LNG tanker and method for marine transportation of LNG

a technology of liquefied natural gas and tanker, which is applied in the direction of special-purpose vessels, load accommodation, transportation and packaging, etc., can solve the problems of irregular shape and require laborious heat-insulating works, and achieve the effect of reducing sloshing in the membrane type, reducing sloshing, and being easy to constru

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

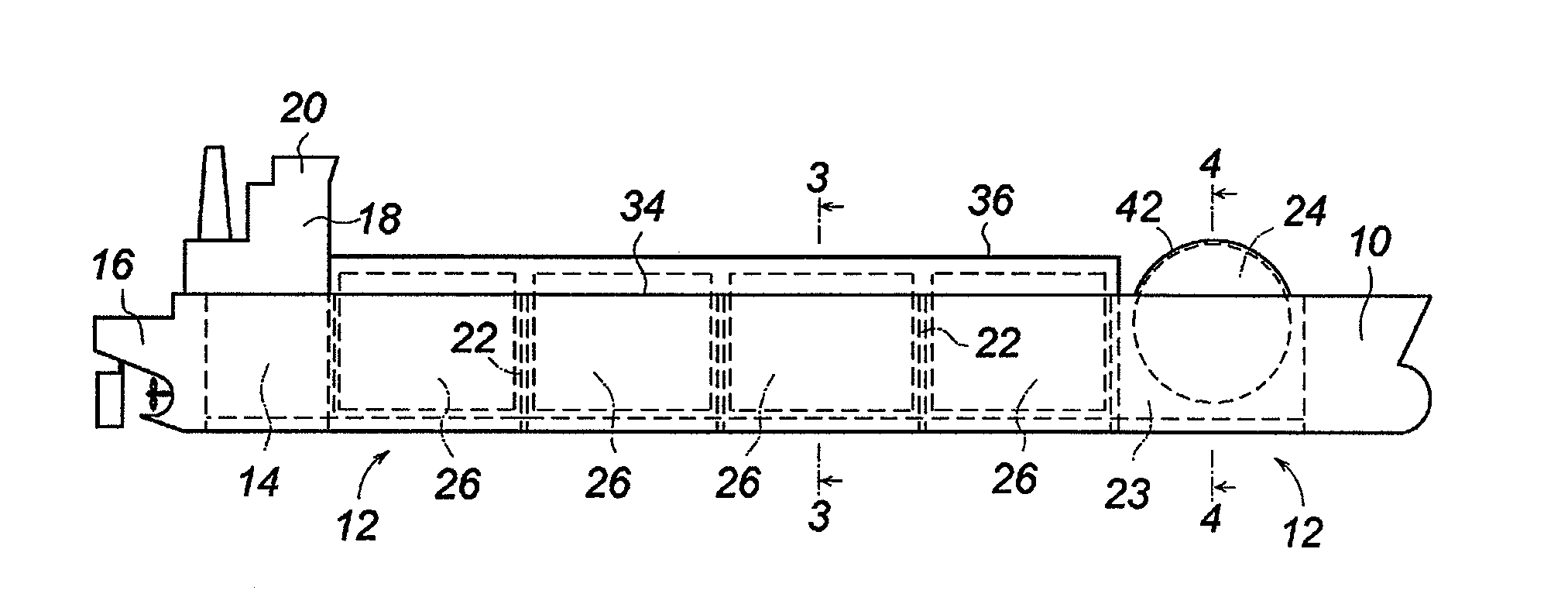

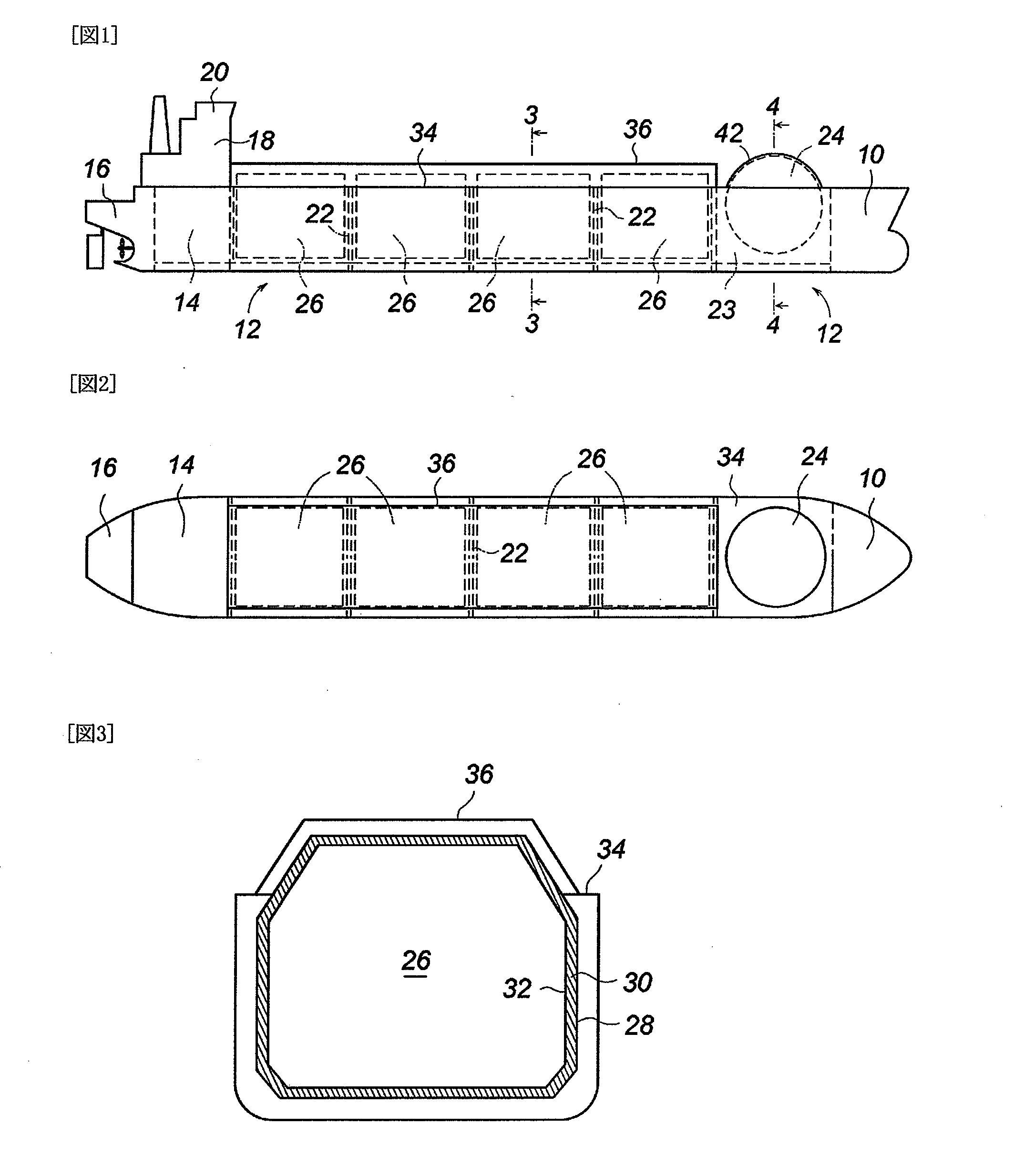

[0020]Referring now to the FIG. 1 and FIG. 2, there is shown an LNG tanker which includes a bow portion 10, a tank section 12, an engine room 14 and a stern portion 16 in succession. On the engine room stands an accommodation space 18 and a steering room 20 thereon. The tank section 12 is divided by transverse bulkheads 22 into a plurality of divisions, the foremost division 23 of which is equipped with a spherical free-standing type tank 24, and each of other subsequent divisions form membrane type tank 26.

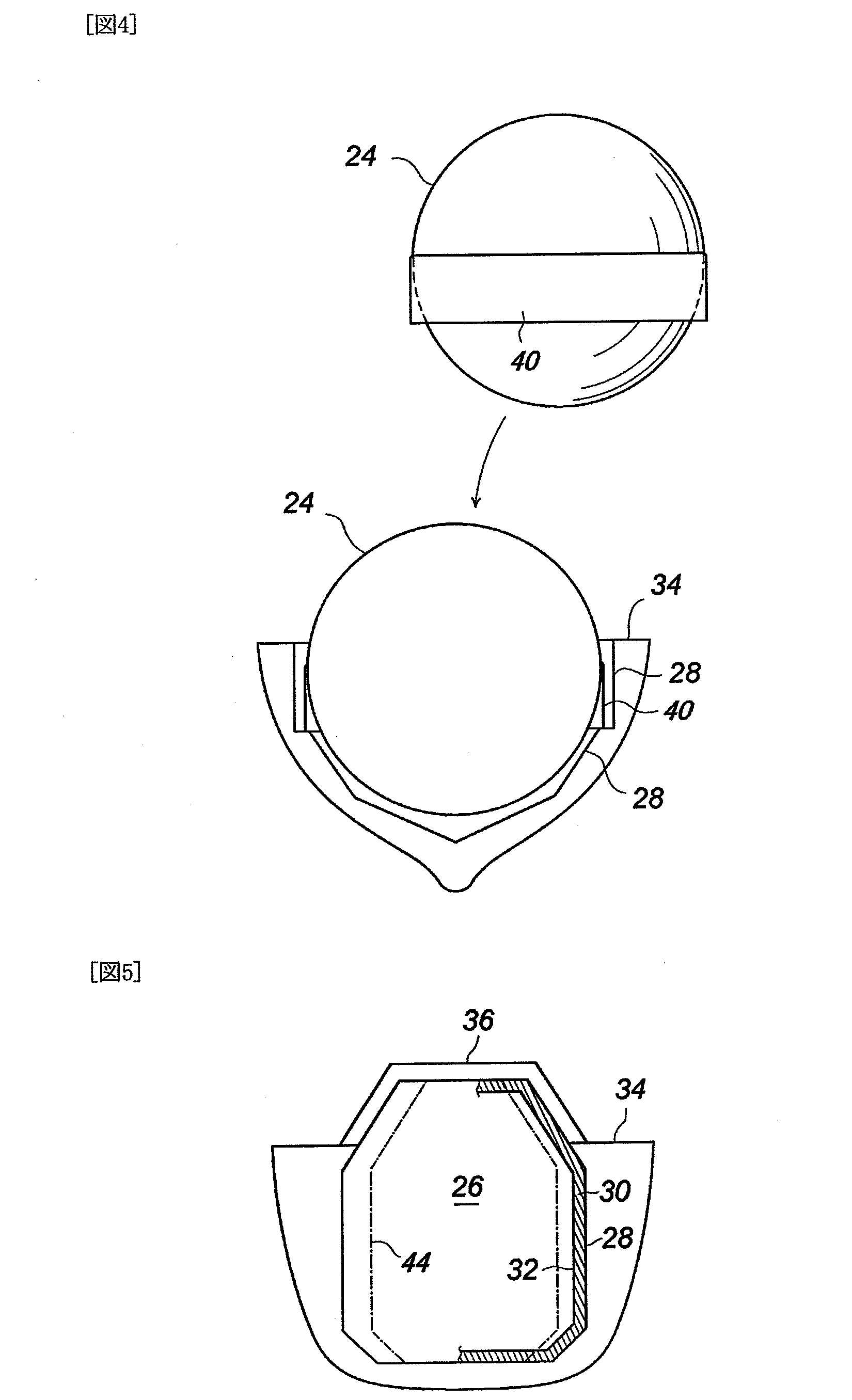

[0021]As shown in FIG. 3, each membrane type tank 26 is surrounded by double hull structures; its inner hull 28 are covered with thermally insulation material 30, which is liquid-tightly covered by a membrane materials 32. The membrane tank 26 has a head portion which protrudes upward through an upper deck 34 to increase the tank capacity, and the head portion is covered with a trunk deck 36.

[0022]FIG. 4 shows a transverse sectional view of the foremost division in which the sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com