Bioactive composition for cosmetic applications

a technology of bioactive compositions and cosmetic raw materials, applied in the direction of biocide, plant ingredients, plant growth regulators, etc., can solve the problems of inconvenient process preparation of cosmetic raw materials, insignificant, unacceptable coloring of creams or lotions, etc., and achieve the effect of reducing the number of metal complexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0138]The preparation of a distilled Curcuma longa extract by thin-film distillation is described below.

[0139]1 kg of dried, comminuted rhizome of Curcuma longa was extracted continuously with CO2 for 4 h at 300 bar and 40° C. to exhaustion. The crude extract was obtained through expansion of the CO2 / extract mixture to ambient pressure into a cold-trap. The extraction was repeated several times, with yields of about 45-50 g of extract being obtained per kg of dry rhizome. The extract was an intensely orange-colored oil with a Gardner color number of 11.3 which had a characteristic odor.

[0140]200 g of the extract were distilled over a thin-film evaporator with external heating surface at a temperature of 100° C. and a pressure of 10−2 mbar. 162 g of a yellowish, clear liquid (Gardner color number 3.5) were obtained as distillate, and 33 g of a dark, cloudy oil were obtained as residue. The distilled extract was used for the formulation and effectiveness experiments described below (E...

example 2

[0141]The following example illustrates the connection between distillation yield and color of the distilled extract. The procedure was analogous to that in Example 1, except the temperature of the vaporization surface was varied in the range from 90 to 110° C. The results are shown in the table below:

Vaporization temperature / ° C.:90100110Distillation yield / %:697437Color number (Gardner):3.23.43.7

example 3

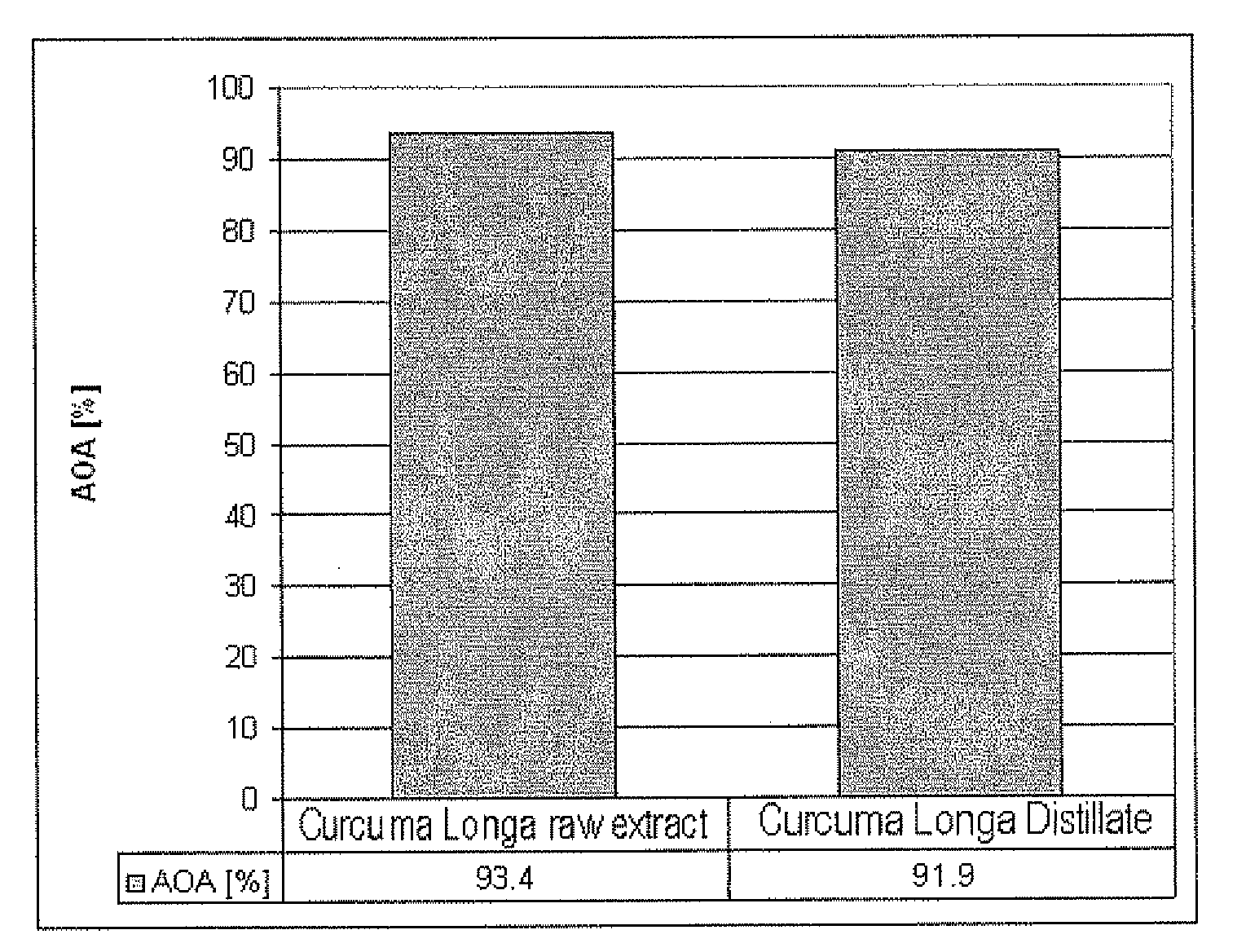

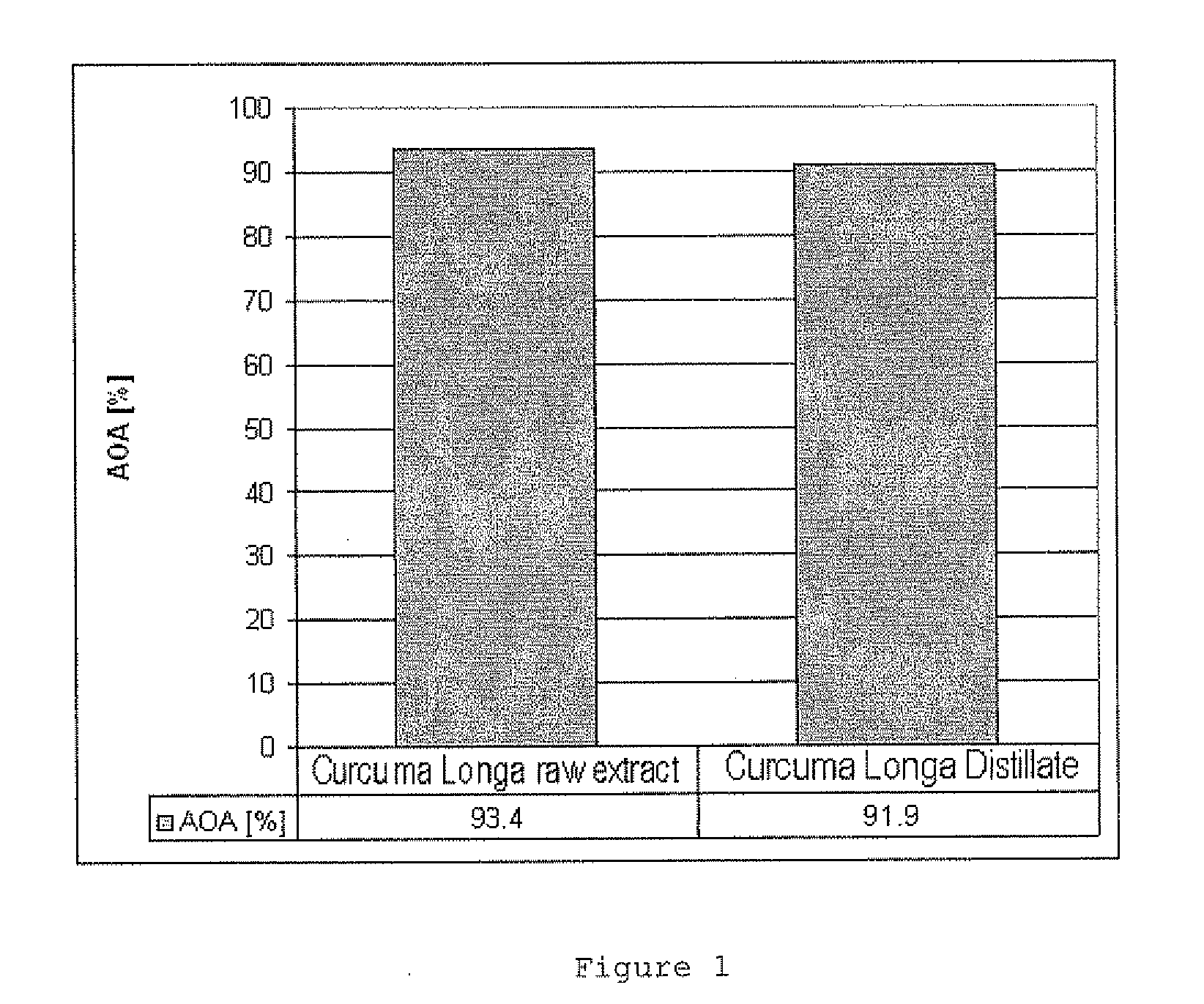

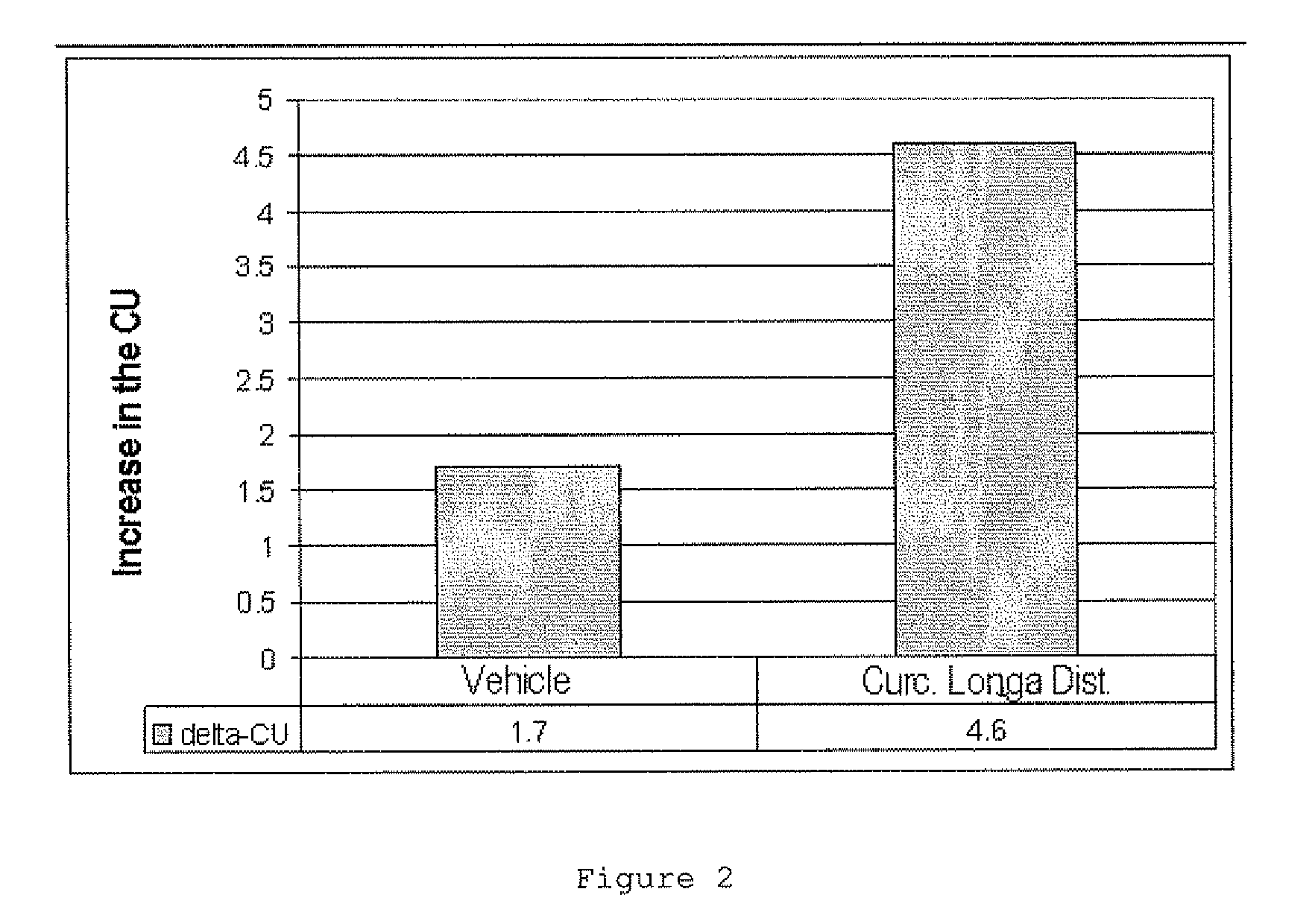

[0142]The influence of the addition of Curcuma longa crude extract and of the distilled extract according to the invention to cosmetic formulations on the color is shown below.

[0143]Various cosmetic formulations with the crude extract and with the distillate were prepared. Furthermore, the blank formulation without extract was prepared. The color of these formulations was determined. For this, the CIE-Lab color space was used as a basis. By stating the L*a*b* values it is possible to determine a color precisely. The axes in the Lab space correspond directly to perceptible properties of the colors. The red(+a) / green(−a) values are spread along the “a” axis, and the yellow(+b) / blue(−b) values are on the “b” axis (cf. DIN 6174).

F1. O / W Lotion with 0.5% Curcuma Longa Extract

F1-AF1-BF1-CDecyl oleate5.7%5.7%5.7%Ethylhexyl stearate6.5%6.5%6.5%Glyceryl stearate0.5%0.5%0.5%Stearic acid0.7%0.7%0.7%Cetearyl glucoside1.0%1.0%1.0%Creatine0.5%0.5%0.5%Glycerol3.0%3.0%3.0%Kathon CG0.015% 0.015% 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com