Method of Preparing Zinc Oxide Nanorods on a Substrate By Chemical Spray Pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

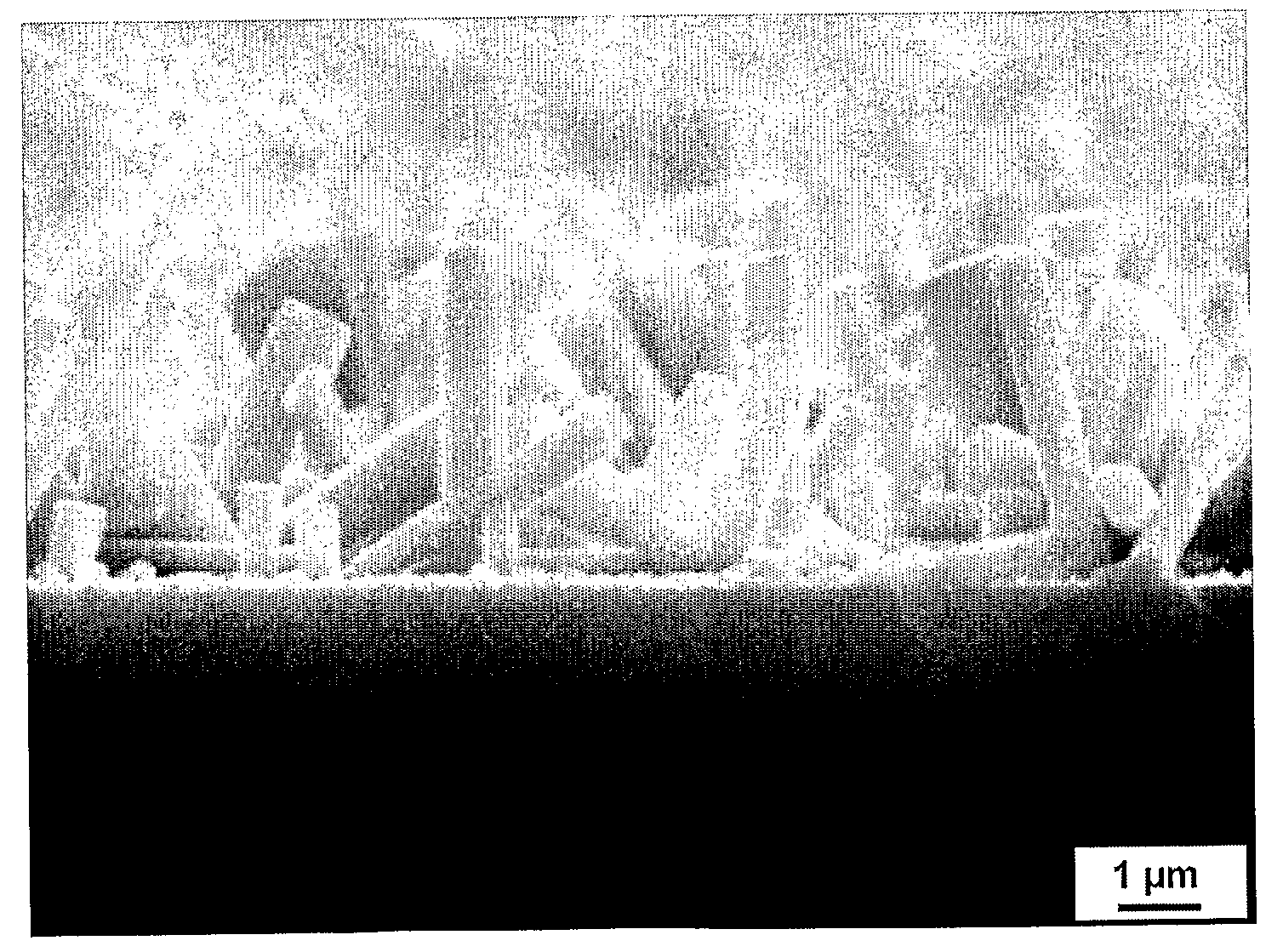

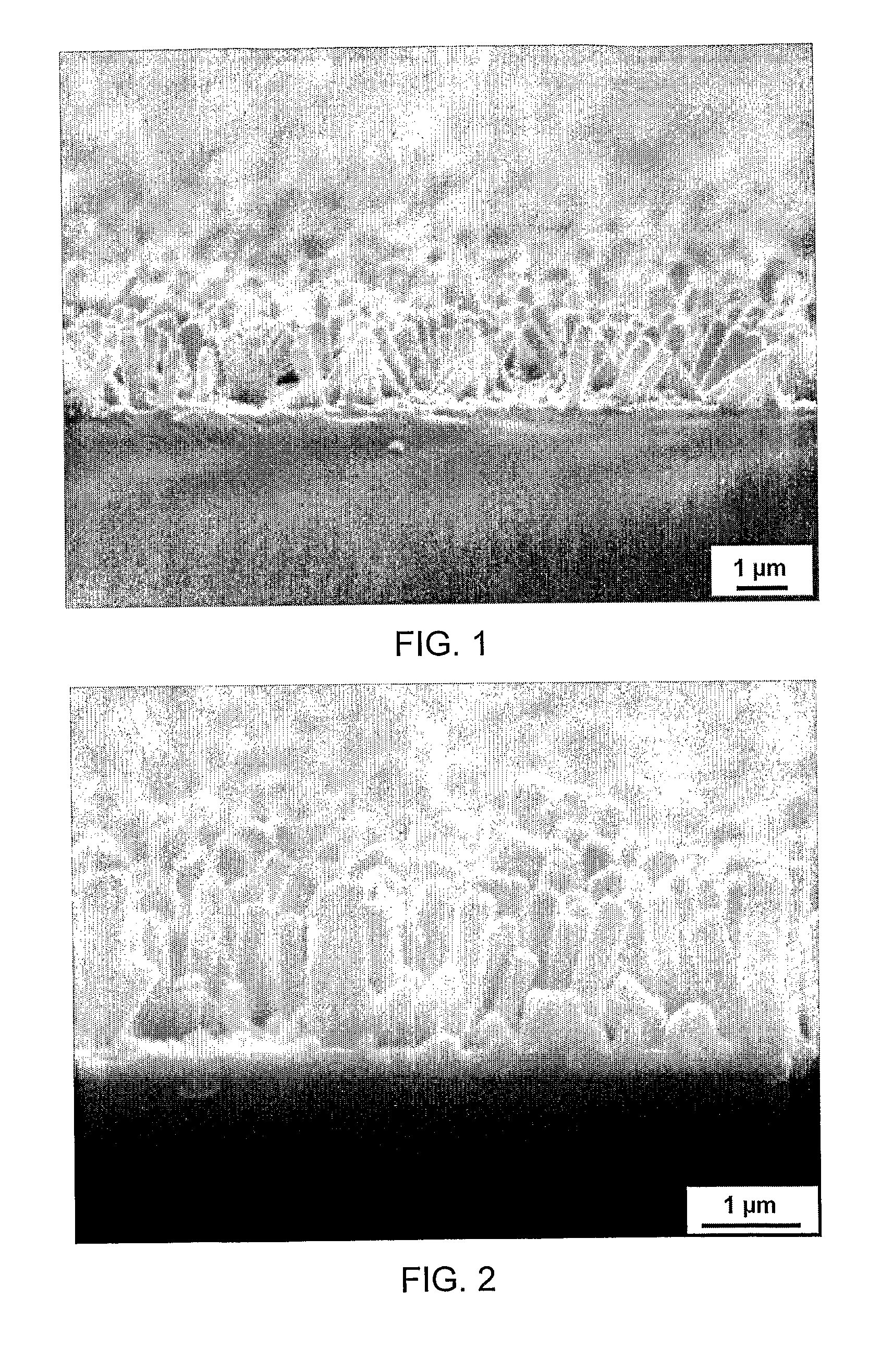

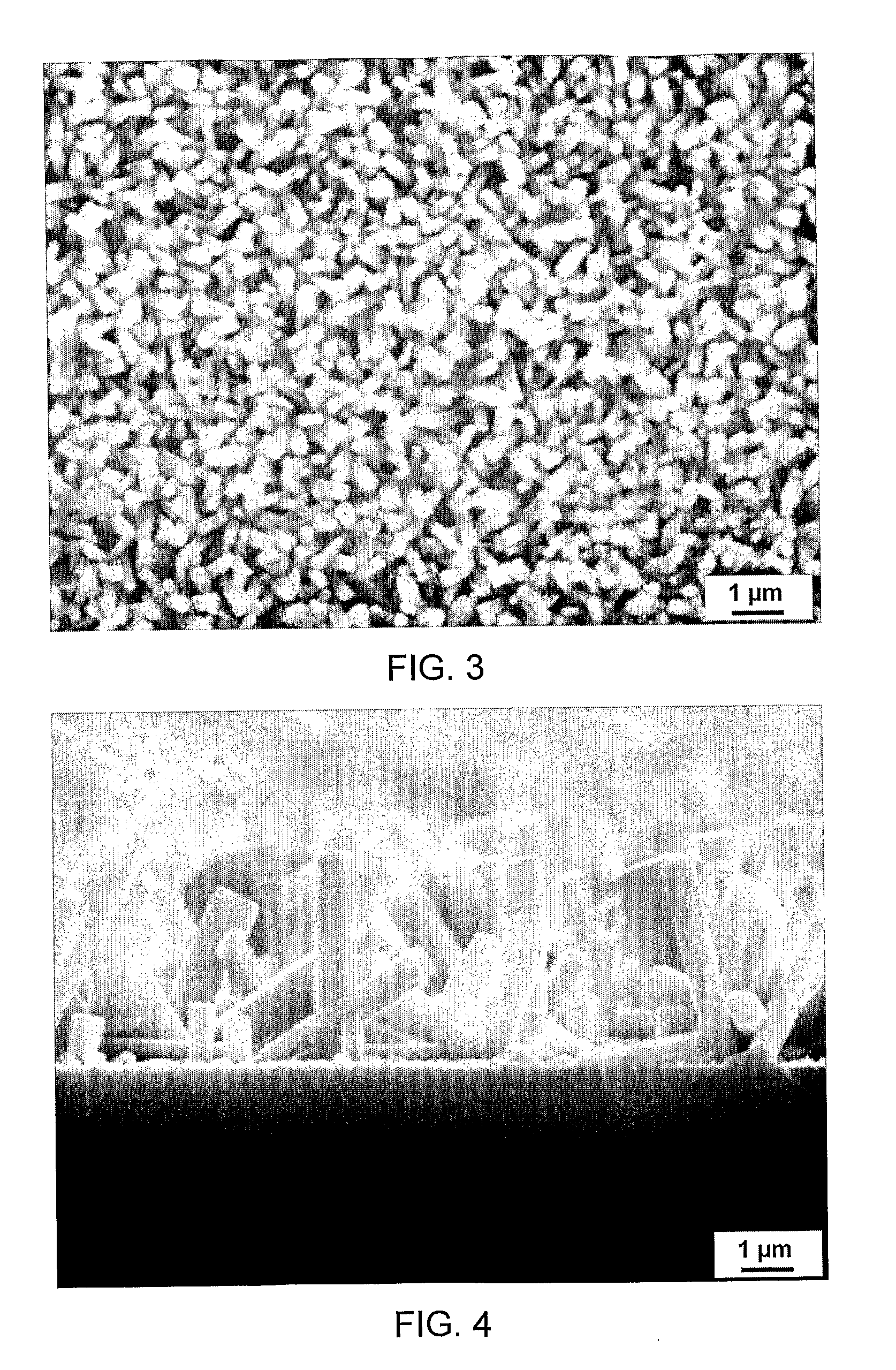

[0056]Several samples of zinc oxide nanocolumnar layers were prepared, whereas the following parameters were varied: growth temperature, stock solution composition, concentration of the precursors in stock solution, solution feeding rate, type of substrate, type of underlayers (metal oxides), and carrier gas flow rate. Samples were studied by the techniques of X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and photoluminescence (PL). The results are shown in FIGS. 1 to 19.

[0057]The solutions were prepared at the room temperature (from about 18 to about 25° C.), but generally, the temperature of the solution is not critical.

[0058]Zinc chloride (pro analysis, Merck) or zinc acetate dihydrate (pro analysis, Merck), thiourea (pro synthesis, Merck), Urea (pro synthesis, Merck), 2-propanol (pro analysis, Merck), Ethanol (pro analysis, Merck), deionized water (with specific resistance 18 MΩ.cm) were used as starting materials.

[0059]A so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com