Display device and manufacturing method thereof

a technology a manufacturing method, which is applied in the direction of semiconductor devices, instruments, electrical appliances, etc., can solve the problems of increasing the cost, reducing the yield, and requiring a more complicated process, so as to prevent the mobility of a thin film transistor from decreasing, the deposition rate of a microcrystalline semiconductor film can be increased, and the mass productivity of a display device can be increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment modes

[0047]Hereinafter, embodiment modes of the present invention are described with reference to the drawings. It is easily understood by those skilled in the art that the modes and details disclosed herein can be modified in various ways without departing from the spirit and scope of the present invention. Therefore, the present invention should not be interpreted as being limited to the description of the embodiment modes to be given below.

embodiment mode 1

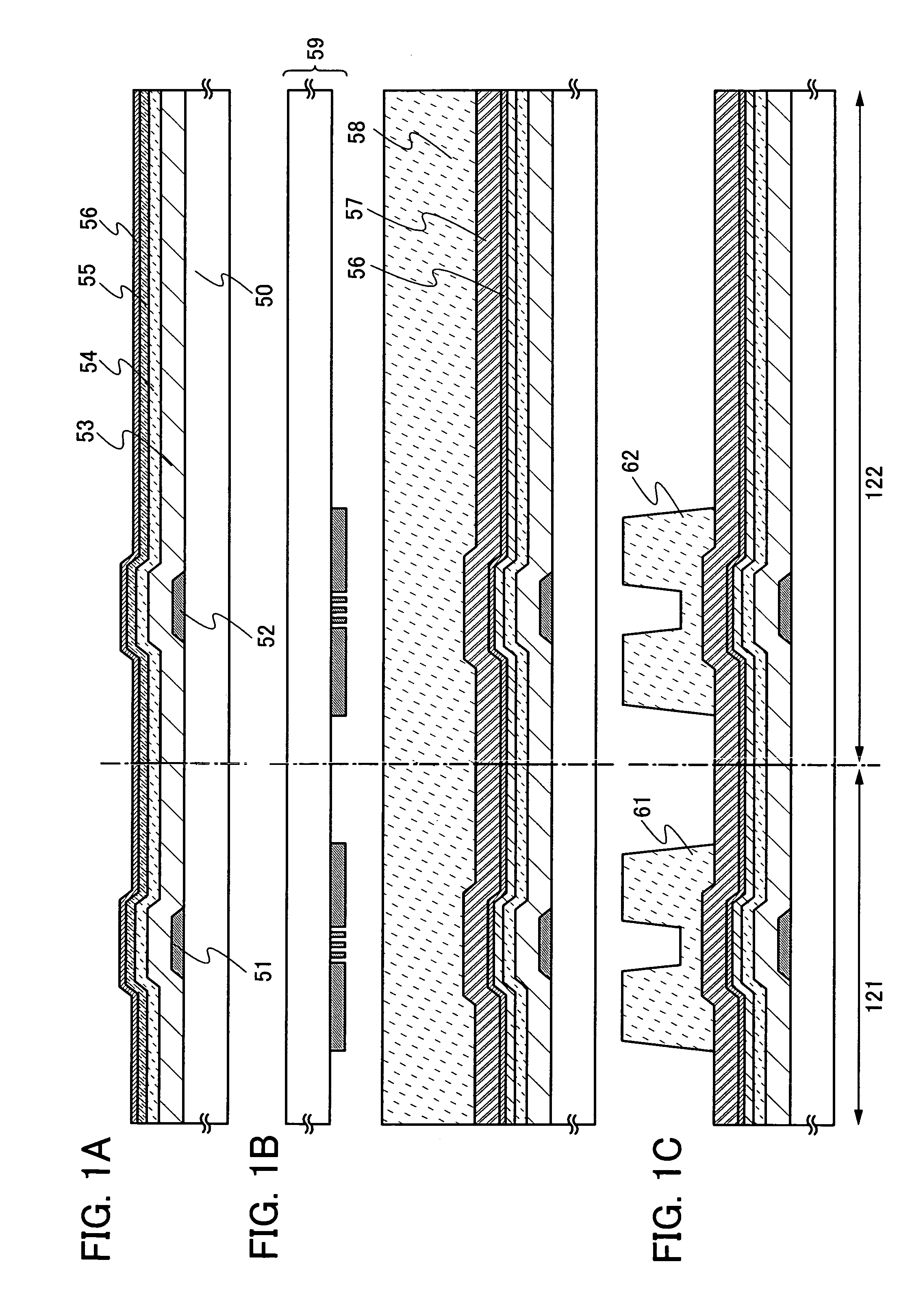

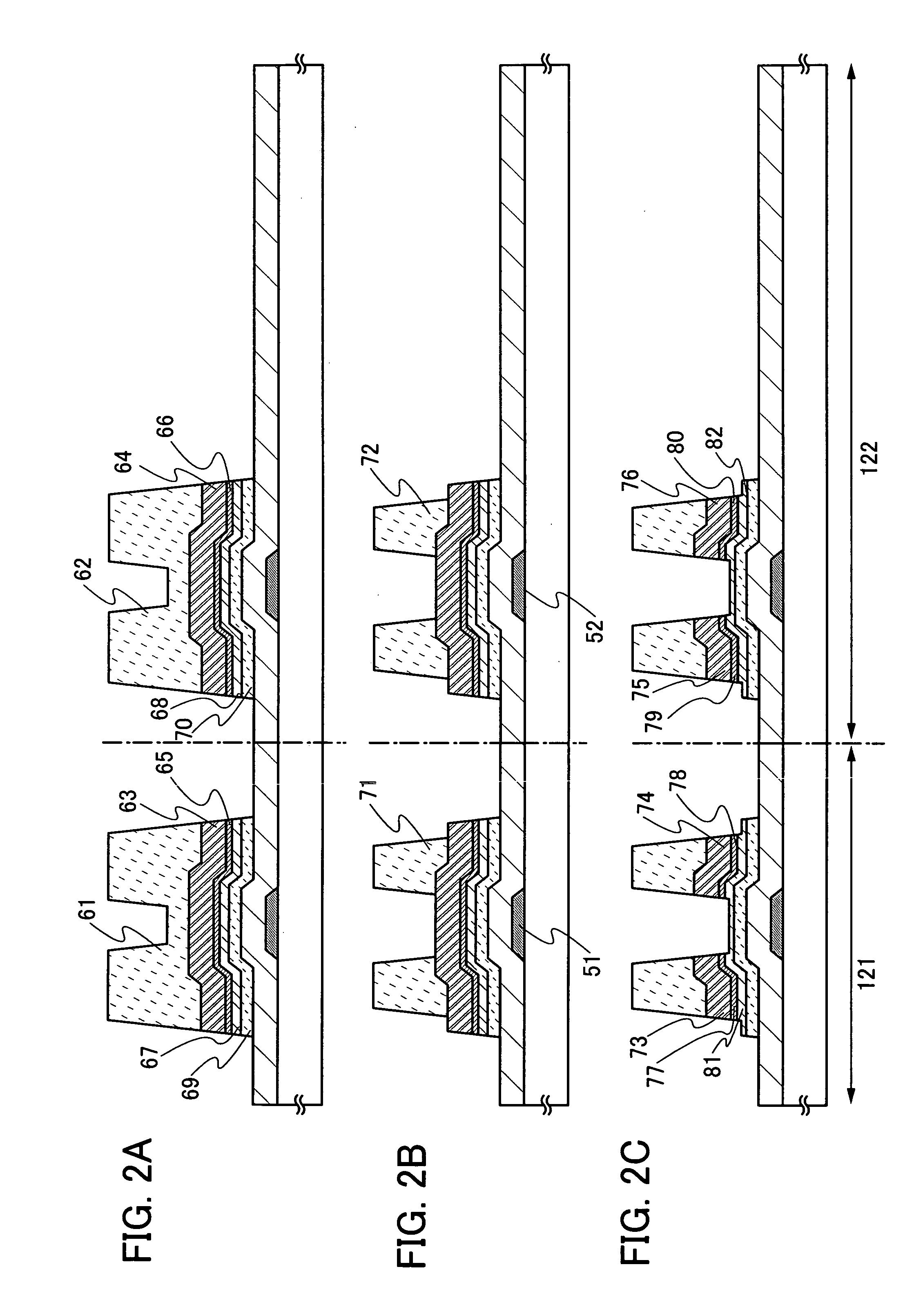

[0048]A method for manufacturing a display device of the present invention is described. First, the description is made using a liquid crystal device, which is one mode of the display device. FIGS. 1A to 3B are cross-sectional views illustrating a thin film transistor used for a driver circuit and a thin film transistor used for a pixel portion. With regard to a thin film transistor including a microcrystalline semiconductor film, an n-channel thin film transistor has higher mobility than a p-channel thin film transistor; thus, an n-channel thin film transistor is more suitable for a driver circuit. However, in the present invention, either an n-channel or p-channel thin film transistor can be used. With any polarity of a thin film transistor, it is preferable that all the thin film transistors formed over one substrate have the same polarity so that the number of manufacturing steps is reduced.

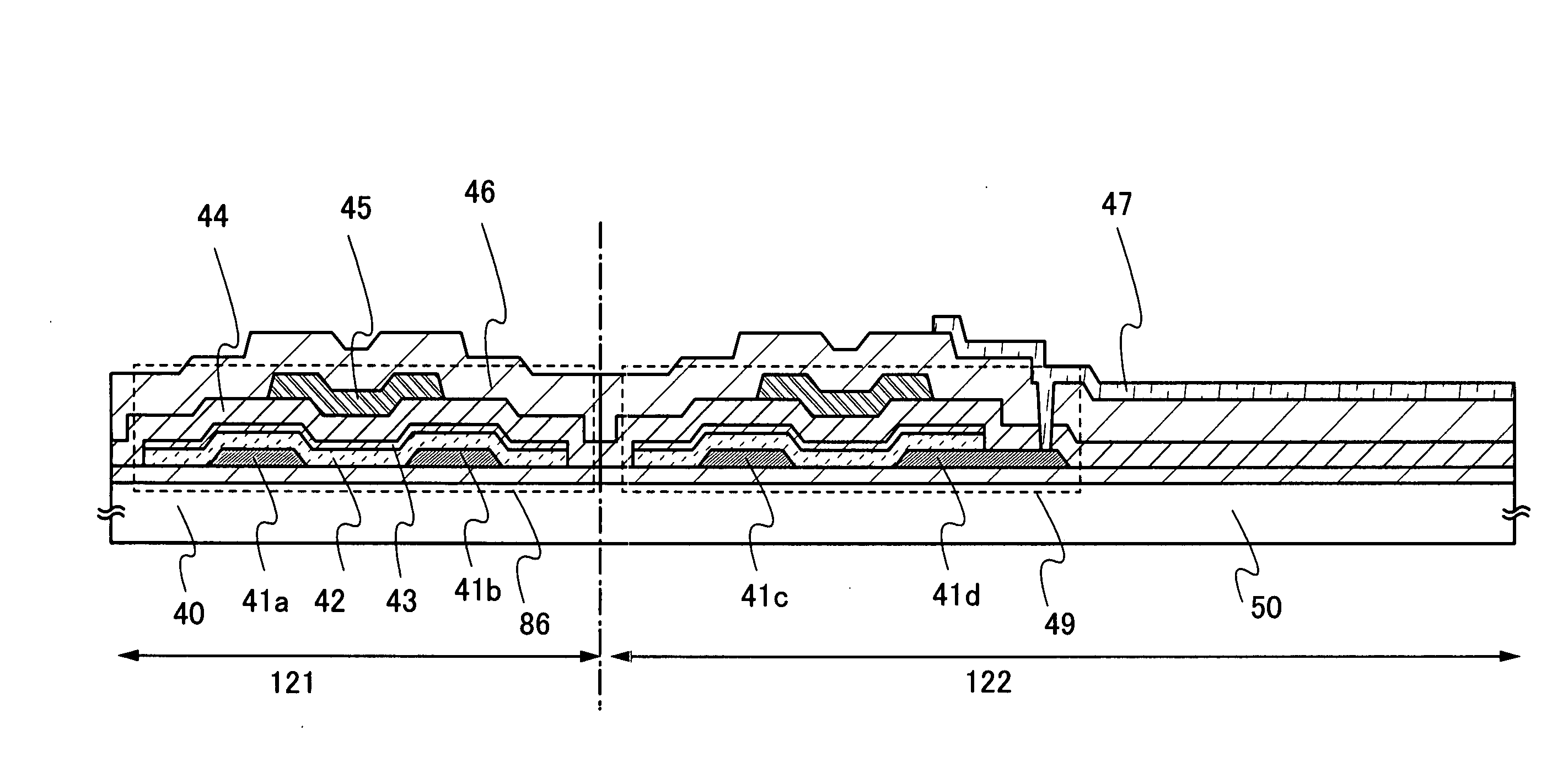

[0049]As illustrated in FIG. 1A, gate electrodes 51 and 52 are formed over a substrate 50...

embodiment mode 2

[0192]This embodiment mode describes a structure of a display panel, which is one mode of the display device of the present invention.

[0193]FIG. 15A illustrates a mode of a display panel in which a pixel portion 6012 formed over a substrate 6011 is connected to a signal line driver circuit 6013 that is formed separately. The pixel portion 6012 and a scanning line driver circuit 6014 are each formed using a thin film transistor including a microcrystalline semiconductor film. By forming the signal line driver circuit with a thin film transistor by which higher mobility can be obtained compared to the thin film transistor including the microcrystalline semiconductor film, operation of the signal line driver circuit, which demands a higher driving frequency than that of the scanning line driver circuit, can be stabilized. The signal line driver circuit 6013 may be formed using a thin film transistor including a single-crystalline semiconductor, a thin film transistor including a polycr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com