Method and apparatus for a product dispenser with increased insulative properties

a product dispenser and insulative property technology, applied in the field of product dispensers, can solve the problems of losing sales, not always providing an equivalent thermal solution, and product dispenser manufacturers no longer being able to utilize foam blowing agents, etc., and achieve the effect of increasing insulative properties and increasing thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

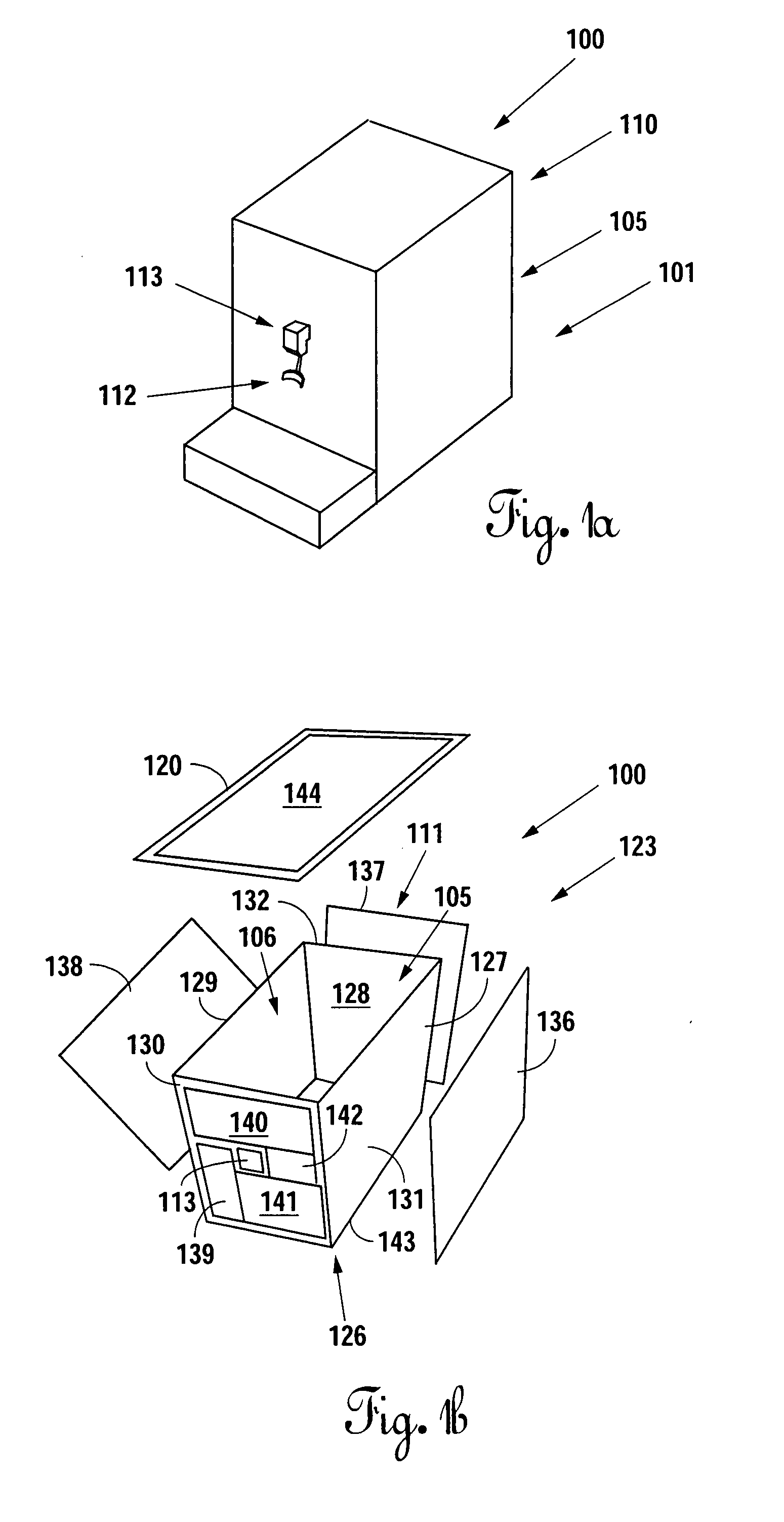

[0034]In a simplest form, a product dispenser 100 includes a housing 110, and at least one product flow circuit 101 for receiving a product and dispensing the product. The housing 110 includes a vessel 105 supported by a frame assembly. The frame assembly provides structural support to the components of the product dispenser 100, and may be constructed from virtually any form of structural member made from commonly available structural materials, including steel, aluminum, plastics, and the like. In this first embodiment, the frame assembly is a welded steel frame.

[0035]The vessel 105 may be any form of product containment device, including tanks, bins, liners, and the like, that includes or forms a chamber 106. The vessel 105 may be constructed from virtually any form of material that is structurally adequate to contain and support a chamber 106 full of a particular product. In this first embodiment, the vessel 105 is a liner formed from polypropylene. At a minimum, the vessel 105 ...

second embodiment

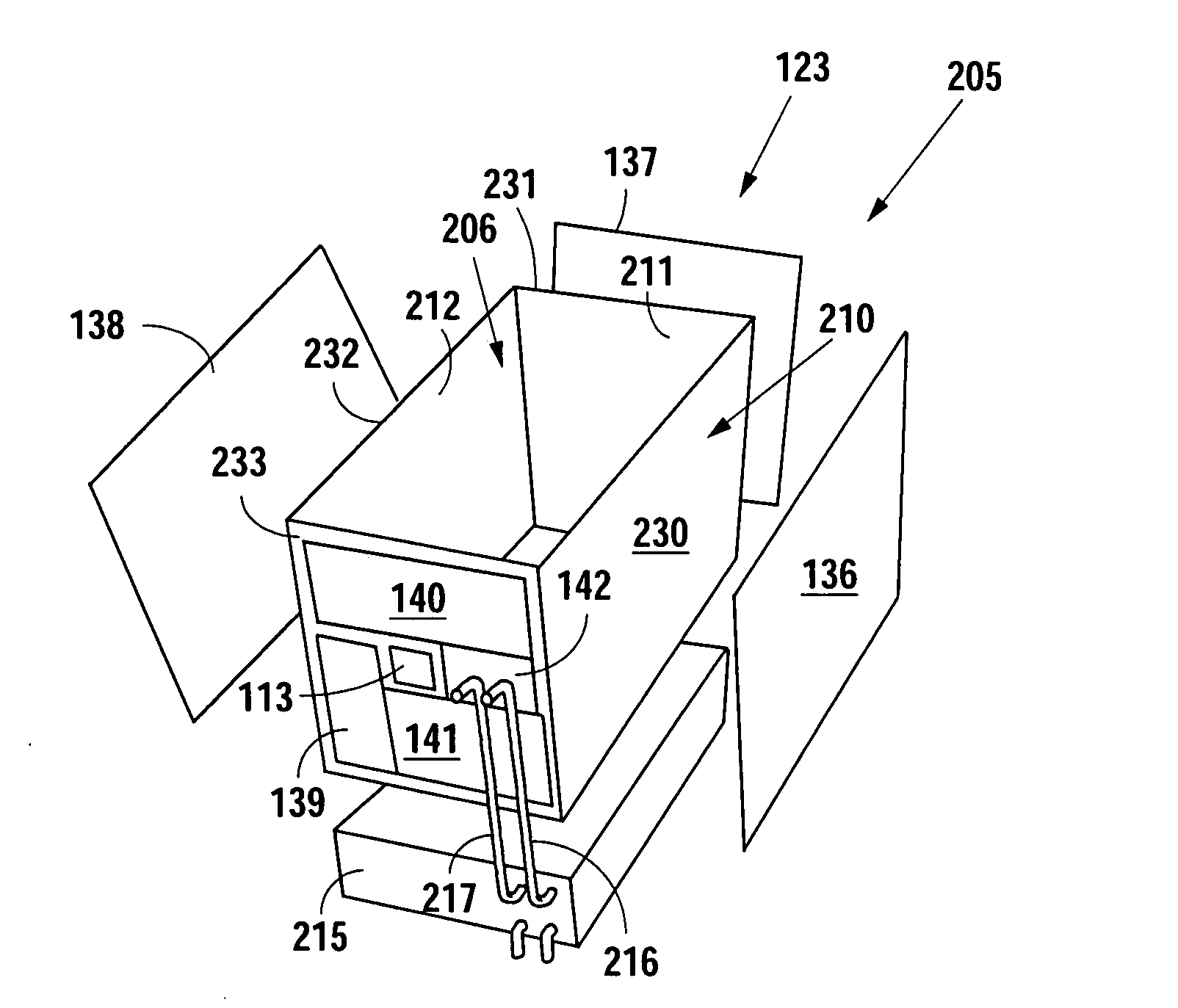

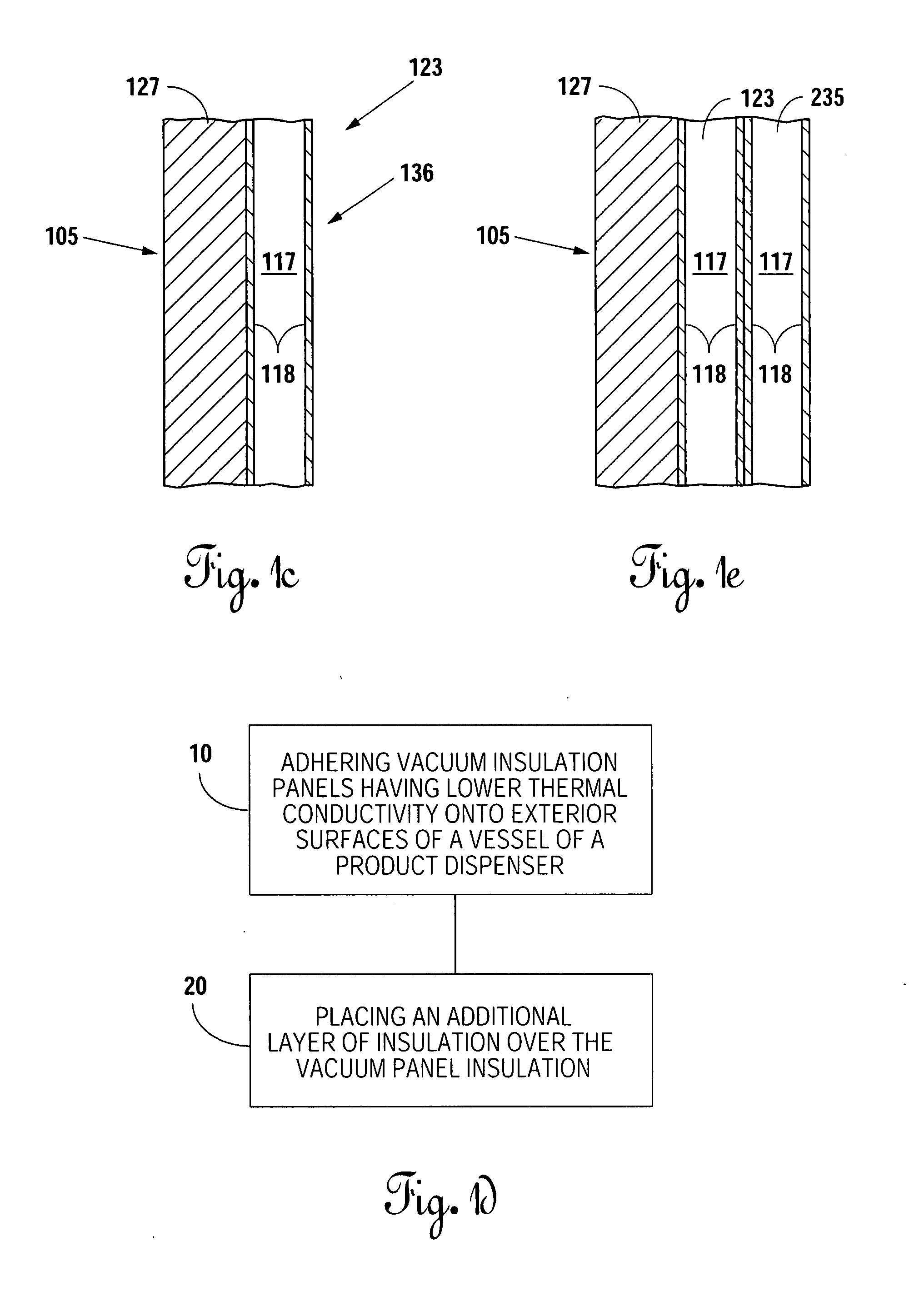

[0056]In an extension of the second embodiment, the product dispenser 200 may further include a second layer of insulation 235 disposed over the first layer of vacuum insulation panels. The second layer of insulation 235 may be a second layer of vacuum insulation panels, or may be a layer of as-formed foam insulation 151. As shown in FIG. 3c, an as-formed foam insulation 151 is identical to that of the product dispenser 150. The as-formed foam insulation 151 permanently locates and supports any product lines disposed around the vessel 205, and creates a composite insulation platform, identical to that shown in FIG. 2b. The increased thermal properties provide an increased thermal efficiency for the chamber 206.

third embodiment

[0057]In a third embodiment, a product dispenser 250 includes a concentrate flow circuit 252, and a diluent flow circuit 253. The product dispenser 250 further includes a vessel 260 having a first wall 271, a second wall 272, a third wall 272, a fourth wall 274, and a floor panel 275 that form a chamber 261. The concentrate flow circuit 252 is connectable to a concentrate source, and includes at least one concentrate line 255. The diluent flow circuit 253 is similarly connectable to a diluent source, and includes at least one diluent line 256. At least one diluent line 256 and one concentrate line 255 pass through the chamber 261 of the vessel 260. The diluent line 256 and the concentrate line 255 may make multiple passes through the chamber 261 to provide adequate length for desired amount of heat transfer. The opposing ends of the diluent line 256 and the concentrate line 255 are then connectable to a product valve for dispensing.

[0058]The product dispenser 250 further includes a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com