Microbial fuel cell

a fuel cell and microorganism technology, applied in the field of microorganism fuel cells, can solve the problem of too large cells to be of practical valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

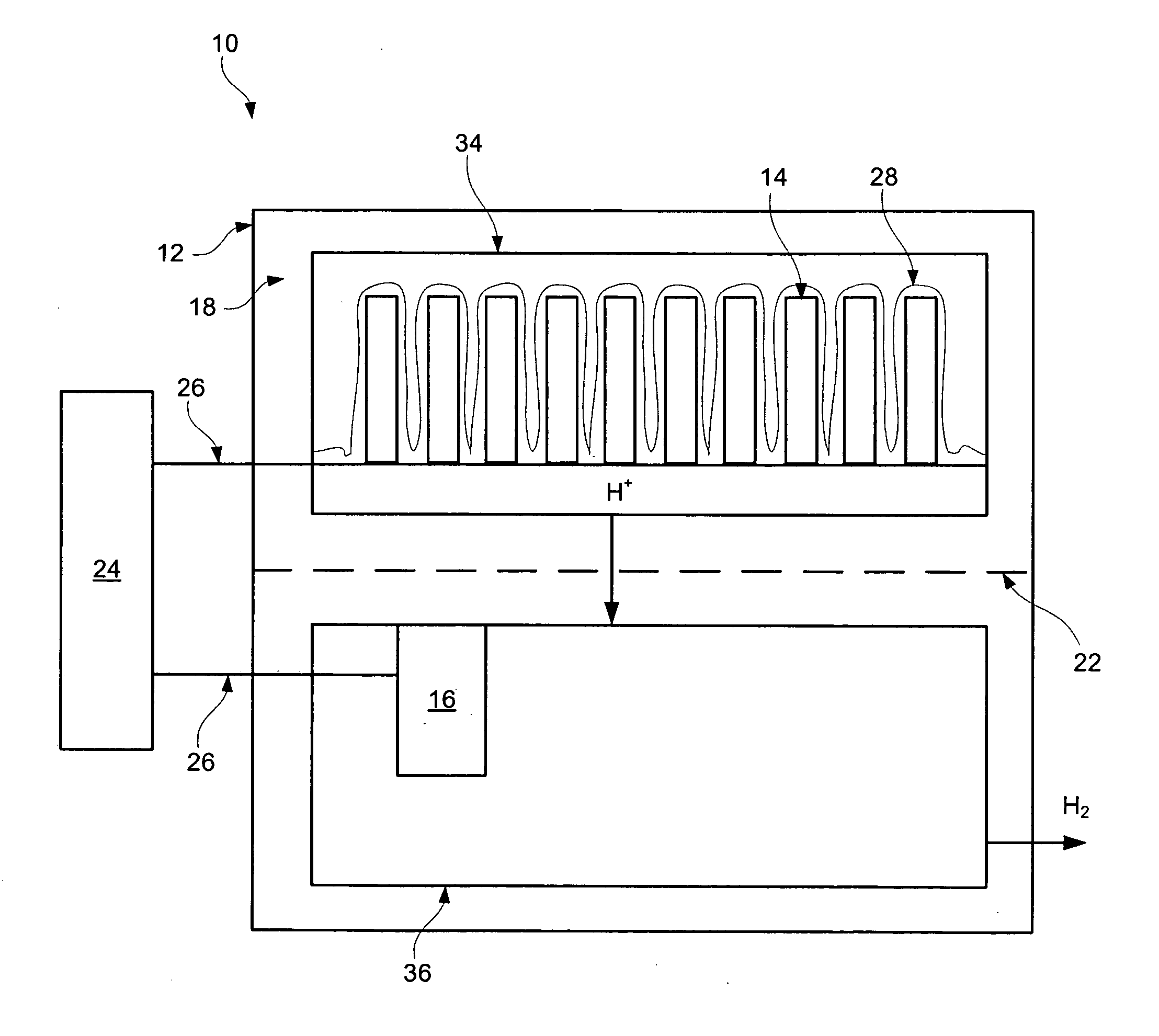

Image

Examples

example 1

Development of Static Biofilms on Simple Glass Surfaces in Feedstock

[0080]Circular glass coverslips were attached to the bottom of 35×10 mm polystyrene tissue culture dishes with small holes in the base (Falcon). The plates were exposed to UV irradiation overnight. (UV irradiation sterilizes the culture plates).

[0081]Bacterial cells were grown in Luria Bertani media (LB) overnight.

[0082]Aerobic LB, aerobic LBN (LB+1% KNO3), or anaerobic LBN (3 ml) was placed in each tissue culture plate. The media was inoculated with 107 cfu of bacterial cells. The plates were incubated at 37° C. for 24 hours. The media was removed and the plates were washed with saline buffer. LIVE / DEAD BacLight (Molecular Probes, Inc) bacterial viability stain (0.5 ml) was added to each plate. Images were acquired on a Zeiss LSM 510 laser scanning confocal unit attached to an Axiovert microscope with a 63×14 NA oil immersion objective. For two color images, samples were scanned sequentially at 488 nm and 546 nm. S...

example 2

Culture Media

[0083]LB media is 10 g / liter tryptone, 5 g / liter yeast extract, and 5 g / liter NaCl.

[0084]LBN media is 10 g / liter tryptone, 5 g / liter yeast extract, 5 g / liter NaCl and 10 g / liter KNO3.

example 3

Development of Biofilms in Circulated Feedstock

[0085]Bacteria are grown aerobically in LB at 37° C. until the stationary growth phase. Bacteria are diluted 1:50 into 1% trypticase soy broth. Flow cells are inoculated with 0.2 ml diluted bacteria. Flow cells and bacteria are incubated for 1 hour. After an hour, flow is initiated at a rate of 0.17 ml / min. The cells are incubated 3 days at room temperature. The cells are stained with a live / dead viability stain composed of SYTO 9 and propidium iodine (Molecular Probes, Inc.). Biofilm images are obtained using an LSM 510 confocal microscope (Carl Zeiss, Inc.). The excitation and emission wavelengths for green fluorescence are 488 nm and 500 nm, while those for red fluorescence are at 490 nm and 635 nm, respectively. All biofilm experiments are repeated at least 3 times. The live / dead ratios of the biofilms are calculated using the 3D for LSM (V.1.4.2) software (Carl Zeiss). Overall biofilm structure such as thickness, water channel, bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com