Tailgate and ramp for pickup truck

a tailgate and pickup truck technology, applied in the field of tailgates for pickup trucks, can solve the problems of tailgates bouncing around during transportation, items are just a little too long to fit in the cargo bay and close the tailgate, and are not generally desired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]While this invention is susceptible of embodiment in many different forms, the drawings show and the specification describes in detail a preferred embodiment of the invention. It should be understood that the drawings and specification are to be considered an exemplification of the principles of the invention. They are not intended to limit the broad aspects of the invention to the embodiment illustrated.

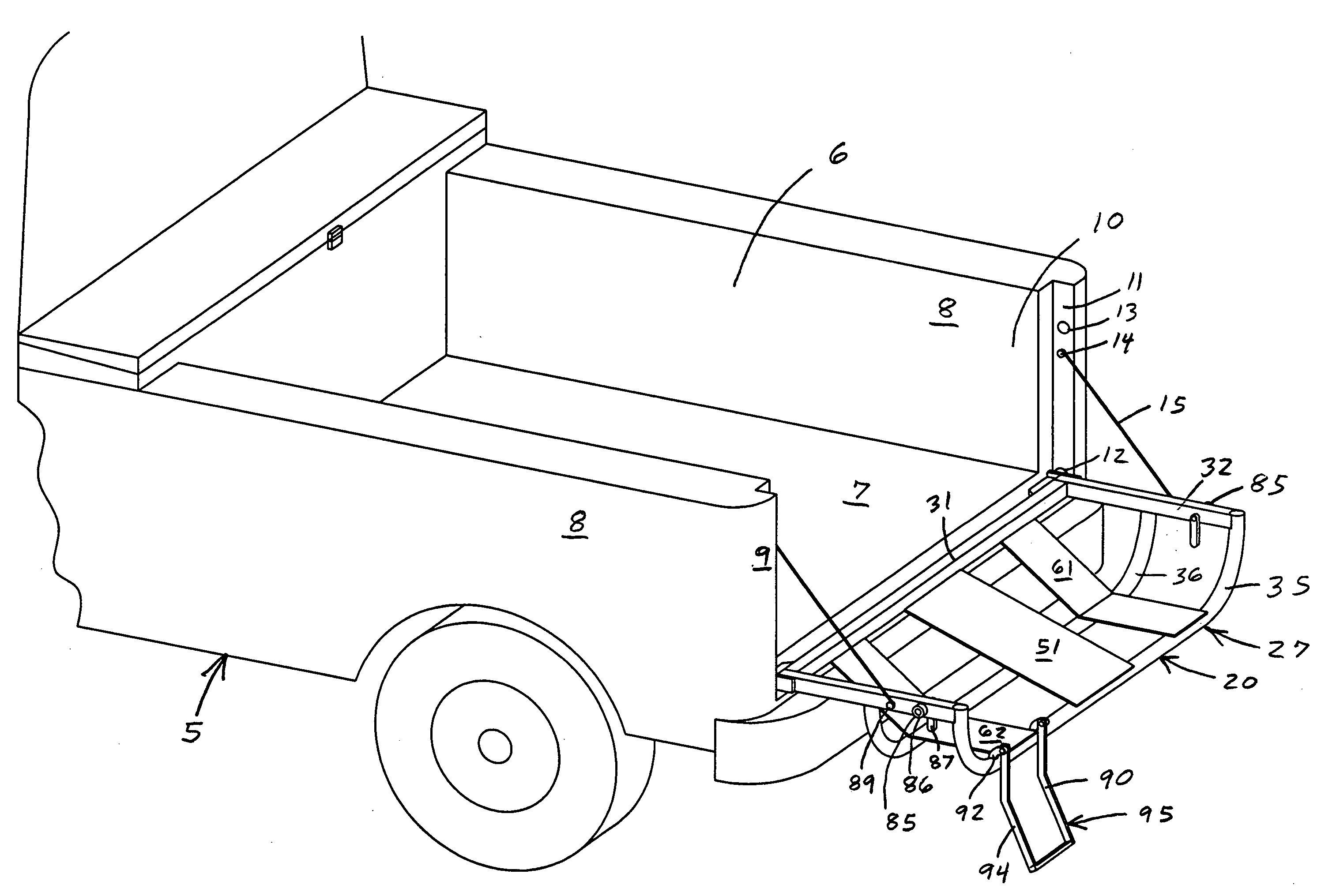

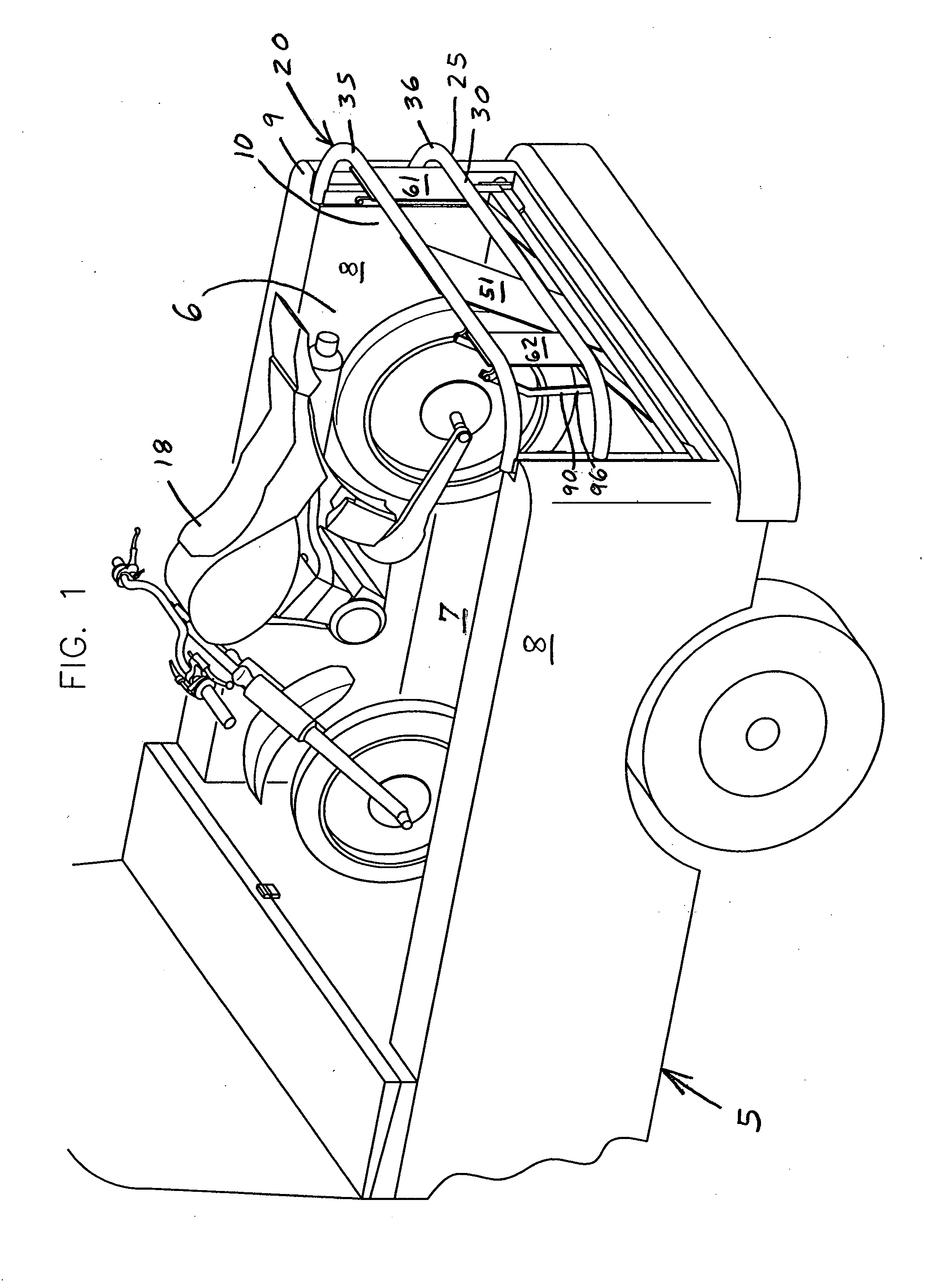

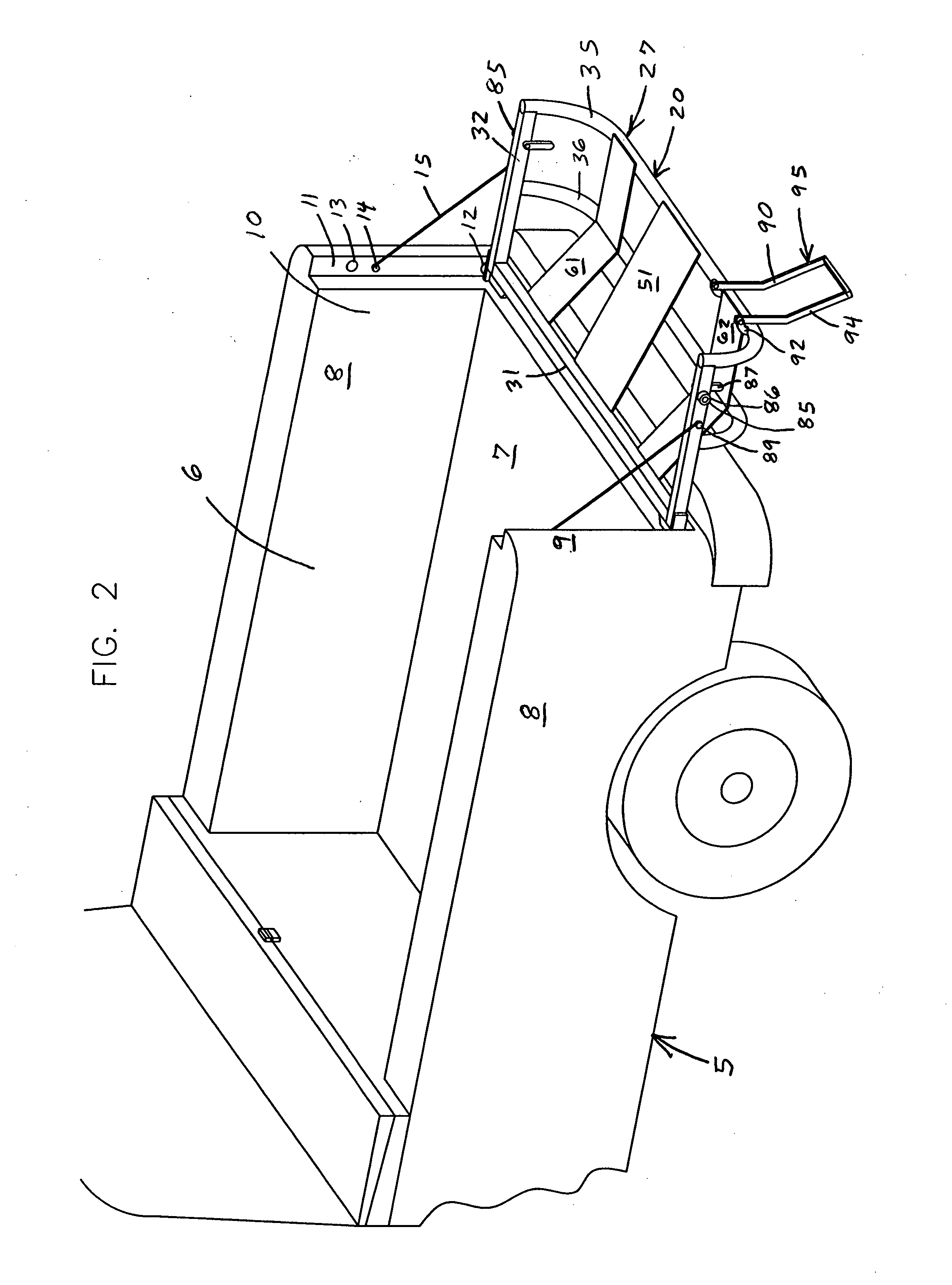

[0028]Pickup trucks 5 have a cargo bay 6 defined by the rear wall of the cab, the truck bed 7, and the sidewalls 8 of the truck bed as in FIGS. 1 and 2. The rear end 9 of the truck 5 has a generally rectangular tailgate opening 10 for loading items into and out of the cargo bay 6. The width of the opening 10 is defined by the sidewalls 8 of the truck 5, and is generally about 60 inches wide. The height of the opening 10 is defined by the planar surface of the truck bed 7 and the top of the sidewalls 8, and is generally about 20 inches tall. When originally manufactured, a pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com