Hydrogen storage alloy, preparation process thereof, and hydrogen storage device

a technology of hydrogen storage and alloy, which is applied in the field of hydrogen storage alloy, preparation process thereof, and hydrogen storage device, can solve the problem of small hydrogen storage amount per weight, and achieve the effects of increasing initial effective hydrogen amount, increasing plateau pressure, and improving cycle durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 6

, Comparative Examples 1 to 3

1. Preparation of Sample

[0101]Raw materials mixed at a predetermined ratio were arc-melted to obtain an ingot. The ingot thus obtained was heat-treated at 1300 to 1350° C. in an Ar atmosphere. The alloy thus heat-treated is then subjected to activation treatment once at 300 to 450° C.

2. Test Method

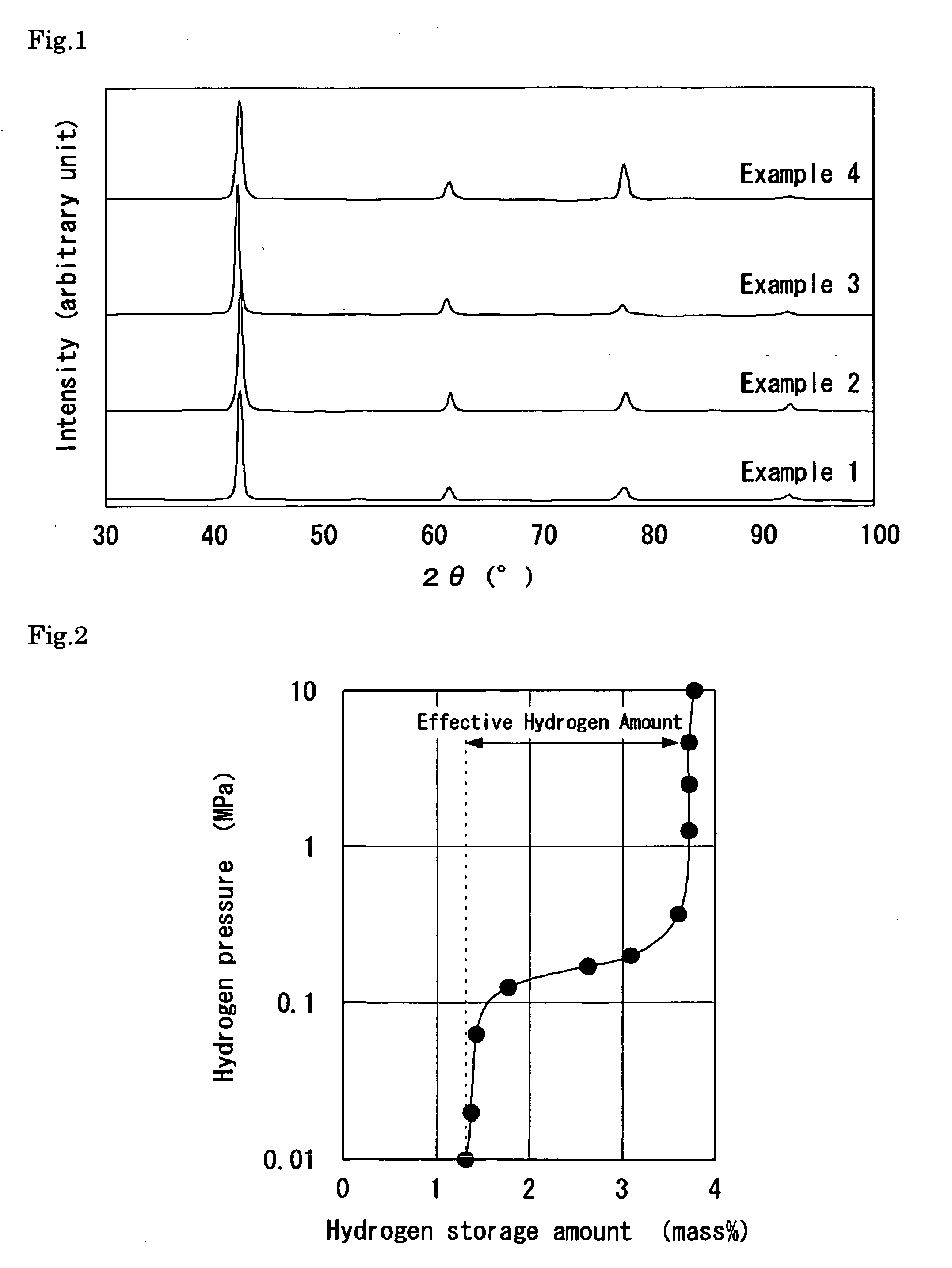

2.1. X-Ray Diffraction

[0102]The X-ray diffraction measurement of the alloy subjected to the heat-treatment was performed. From the resulting X-ray diffraction pattern, a lattice constant was determined.

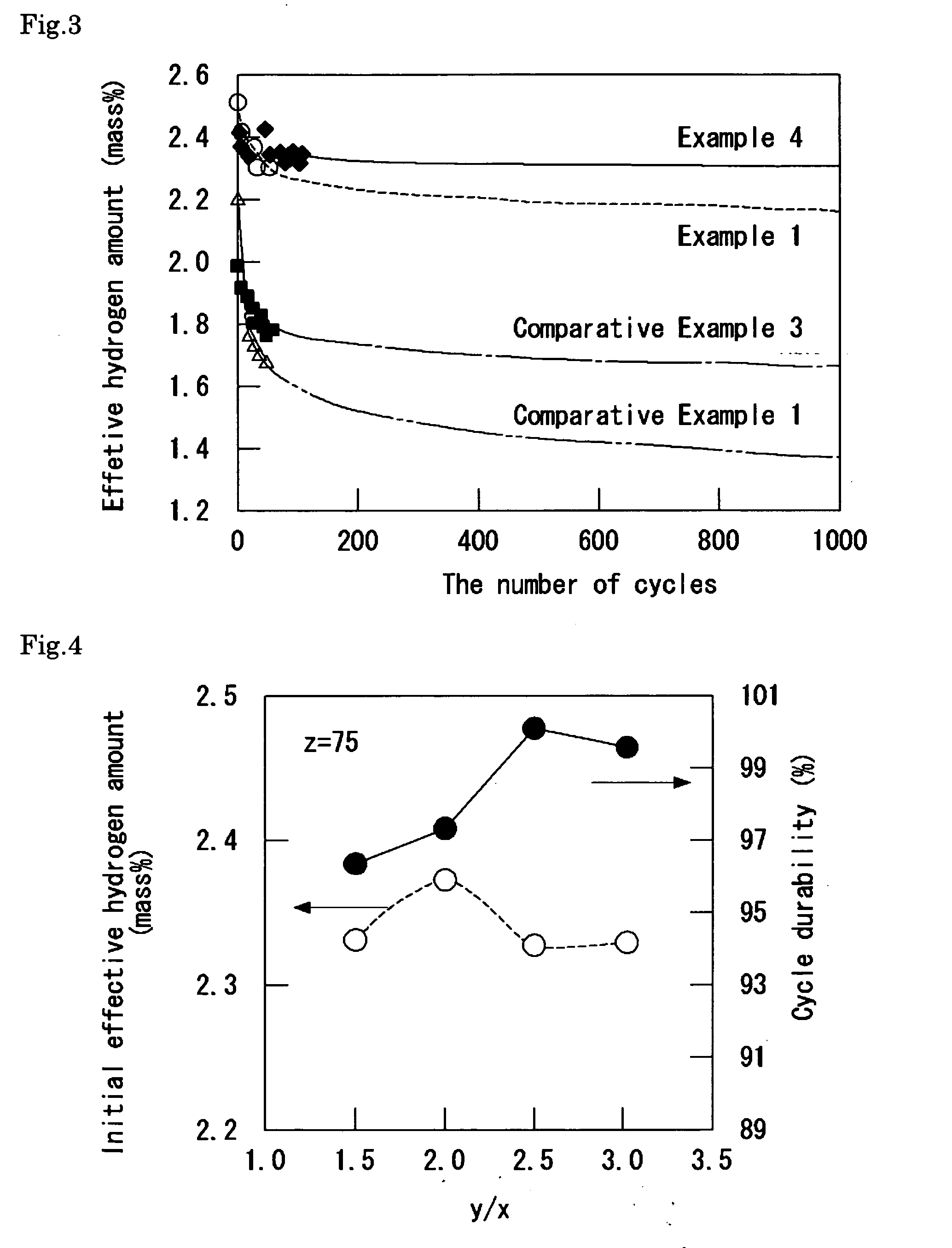

2.2. Hydrogen Storage / Release Characteristics

[0103]The pressure-composition isotherm measurement of the alloy subjected to the activation treatment was performed for 10 cycles at a temperature from −20° C. to a room temperature. Based on the initial effective hydrogen amount and the effective hydrogen amount at 10th cycle, a maintenance ratio (=(effective hydrogen amount at 10th cycle)×100 / initial effective hydrogen amount (%)) was determined.

[0104]Further, the p...

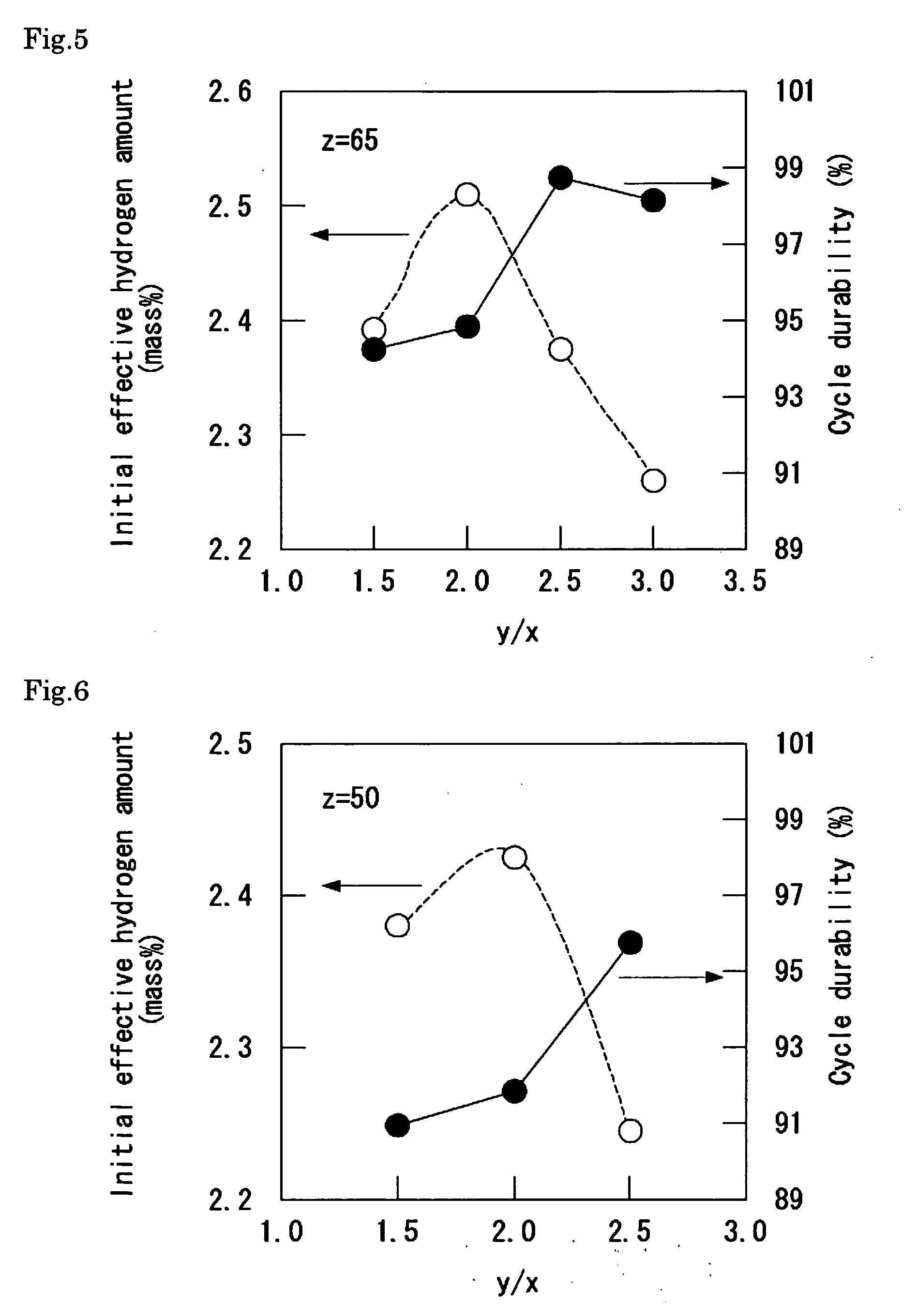

example 7

1. Preparation of Sample

[0115]In a similar manner to Example 1, various TixCryVz alloys different in y / x ratio and z were prepared.

2. Test Method

[0116]In a similar manner to Example 1, an initial effective hydrogen amount and an effective hydrogen amount at 10th cycle were measured at from 0 to 50° C. and a maintenance ratio (cycle durability) was determined based on them.

3. Results

[0117]FIGS. 4 to 10 show initial effective hydrogen amounts and cycle durability of various TixCryVz alloys. FIGS. 4 to 10 reveal the following findings:

[0118](1) Within a range of 3 / 1.65≦y / x≦3 / 1, the initial effective hydrogen amount reaches the maximum value and at the same time, an increase in the y / x ratio leads to improvement in cycle durability.

[0119](2) Within a range of 3 / 2≦y / x≦3 / 1 and 65≦z≦75, the initial effective hydrogen amount becomes 2.2 mass % or greater and the cycle durability becomes 94% or greater.

[0120](3) Within a range of 3 / 2≦y / x≦3 / 1.2 and 50≦z<65, the initial effective hydrogen amou...

example 8

[0133]A V40Ti18.4Cr41.6 alloy was prepared by arc melting V, Ti, and Cr and then heat-treating the resulting ingot at 1300° C. in an Ar atmosphere. The X-ray diffraction analysis of the resulting alloy was performed. It revealed that the alloy had, as a main phase thereof, a BCC phase. Pressure-composition isotherm measurement of the heat-treated alloy at 0° C. was performed 10 cycles. The initial effective hydrogen amount was 2.29 mass %. On the other hand, the effective hydrogen amount at the 10th cycle was 2.07 mass % (90% of the initial amount).

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| composition | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com