Solid-state imaging device, production method thereof, and electronic device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

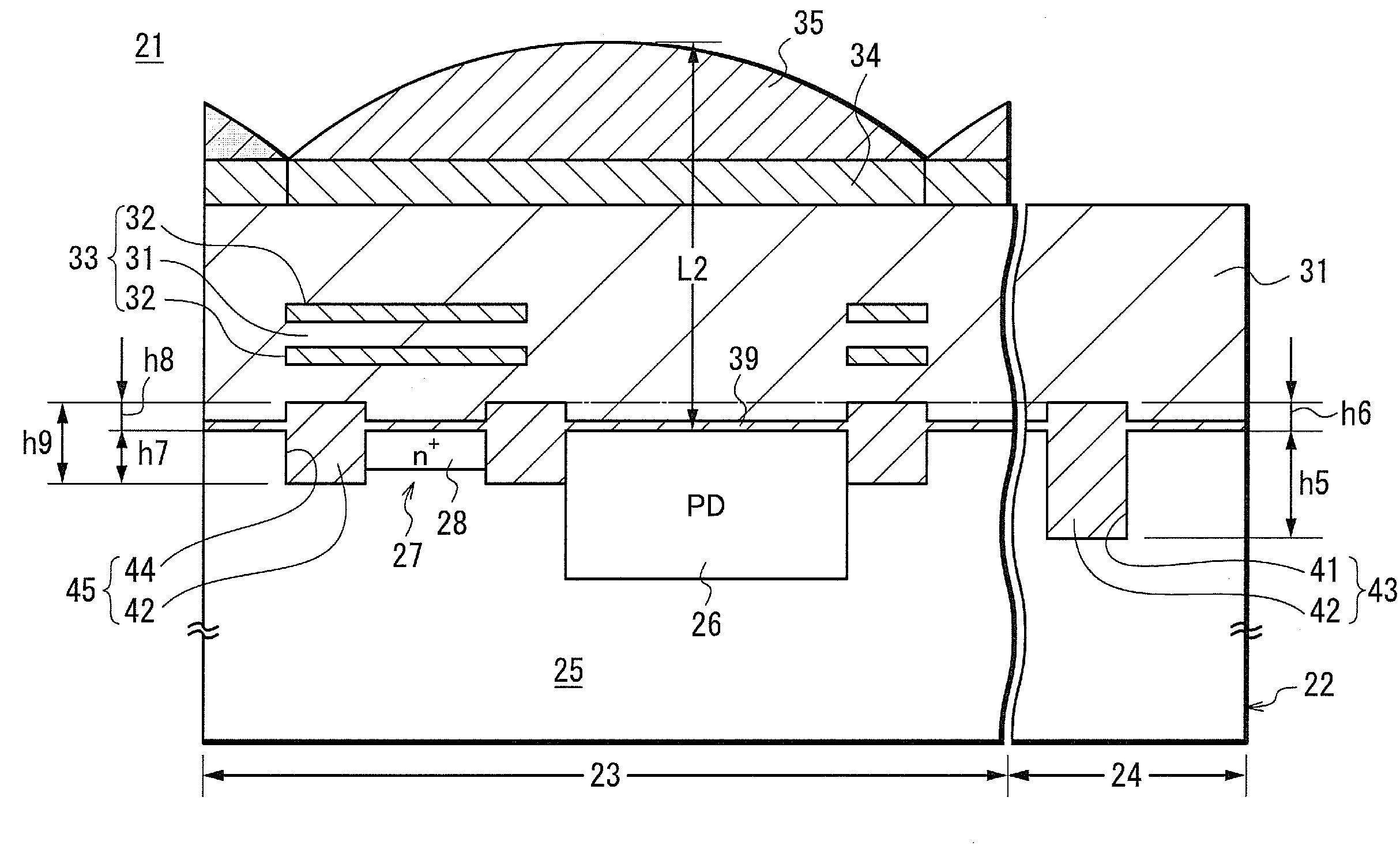

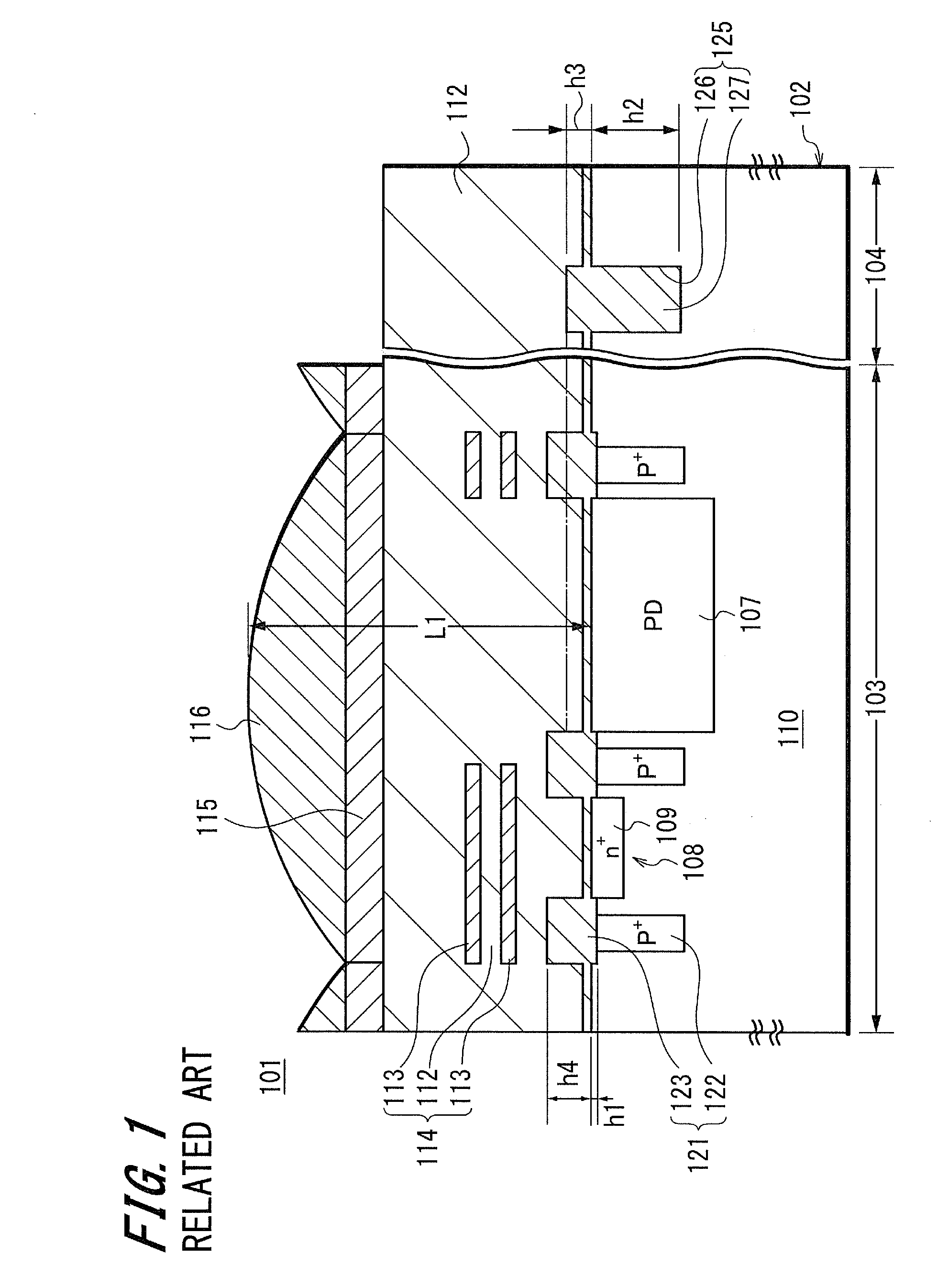

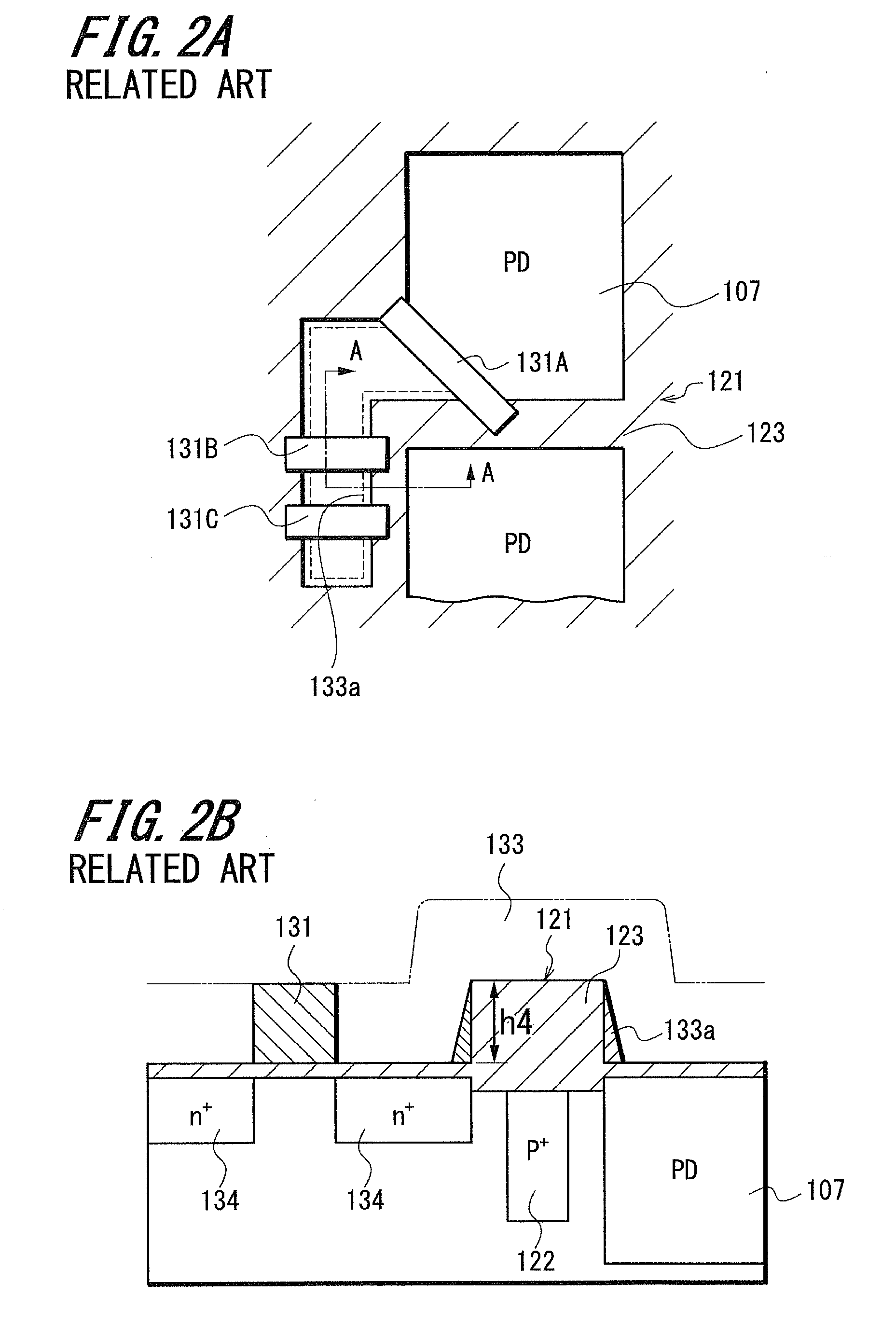

of the Production Method

[0116]In the next place, a first embodiment of the production method for the solid-state imaging device according to the present invention will be described with reference to FIGS. 13A through 17J. The present embodiment is adapted to producing the solid-state imaging device according to the aforementioned second embodiment of the solid-state imaging device shown in FIG. 6, in particular to forming isolation regions thereof.

[0117]First, referring to FIG. 13A, a thin insulator film 39 is formed having a first predetermined film thickness on a major surface of a semiconductor substrate 22, and subsequently formed on the insulator film 39 is another insulator film 61 having a second predetermined film thickness with an etching rate different from that of the insulator film 39. As the insulator film 39, a silicon oxide film may be used, for example. As the insulator film 61, a silicon nitride film formed by low pressure CVD of about 100 nm in film thickness may b...

second embodiment

of the Production Method

[0131]In the next place, a second embodiment of the production method for the solid-state imaging device according to the present invention will be described with reference to FIGS. 18A through 22. The present embodiment is adapted to producing the solid-state imaging device according to the aforementioned second embodiment of the solid-state imaging device shown in FIG. 6, in particular to the isolation region thereof.

[0132]First, referring to FIG. 18A, a thin insulator film 39 is formed having a first predetermined film thickness on a major surface of a semiconductor substrate 22, and subsequently formed on the insulator film 39 is another insulator film 61 having a second predetermined film thickness with an etching rate different from that of the insulator film 39. As the insulator film 39, a silicon oxide film may be used, for example. As the insulator film 61, a silicon nitride film formed by the low pressure CVD of about 100 nm in film thickness may be...

third embodiment

of the Production Method

[0142]Next, referring to FIG. 23 through FIG. 25, a third embodiment of the production method for the solid-state imaging device according to the present invention will be described. The present embodiment is adapted to producing the solid-state imaging device 55 according to the fifth embodiment shown in FIG. 9, in particular, to forming the isolation region thereof.

[0143]In the production method according to the third embodiment, first, as illustrated in FIG. 23A, using the processes shown in FIG. 13A through FIG. 15E or in FIG. 18A through FIG. 19D, shallow trenches 44 and deep trenches 41 are formed in pixel sections 23 and peripheral circuit sections 24, respectively. FIG. 23A shows a state that a thin insulator film 39 for example of a silicon oxide film is formed on the surface of a semiconductor substrate 22 where the trenches 44 and 41 are not formed and an insulator film 61 for example of a silicon nitride film is formed thereupon.

[0144]Next, as ill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com