Method of Evaluating Adhesion Property, Low-Adhesion Material, and Mold for Molding Resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

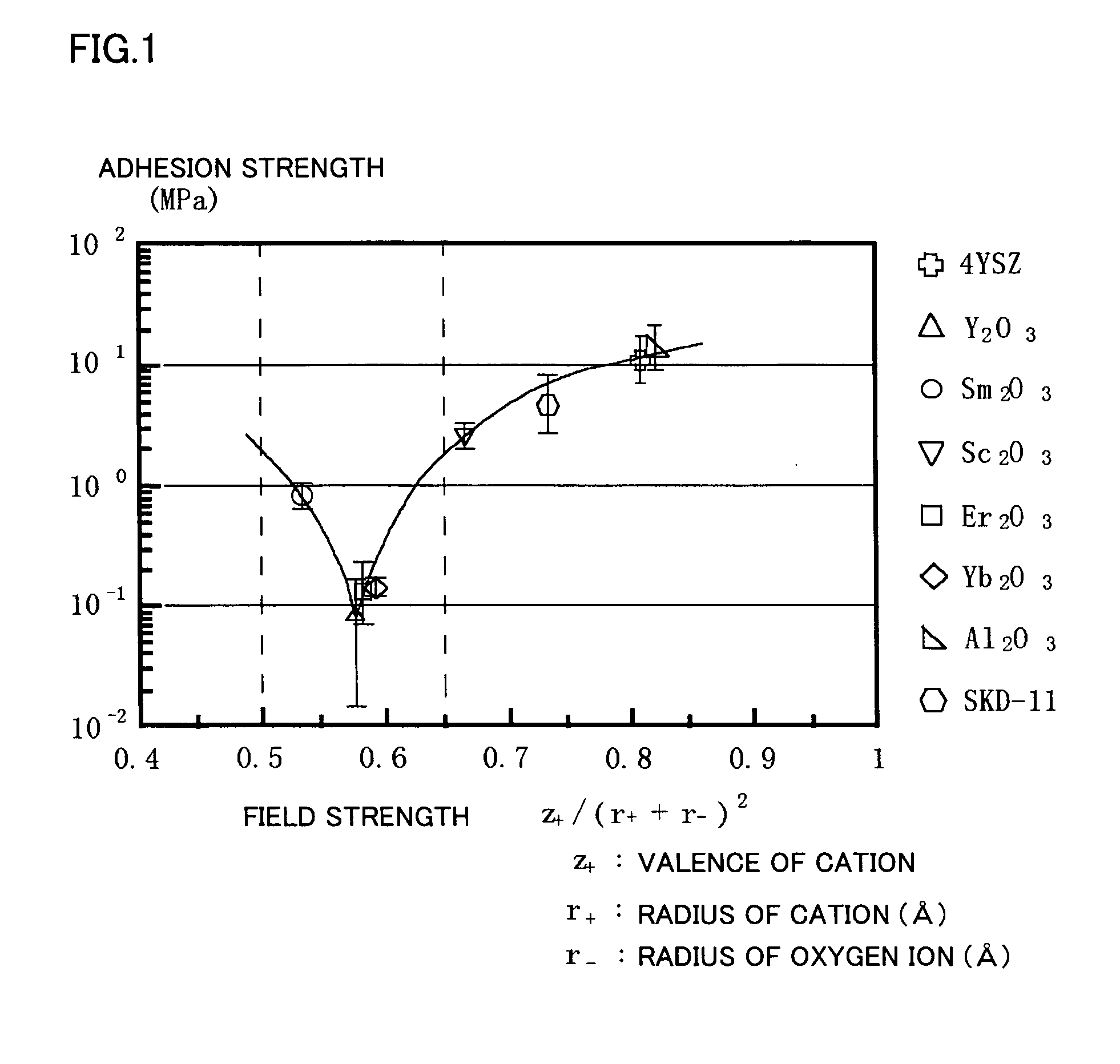

[0038]Firstly, referring to FIG. 1, explanation will be given on a method of evaluating an adhesion property between an organic substance and a surface of a member as well as a low-adhesion material in a first embodiment. FIG. 1 shows an adhesion property of a cured resin made of an organic substance. In FIG. 1, a horizontal axis represents magnitude of field strength. It is to be noted that an oxide is contained in the surface of a portion of the member to be evaluated with which a fluid resin comes into contact. The oxide contains a metal cation and an ion.

[0039]The field strength shown in FIG. 1 is a value calculated based on a valence of the metal cation and a radius of the ion. In FIG. 1, a vertical axis (logarithmic scale) represents magnitude of adhesion strength. The adhesion strength is a measured value of adhesion strength between the cured resin and the surface of the member.

[0040]The value of the field strength is calculated based on an expression z+ / (r++r·)2 as shown in...

second embodiment

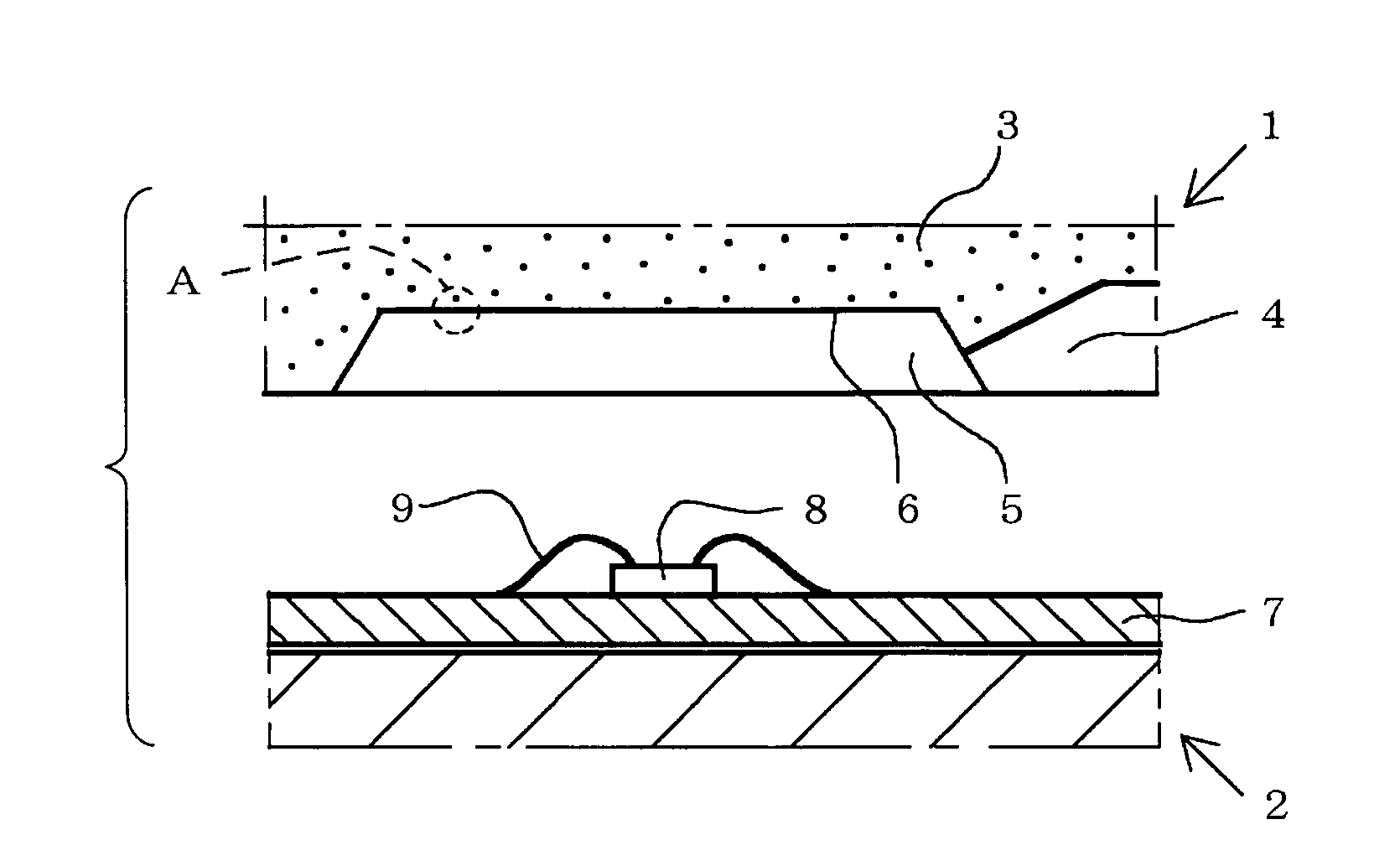

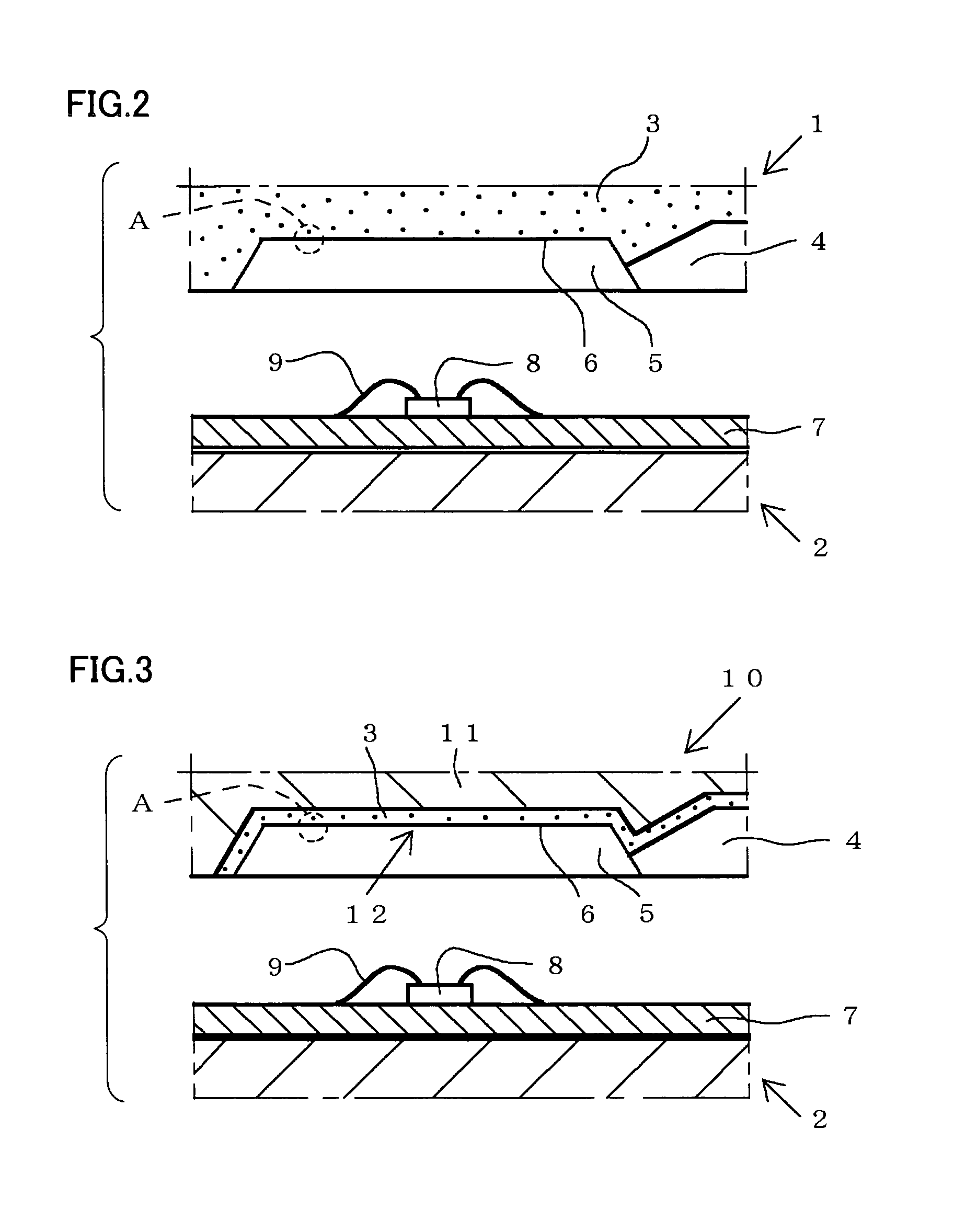

[0063]Next, referring to FIGS. 2 and 3, a mold for molding a resin in an embodiment of the present invention will be described. FIGS. 2 and 3 are cross sectional views showing a mold for molding a resin in the present embodiment and its modification, respectively, both of which are exaggerated for ease of illustration. In the present embodiment, as an example of resin molding, explanation will be given on transfer molding for sealing a chip mounted on a substrate with a resin.

[0064]In this sealing with a resin, firstly, a wired chip is accommodated in a cavity. Next, with the mold closed, the cavity is filled with a fluid resin. Thereafter, the fluid resin is cured to form a cured resin. As a result, a molded body (package) having a substrate and the cured resin is completed.

[0065]As shown in FIG. 2, the mold for molding a resin in the present embodiment includes an upper mold 1 and a lower mold 2. Upper mold 1 corresponds to the mold for molding a resin in the present invention. Up...

third embodiment

[0076]Next, referring to FIGS. 4 and 5, explanation will be given on a mold for molding a resin using a low-adhesion material of a third embodiment and its modification. FIGS. 4 and 5 are enlarged cross sectional views showing the proximity of a mold surface of a mold for molding a resin in the present embodiment and the proximity of a mold surface of a mold for molding a resin in the modification, respectively. FIGS. 4 and 5 correspond to enlarged cross sectional views of parts designated by a reference letter A in FIGS. 2 and 3, respectively.

[0077]In the mold for molding a resin in the present embodiment, material with high releasability 3 of upper mold 1 shown in FIG. 2 and of upper mold 10 shown in FIG. 3 is a porous material (a low-adhesion material 13 in FIG. 4). Further, as shown in FIG. 4, low-adhesion material 13 in the present embodiment has a base material 14 made of the low-adhesion material (oxide) described in the first embodiment, and a three-dimensional communicating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion strength | aaaaa | aaaaa |

| Valence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com