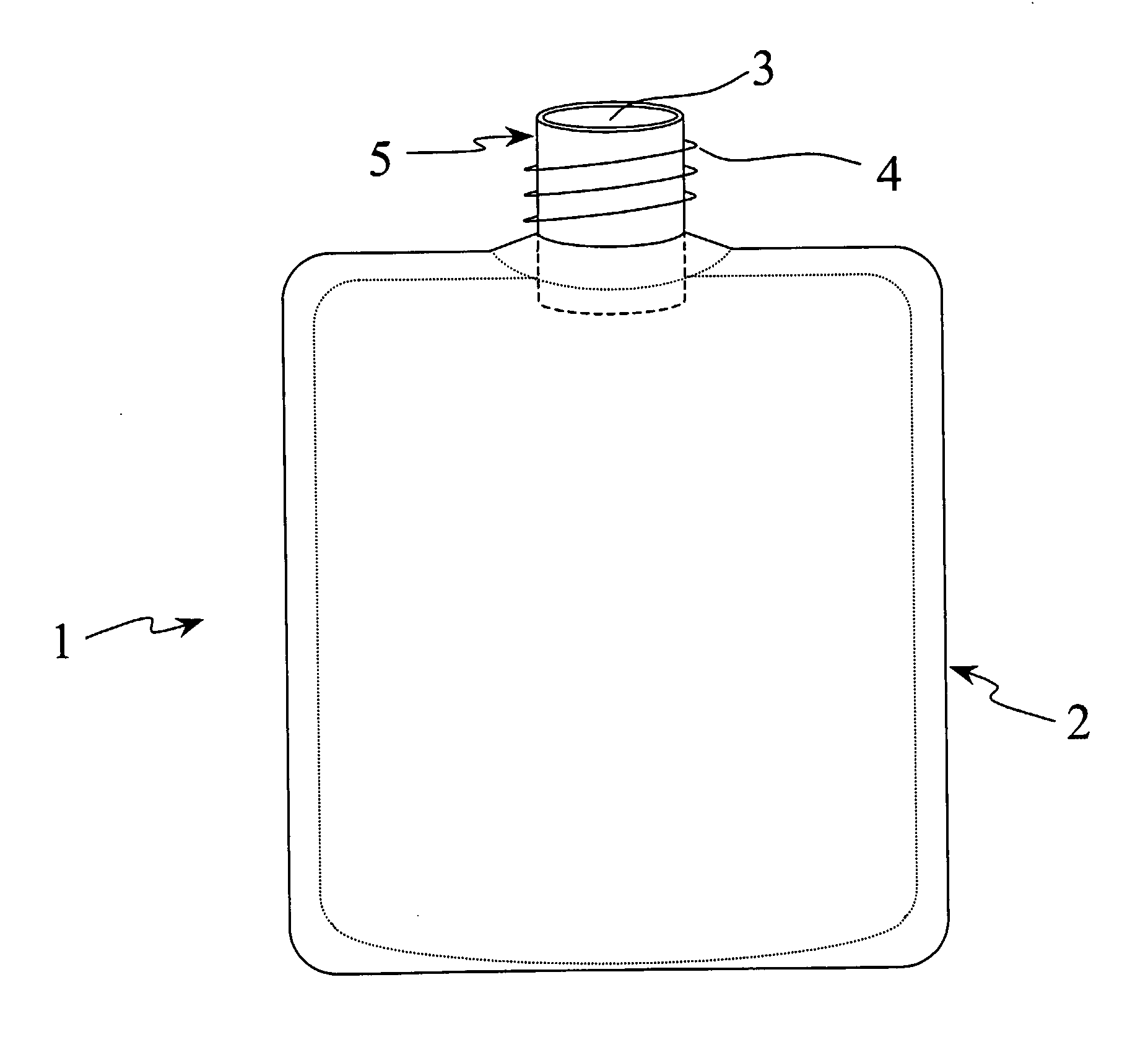

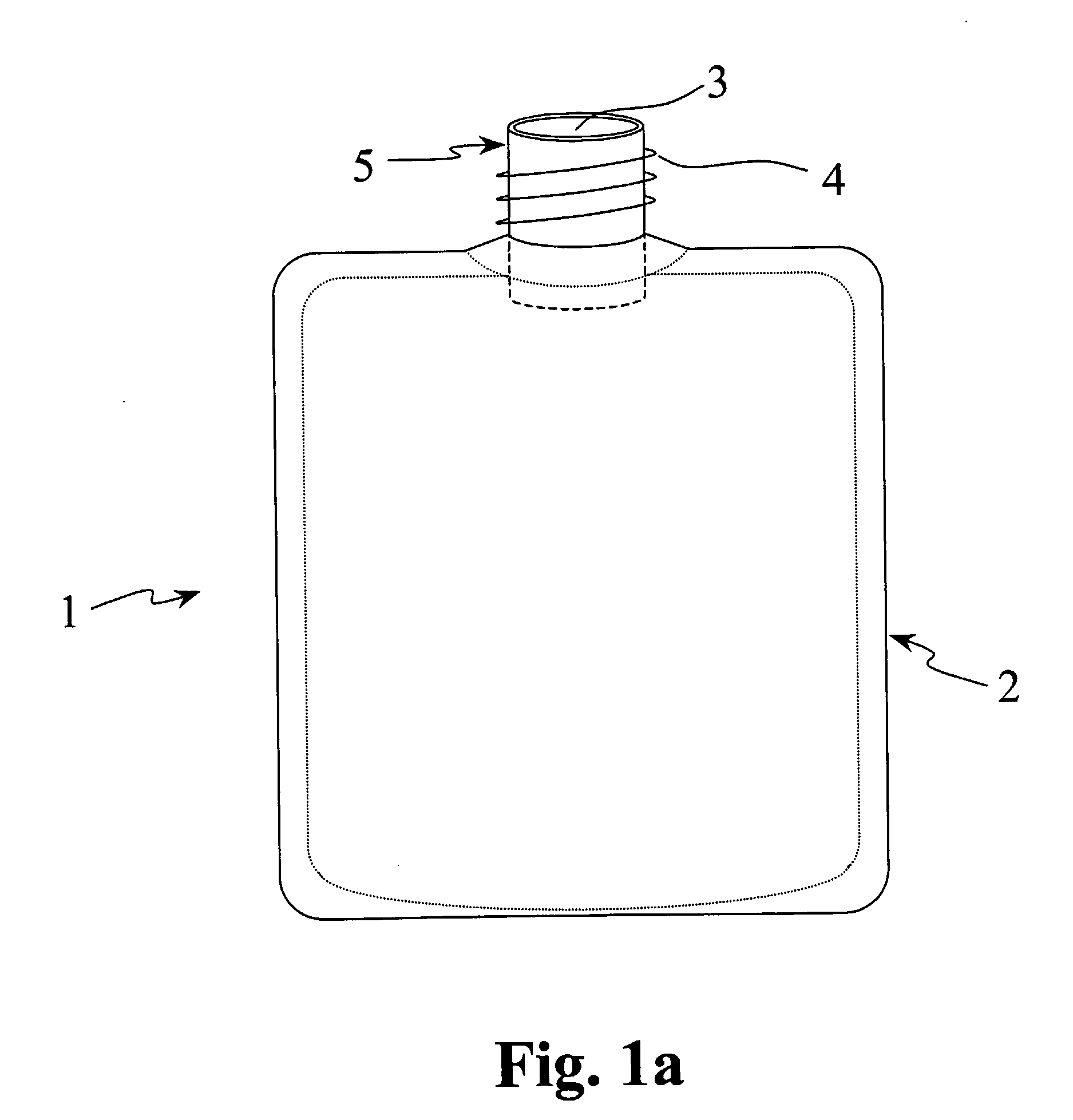

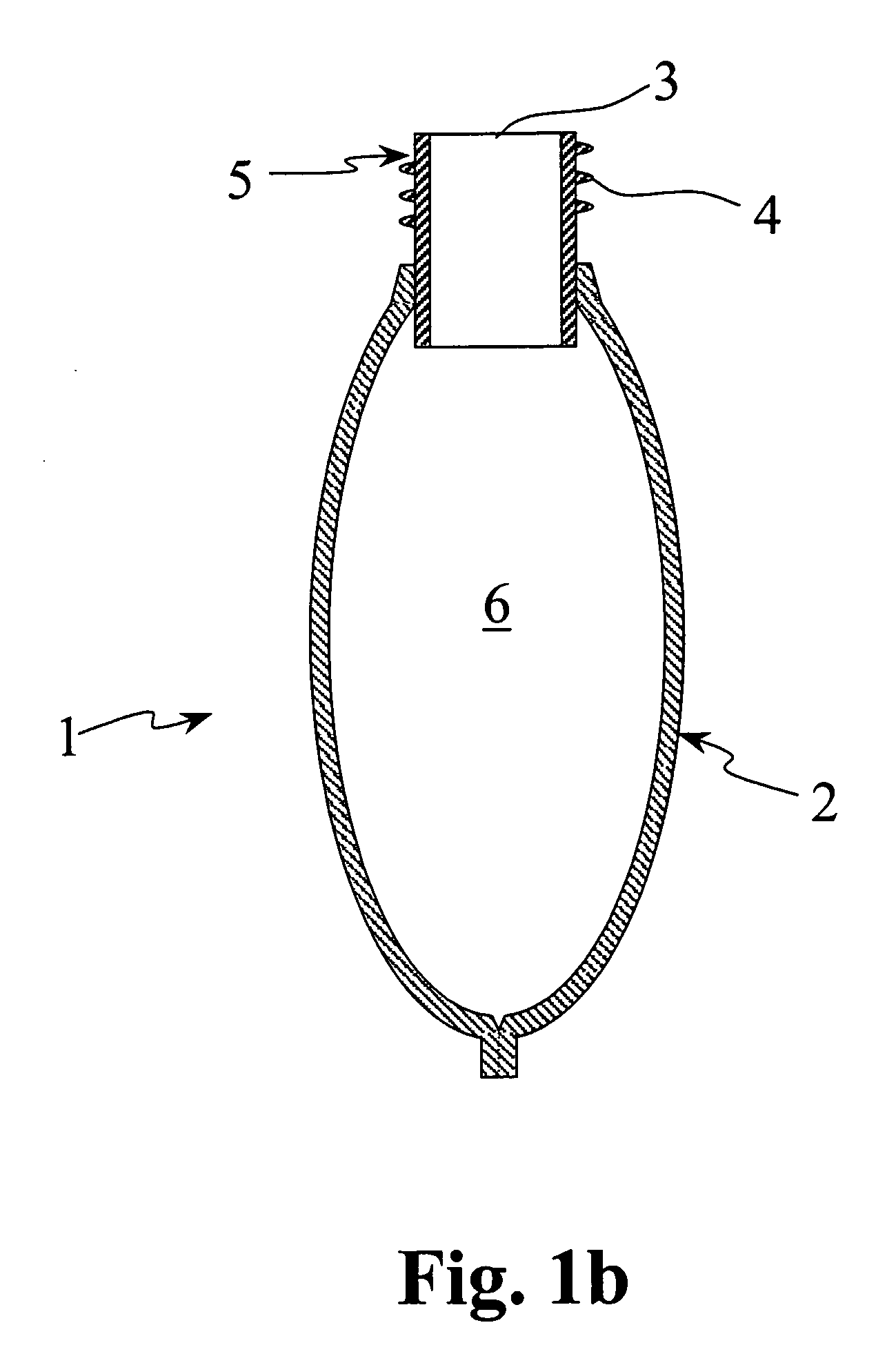

[0084]FIGS. 1a and 1b show a container (1) similar to those used for the kneading tests. The container (1) comprises a flexible pouch or tube (2) forming a wall delimiting a cavity (6). The pouch (2) is in sealing engagement with a spout (5) which has a product outlet (3) in fluid communication with the cavity (6) and is threaded (4) to receive a sealing cap (not shown). The containers used in the tests were flexible LDPE tubes as used for applying Vanish™ stain remover gel (Reckitt Benckiser, Mannheim, Germany) and having a brim full capacity of 235 ml. The...

example 2

[0112]In this example two fruit-based smoothies according to the invention are described.

Containers

[0113]All products were packaged in PET bottles having a brim full capacity of 250 ml and similar to the container shown in FIG. 2.

Formulations

[0114]All concentrations are given on a w / w basis.

[0115]Specialist materials were as follows:[0116]Low Fructose Corn Syrup was C*TruSweet 017Y4, had a moisture level of 22%, a DE of 63 and was supplied by Cerester, Manchester, UK.[0117]Whey Powder was Avonol™ 600 Whey powder supplied by Glanbia Ingredients (Ballyragget, Co. Kilkenny, Ireland), and has a moisture content 3.7%, a lactose content of 53% and a protein content of 31%.[0118]Strawberry Puree was supplied by SVZ International BV (Holland) and was an aseptically filled, seedless, single-strength puree having a water content of 89%, a sucrose content of 0.9%, a dextrose content of 2.2% and a fructose content of 2.3%.[0119]Iota Carrageenan was Deltagel™ P388, supplied by Quest Internationa...

example 3

[0129]This example describes a milkshake according to the invention.

Container

[0130]The container used was as in Example 2.

Formulation

[0131]All concentrations are given on a w / w basis. Specialist materials were as in Example 2.

[0132]A strawberry flavoured frozen product was prepared having the formulation given in Table V.

TABLE VMilkshakeDextrose Monohydrate (%)12.60Low Fructose Corn Syrup (%)14.10Skimmed Milk Powder (%)4.00Whey Powder (%)4.40Coconut Oil (%)8.00Iota Carrageenan (%)0.12Guar Gum (%)0.10Monoglyceride Emulsifier(%)0.30Strawberry Puree (%)15.00Beetroot Red Colour (%)0.10Citric Acid (%)0.15Flavour (%)0.12Water (%)41.01FPDS (%)27.5n (g mol−1)232

Slush Manufacture

[0133]All ingredients except for the puree, flavour, acids, fat and emulsifiers were combined in an agitated heated mix tank. The fat was then melted and emulsifiers added to the liquid fat prior to pouring into the mix tank. The mix was subjected to high shear mixing at a temperature of 65° C. for 2 minutes. The mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com