Contact barrier layer deposition process

a technology of contact barrier layer and deposition process, which is applied in the direction of basic electric elements, semiconductor/solid-state device manufacturing, electrical equipment, etc., can solve the problems of affecting the reliability of the resulting ics, uniform tin layer being deposited across the si substrate surface,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.”

BRIEF DESCRIPTION OF THE DRAWINGS

[0014]For a more complete understanding of the principles disclosure herein, and the advantages thereof, reference is now made to the following descriptions taken in conjunction with the accompanying drawings, in which:

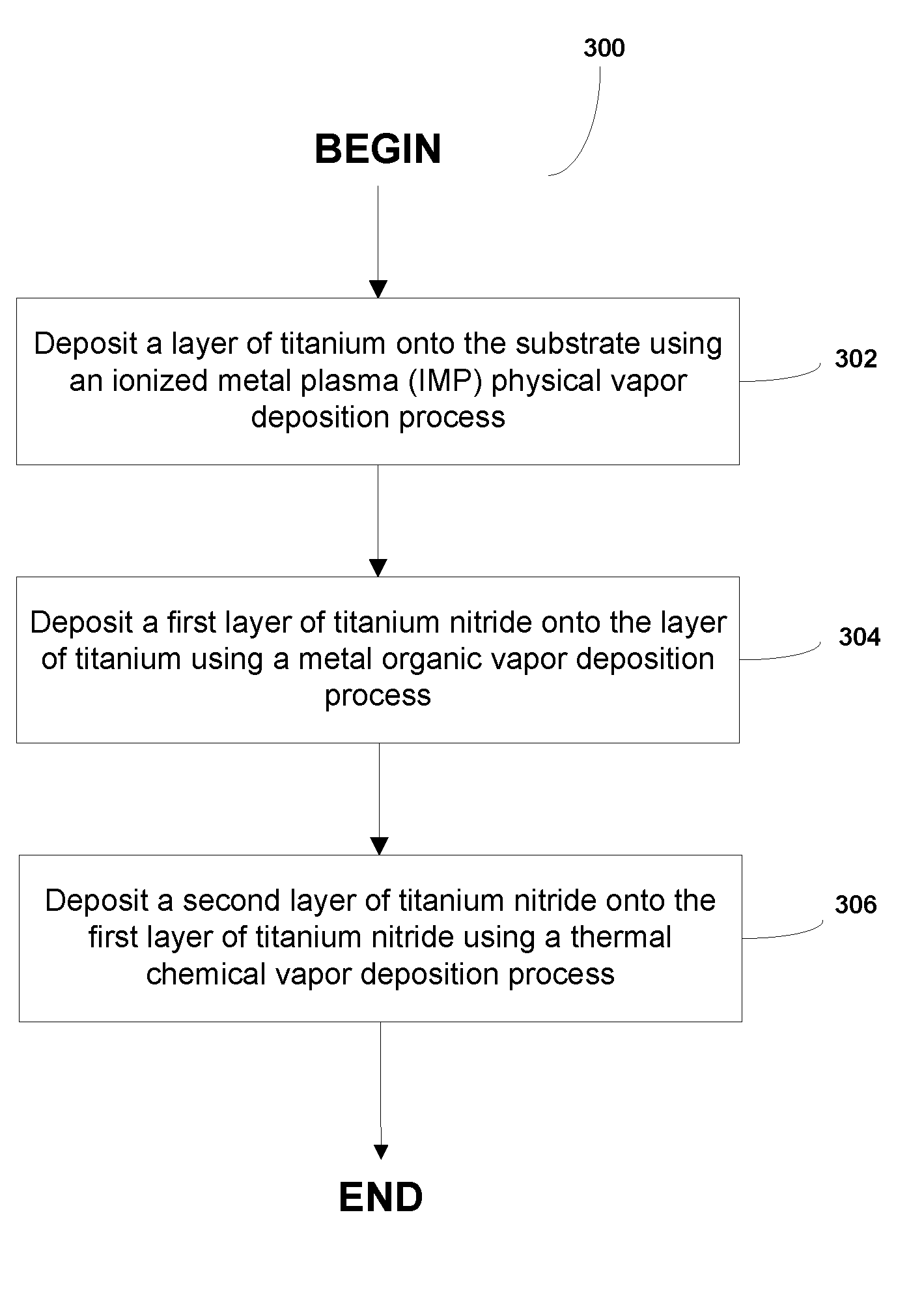

[0015]FIG. 1 is a cross-sectional illustration of the various sub-layers of material that form a barrier layer over a semiconductor substrate, in accordance with one embodiment.

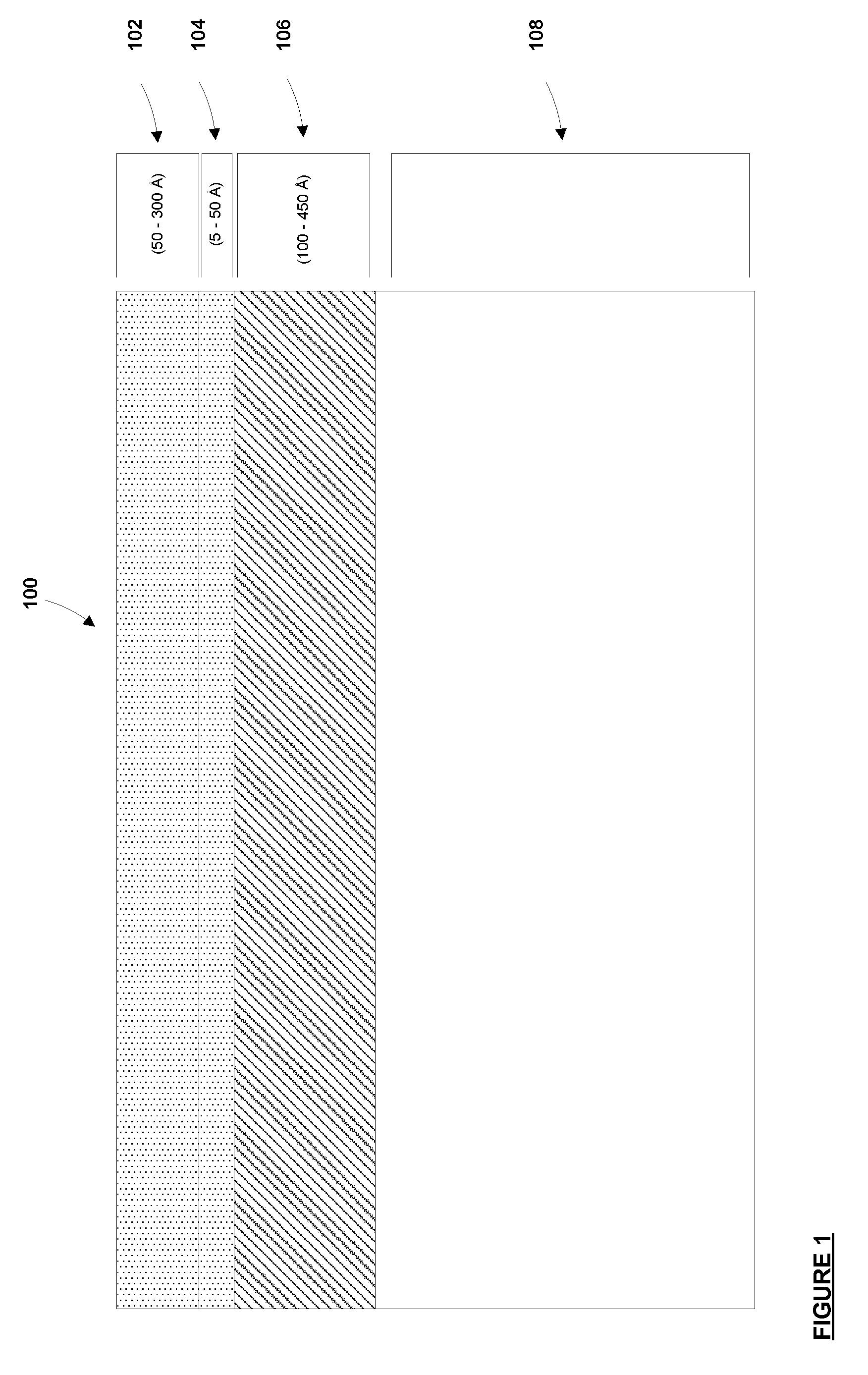

[0016]FIG. 2 is a top level illustration of a system for depositing a “mixed type” contact barrier layer onto a semiconductor substrate, in accordance with one embodiment.

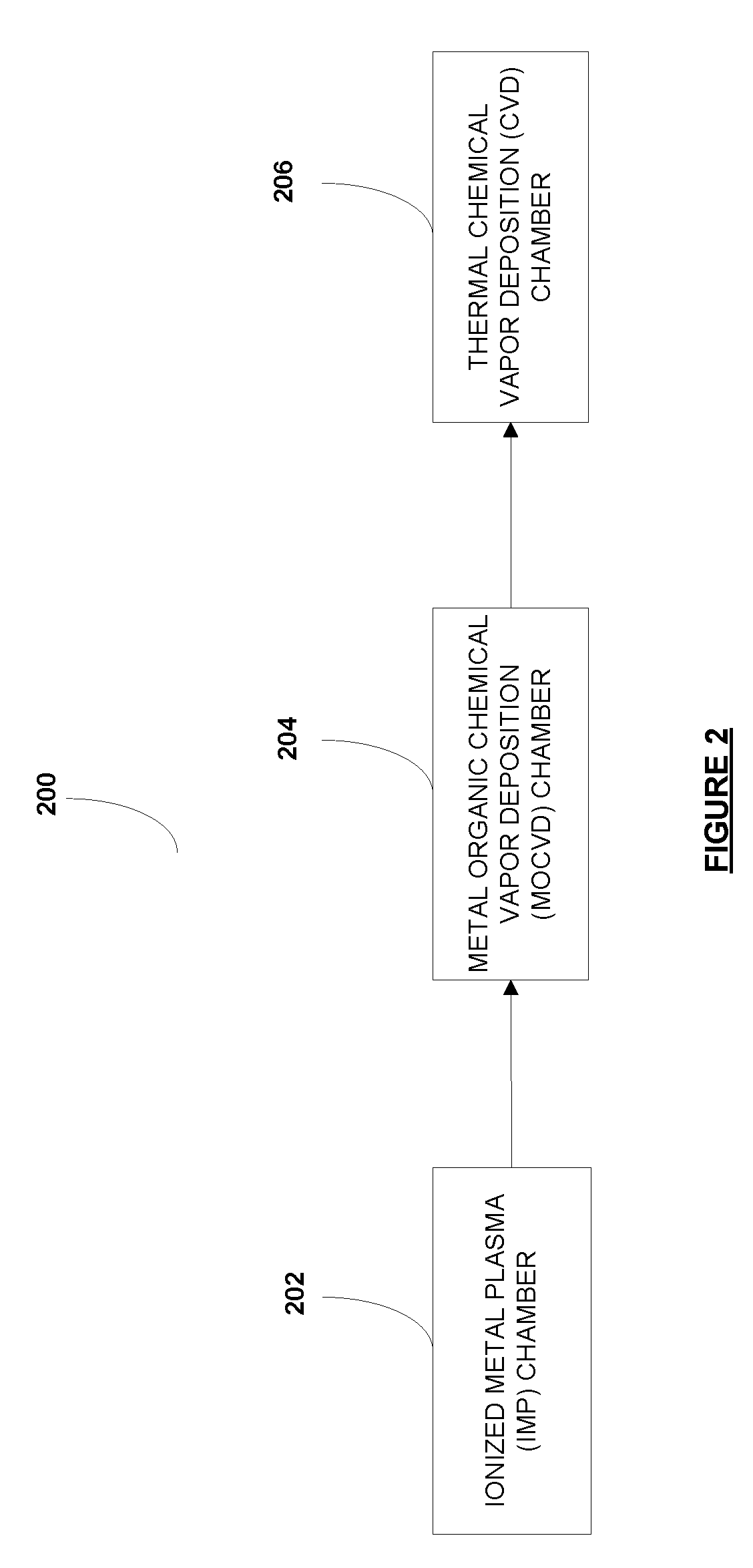

[0017]FIG. 3A is a flowchart of a method to form a new contact barrier layer onto a semiconductor substrate, in accordance with one embodiment.

[0018]FIG. 3B is a flowchart detailing the operation of the ionized metal plasma (IMP) physical vapor deposition chamber to form a layer of Ti on a semiconductor substrate, in accordance with one embodiment.

[0019]FIG. 3C is a flowchart detailing the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com