Fresh water flushing system for boat engines

a technology for flushing systems and boats, which is applied in the direction of steam power plants, motor-driven power plants, vessel construction, etc., can solve the problems of shortening the affecting the service life of the engine, and still having to somehow dissipate the heat generated by the friction of the moving parts, etc., and achieves the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

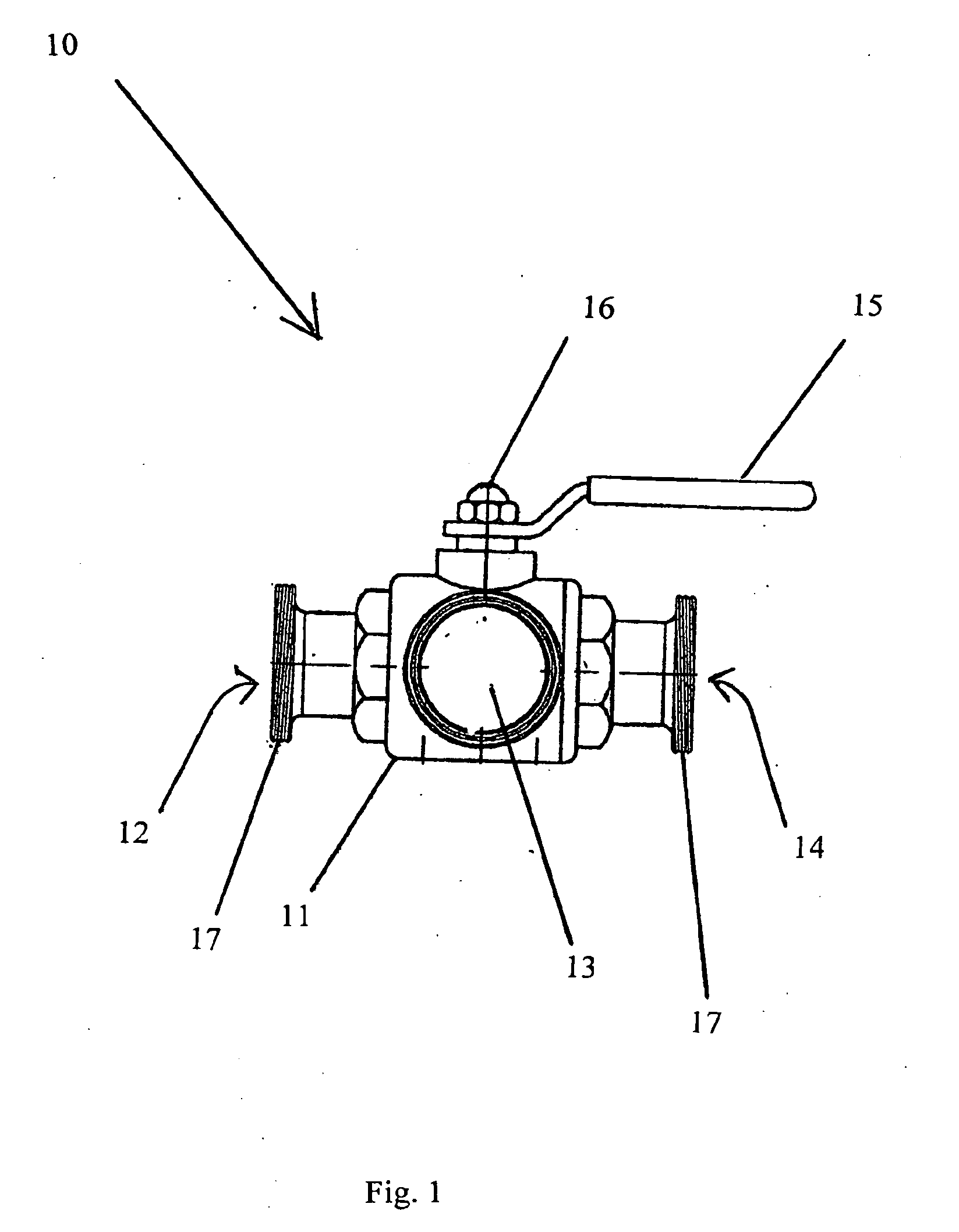

[0040]The valve 10 has a main body 11. Main body 11 has a first opening 12, a second opening 13, and a third opening 14. Each of openings 12, 13, and 14 may be constructed and arranged with any acceptable fitting including, but not limited to screw threads 17, a barbed fitting 18 or a pipe adapter 20. Valve 11 may have three different fittings or may have a combination of fittings as desired. Valve 10 has a handle 15 secured in place with locking nut 16. Handle 15 is secured to valve stem 30 with locking nut 16. Movement of handle 16 rotates T-ball valve 36 and controls the desired path of water through valve 10. Valve stem 30 is circumferally surrounded by packing flange 31. Below flange 31 are, in order, Teflon washer 32, Teflon packing 33, and t-ball connector 34. T-ball connector 34 is surrounded by Teflon ball seals 35.

[0041]Valve 10 has, on main body 11, three end connectors 37 that lead to each of openings 12, 13, and 14. Each end connector 37 has a silicon O-ring 38, union n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com