Article comprising conductive conduit channels

a technology of conductive conduit and conduit, which is applied in the direction of conductive pattern formation, dielectric characteristics, flexible circuits and rigid printed circuits, etc., can solve the problems of insufficient other applications, insufficient size requirements for semiconductors and the means for providing electrical connection between semiconductors and substrates, and insufficient light transmission, etc., to protect the delicate transparent conductive coating and improve light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

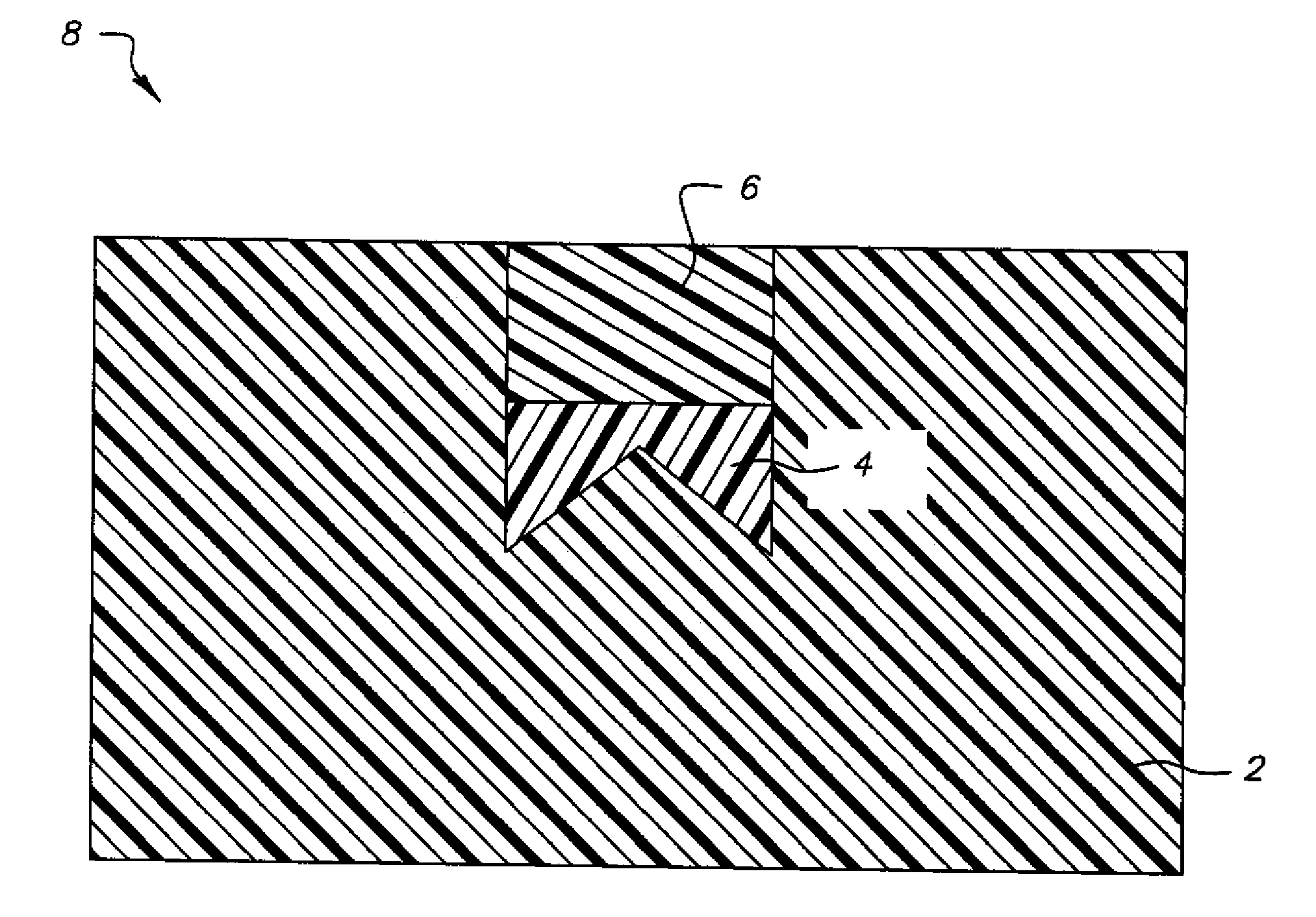

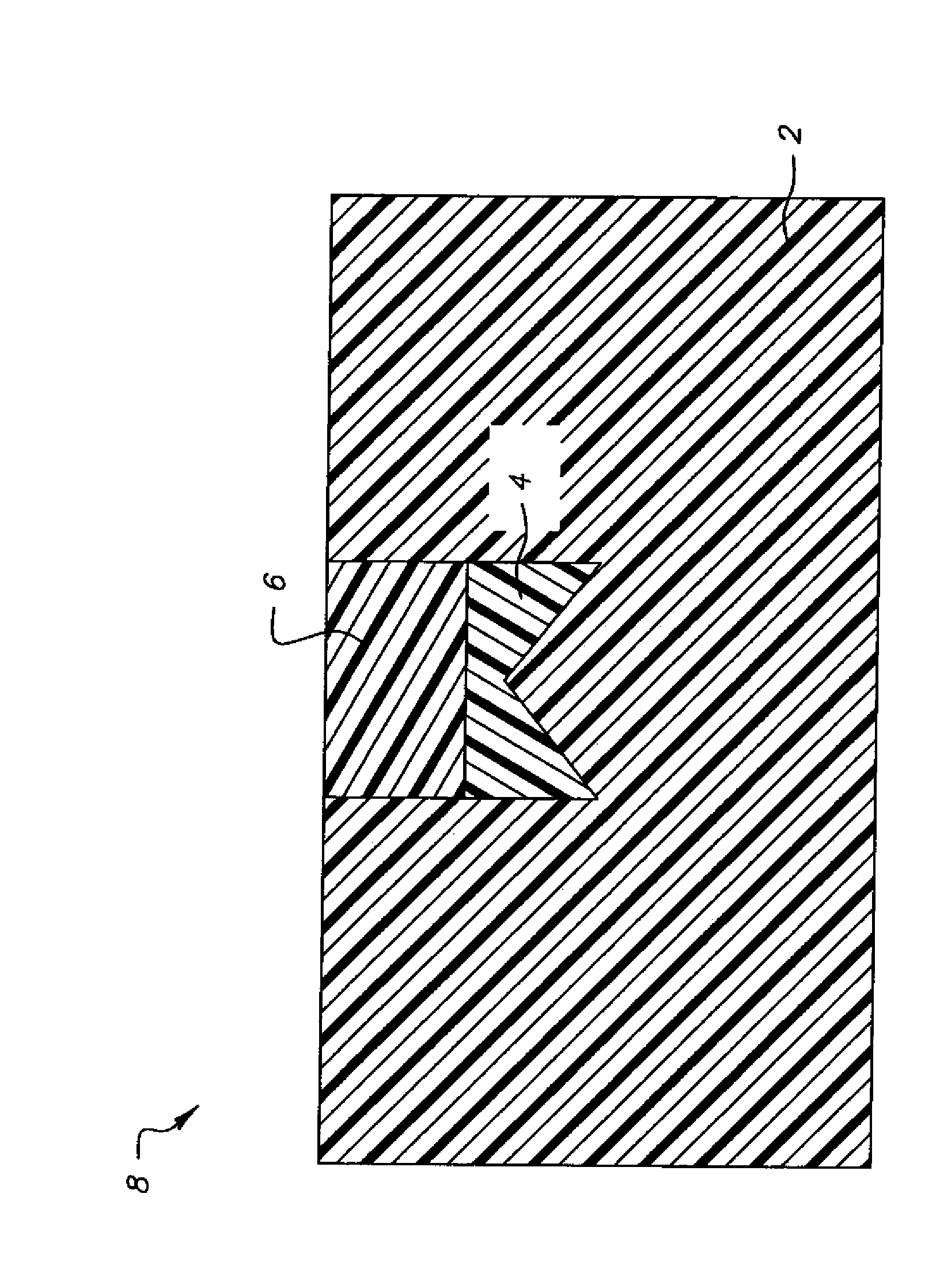

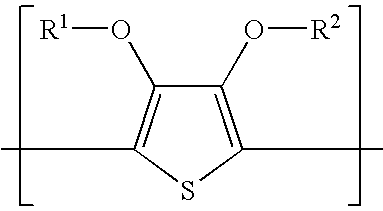

[0092] In this example, polycarbonate V shaped conduits were formed integral to a polycarbonate 100 micrometer sheet. A conductive, transparent form of polythiophene was applied into the V shaped conduits creating a transparent conductive sheet. This invention will demonstrate the conductive and transmissive properties of the polymer sheet containing the conductive, transparent polymer.

[0093] The V shaped conduits were made by casting melted polycarbonate against a heated roller containing the negative of the V groove pattern. The V-groove patterned roller was manufactured by precision machining, utilizing a wire EDM cutting tool, the negative of the V groove pattern into the surface of a smooth steel roller.

[0094] The V groove patterned roller was used to create the integral polycarbonate conduits by extrusion casting a polycarbonate polymer from a coat hanger slot die comprising substantially 98.0% 68 melt index CD grade polycarbonate (Bayer Chemical), 1.5% antioxidant and 0.5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com