Shaped part of an ultra high molecular weight polyethylene

a polyethylene and ultra-high molecular weight technology, applied in the field of shaped parts of ultra-high molecular weight polyethylene, can solve the problems of inability to meet the requirements of high molecular mass polymers, and insufficient product performance, so as to achieve good processability below the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

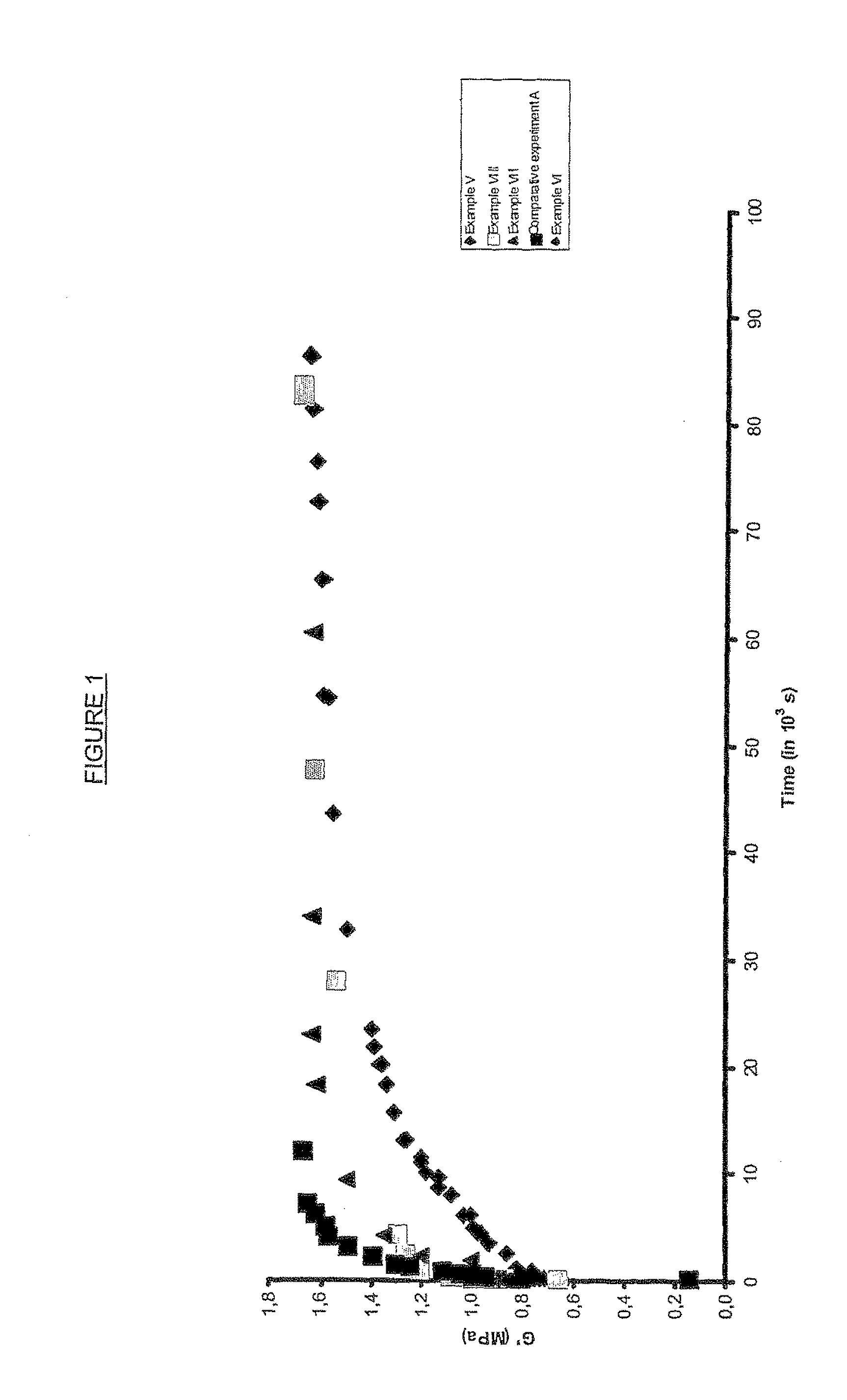

Examples

examples v

and VI

Catalyst is (C5Me5)2Sm(THF)2

[0040]The polymerizations were carried out at −10 and 0° C., respectively, under atmospheric pressure using a 2000 ml round bottom flask, equipped with a thermocouple and a mechanical stirrer. Petroleum ether (1000 ml) was introduced to the argon-purged reactor after which the solvent was saturated by bubbling ethylene into the solution for 45 minutes at −10° C. and 0° C. resp. The polymerization was initiated by addition of a toluene solution of catalyst (2.8 μmol) into the reactor while stirring vigorously. The same amount of catalyst was added ten times at an interval of one minute. The polymerization was quenched after 15 min with methanol. The solid UHMWPE was recovered by filtration, washed with water and acetone and dried (vacuum oven 60° C., overnight).

examples vii

and VIII

Catalyst is [3-tBu-2-O—C6H3CH═N(C6F5)]2TiCl2

[0041]The polymerizations were carried out under atmospheric pressure using a 2000 ml round bottom flask, equipped with a thermocouple and a mechanical stirrer. Petroleum ether (1000 nil) was introduced to the argon-purged reactor after which the solvent was saturated by bubbling ethylene into the solution for 30 minutes at −10° C. and +20° C., respectively. The polymerization was initiated by addition of a toluene solution of methylalumoxane (20 ml) after which a toluene solution of the catalyst (1 μmol) was introduced into the reactor while stirring vigorously. After 20 minutes the ethylene feed was stopped and isobutyl alcohol was added to terminate the polymerization. HCl and water were added to the resulting mixture. The solid UHMWPE was recovered by filtration, washed with water and acetone and dried (vacuum oven 60° C., overnight).

SynthesisExampleCatalysttemp (° C.)MwMnMWDVSm−101,225,500607,7002.0VI02,040,500832,8562.5VIITi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com