Acoustic bandgap structures adapted to suppress parasitic resonances in tunable ferroelectric capacitors and method of operation and fabrication therefore

a technology of ferroelectric capacitors and band gaps, applied in the direction of fixed capacitors, variable capacitors, fixed capacitor details, etc., can solve the problems of reducing the quality factor of tunable ferroelectric capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

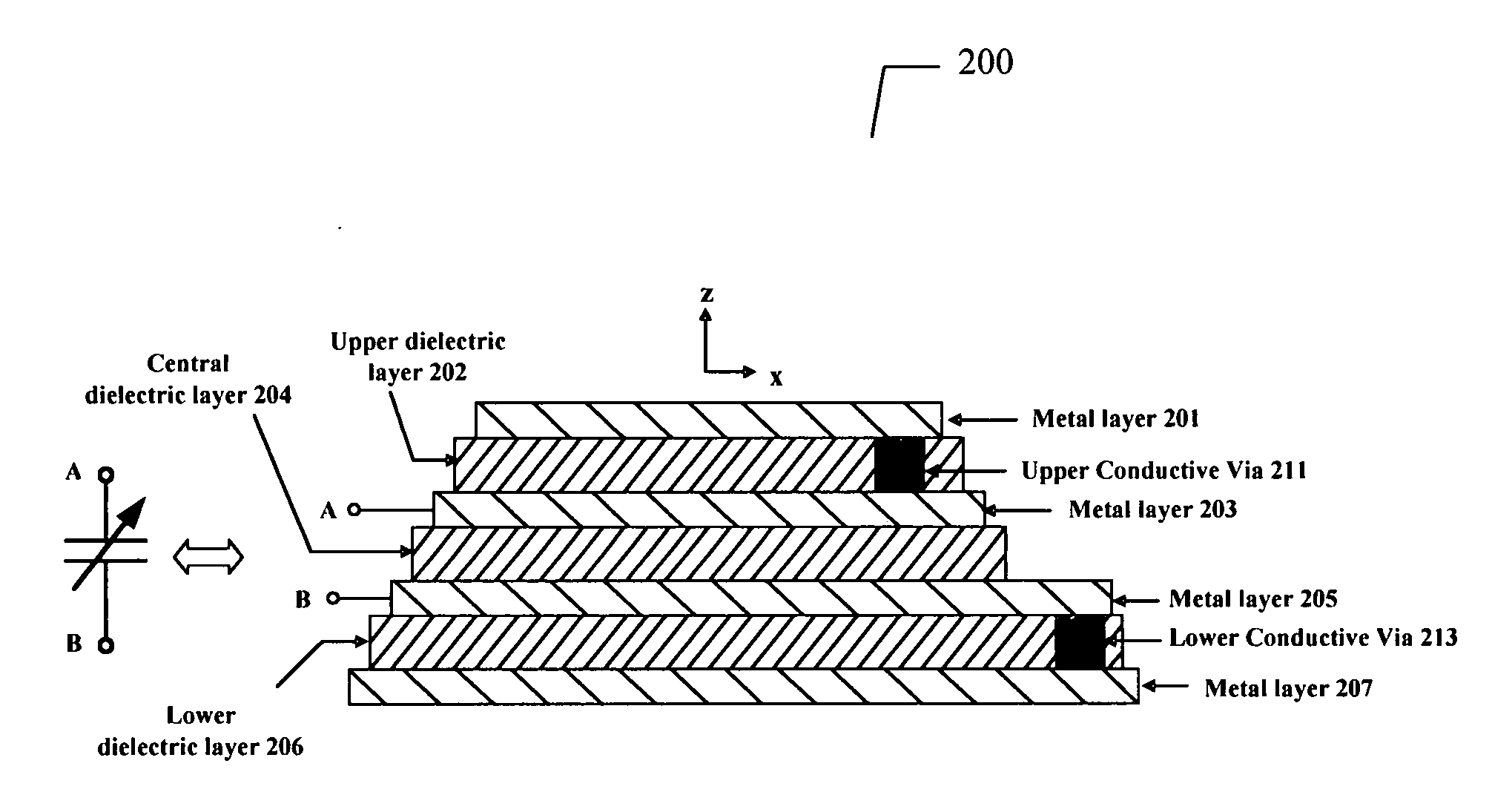

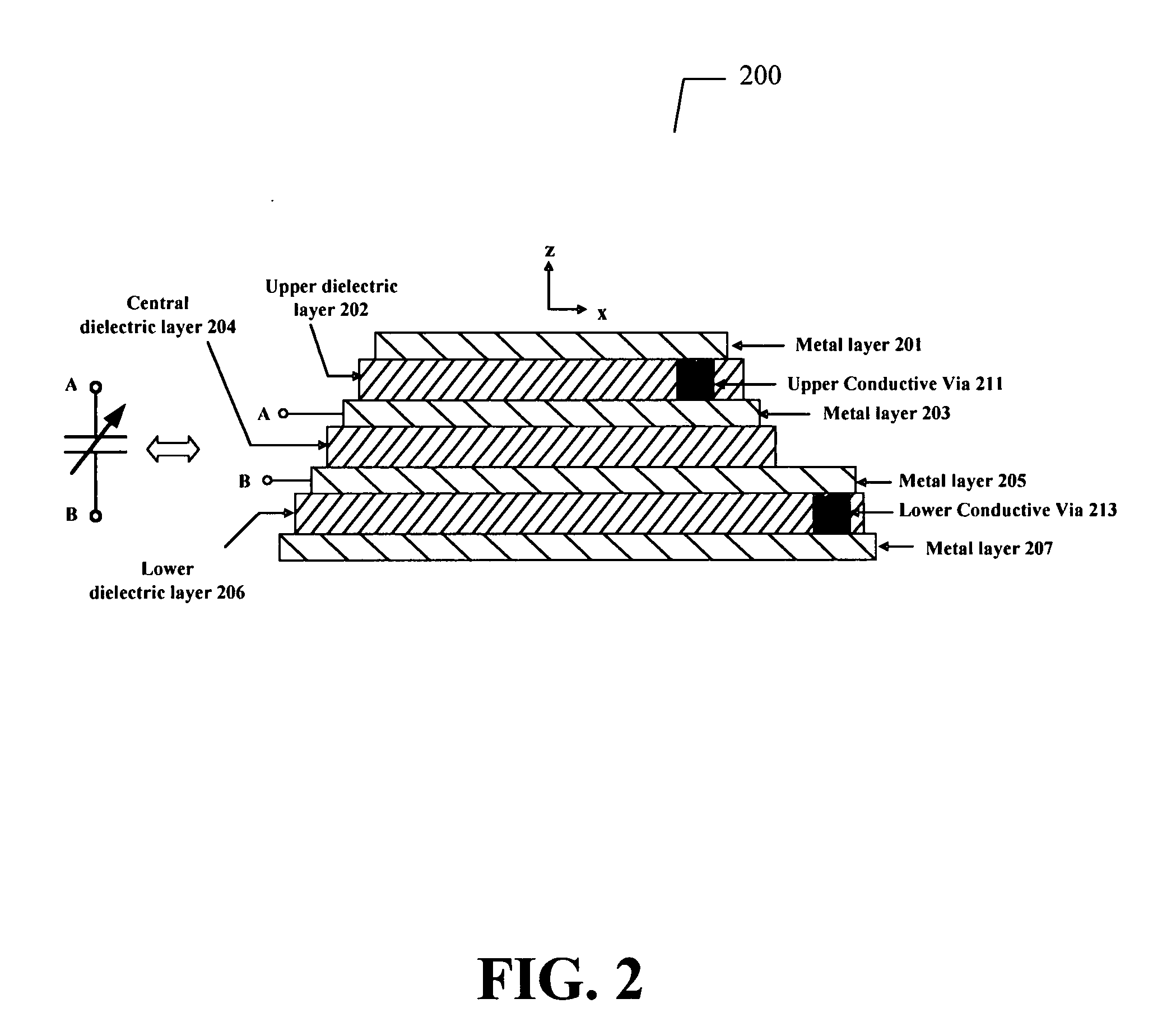

[0034]Turning now to FIG. 2 at 200 is the present invention. This is a thin film tunable capacitor fabricated as a layered structure in the z direction. Dielectric layers 202, 204, and 206 are stacked ferroelectric layers of essentially the same acoustic characteristic impedance and the same thickness. The ferroelectric material may be BaSrTi, BaSrTiO, SrTiO, or any other voltage dependent dielectric film. These dielectric layers are sandwiched between conductive electrode layers which are described in FIG. 2 as metal layers 201, 203, 205, and 207. These metal layers have essentially the same acoustic characteristic impedance and the same thickness. Typically these metal layers would be identical materials, but not necessarily and the present invention is not limited to this. Given these restrictions, the structure of FIG. 2 is a 1D periodic acoustic structure.

[0035]Furthermore, metal layers 201 and 203 may be electrically shorted together by a conductive via 211. Metal layers 205 a...

second embodiment

[0037]the present invention is an extension of stacked tunable capacitors where the middle electrode (metal layer 305) is biased at a DC voltage and the top and bottom electrodes (metal layers 303 and 307) are held at ground voltage. This biasing scheme ensures that the biasing electric fields in dielectric regions 304 and 306 are antipodal, or counter-directed. When so biased, the superimposed RF fields will launch acoustic waves from dielectric layers 304 and 306 that essentially cancel each other at a certain frequency associate with the lowest acoustic resonance of the structure. However, certain higher order acoustic modes will not cancel and this is the reason for the ABG structure.

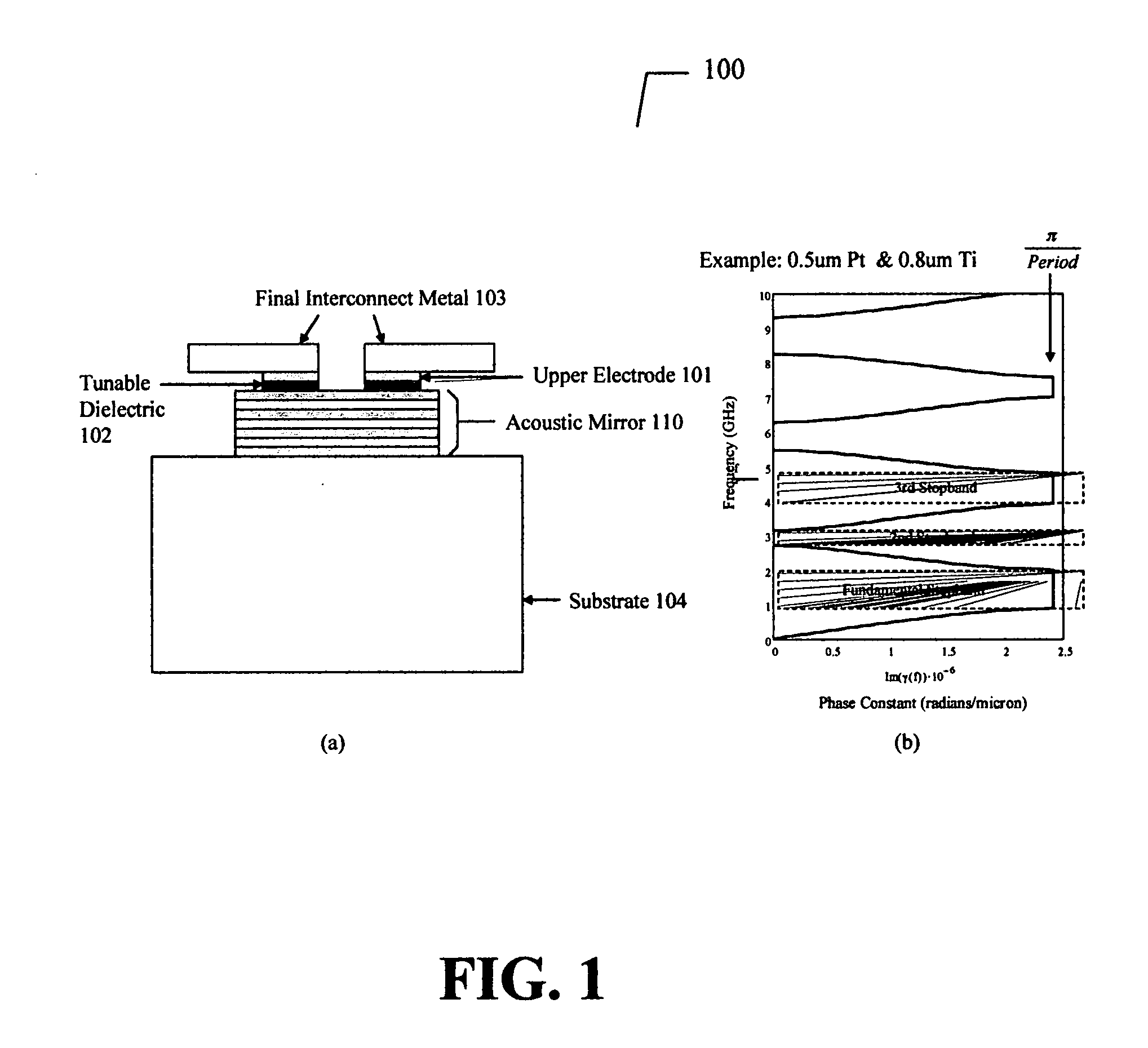

[0038]To predict the acoustic bandgaps (ABGs) that may be realized from the aforementioned embodiments, one may approximate the stack with an equivalent transmission line model of an infinite periodic structure. A unit cell is identified and its ABCD parameters are calculated. Given parameters A and...

embodiment b

[0057 shown in FIG. 3 may also be modeled using Mason's model for the acoustically active layers. One such model, shown in FIG. 18 generally as 1800, allows the calculation of electrical impedance and Q. Note that the secondary of the two transformers is wired differently to produce opposite phases of longitudinal movement in the dielectric layers 304 and 306. This is needed because, in FIG. 3, the DC biasing electric fields are oppositely directed across layers 304 and 306. Also in this model is the assumption that the capacitor structure is suspended in air. However, mounting this structure solidly to a substrate will not affect the electrical performance (Zin or Q) in any significant way within the ABG frequency range since the ABG is defined by the tunable dielectric layers and its near neighbors.

[0058]Note that the acoustic circuit models shown herein may use simple transmission lines for the acoustically inert layers. Alternatively, such layers may be modeled using passive T-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com