Attic Insulation with Desiccant

a technology of desiccant and attic insulation, which is applied in the field of attic insulation with desiccant, can solve the problems of increasing the cooling load, difficulty in achieving a continuous air infiltration barrier and thermal insulation barrier at the interior ceiling level, and moisture desorbed by wood attic framing materials, so as to reduce the amount of cooling energy required to cool a building and reduce the temperature of the desiccant-bearing fibrous insulating material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

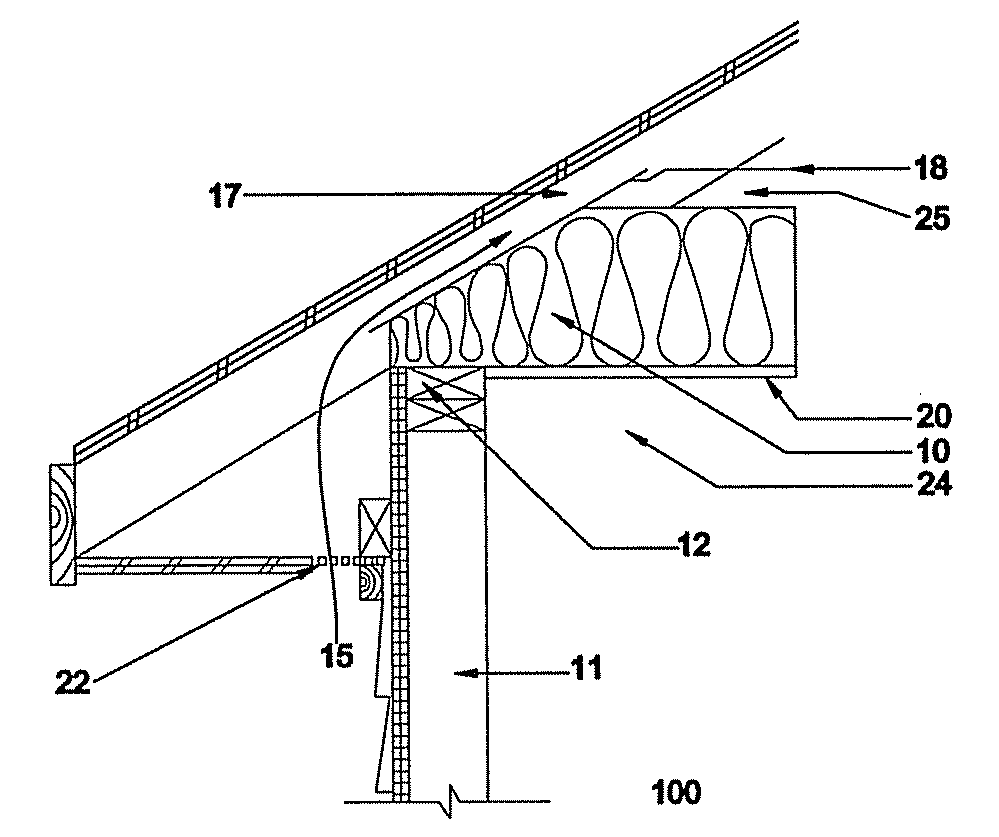

[0022]One of several alternative methods, proposed by this invention, is to change roof insulation characteristics by mixing desiccant material with a porous insulation material, such as fiber glass or cellulose insulation. In general, there are two main advantages to this process. The first is to add more thermal mass to the ceiling insulation when the desiccant adsorbs moisture which can lead to possible load shifting from peak to off-peak hours. The second is to reduce attic air moisture levels. The disadvantage with this method of adding a desiccant is that the thermal resistance of the insulation decreases somewhat due to the higher thermal conductivity of the desiccant compared to fiber glass or other insulation.

[0023]In addition to the general advantages and disadvantages of the desiccant insulation mixture mentioned above, one of the most important features of using the ceiling mixture is to add more moisture adsorption capacity. The moisture adsorption from the attic and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com