Zirconium alloy composition having excellent corrosion resistance for nuclear applications and method of preparing the same

a technology of zirconium alloys and corrosion resistance, which is applied in the direction of nuclear elements, nuclear fuel reduction, and greenhouse gas reduction, etc., can solve the problems of increasing the number of severe corrosion of nuclear fuel, the development of zirconium alloys, and the need for zirconium alloys, etc., to achieve excellent corrosion resistance, excellent corrosion resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Zirconium Alloy

[0057](1) Preparation of Ingot

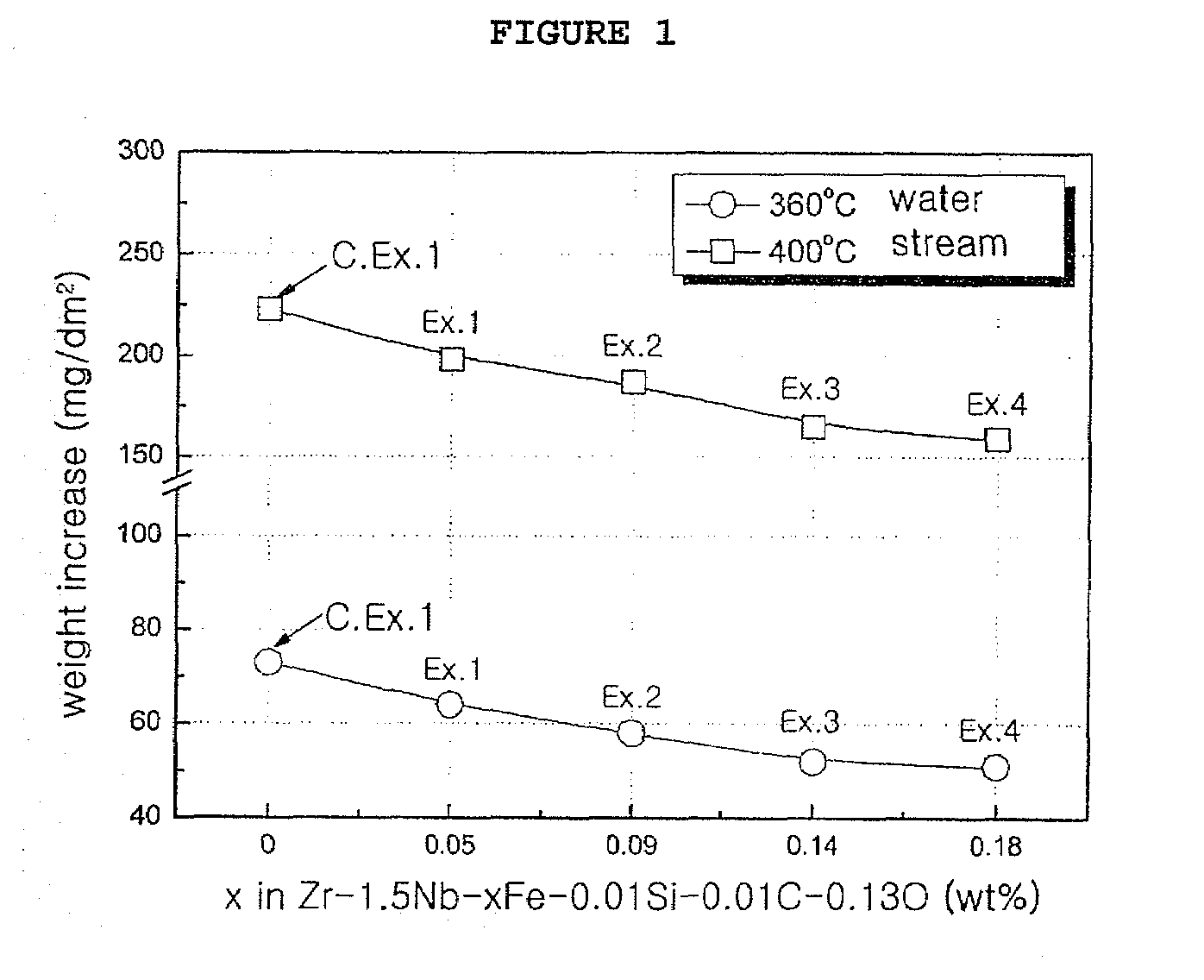

[0058]A zirconium alloy composition, comprising 1.58 wt % of niobium, 0.05 wt % of iron, 0.01 wt % of silicon, 0.01 wt % of carbon, and 0.13 wt % of oxygen, with the balance being zirconium, was subjected to VAR to thus prepare an ingot having a weight of 200 g in a button shape. As such, as zirconium, reactor grade sponge zirconium, described in ASTM B349, was used, and the alloying elements had high purity of 99.99% or more. In addition, silicon, carbon, and oxygen were subjected along with sponge zirconium to first melting to thus prepare a mother alloy, which was then added in a desired amount upon ingot melting. In order to prevent the segregation of impurities or the non-uniform distribution of the alloy composition, the melting process was repeated four times. Further, in order to prevent the oxidation upon the melting process, the vacuum state in a chamber was maintained at 1×10−5 torr, argon gas having high purity ...

example 2

[0067]The present example was performed in the same manner as in Example 1, with the exception that a zirconium alloy composition, comprising 1.51 wt % of niobium, 0.09 wt % of iron, 0.01 wt % of silicon, 0.01 wt % of carbon, and 0.13 wt % of oxygen, with the balance being zirconium, was used.

example 3

[0068]The present example was performed in the same manner as in Example 1, with the exception that a zirconium alloy composition, comprising 1.72 wt % of niobium, 0.14 wt % of iron, 0.01 wt % of silicon, 0.01 wt % of carbon, and 0.13 wt % of oxygen, with the balance being zirconium, was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com