Vacuum cleaner head

a vacuum cleaner and vacuum head technology, applied in the field of vacuum cleaners, can solve the problems of paper bag contamination, dust and debris being lifted and stored,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

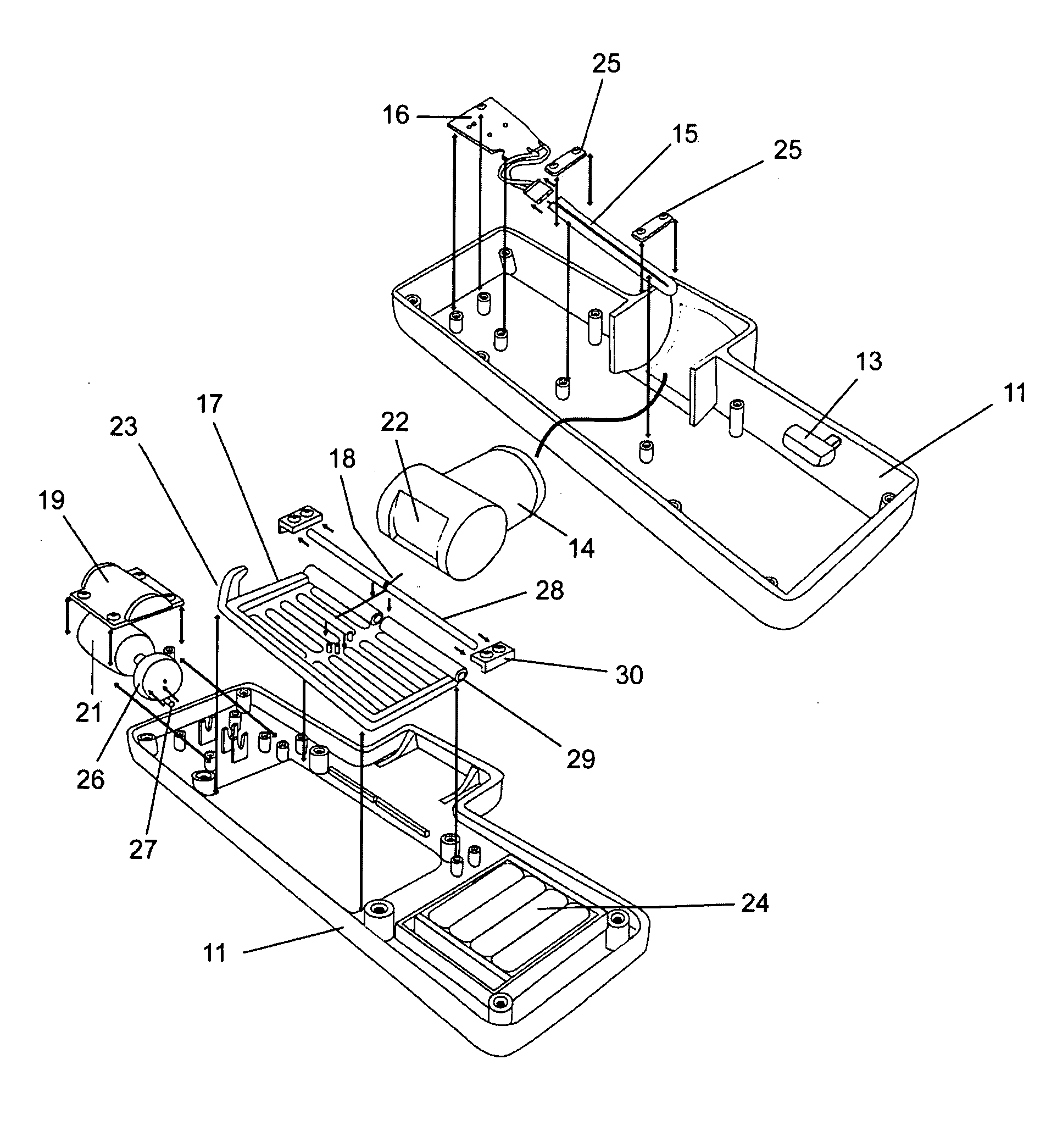

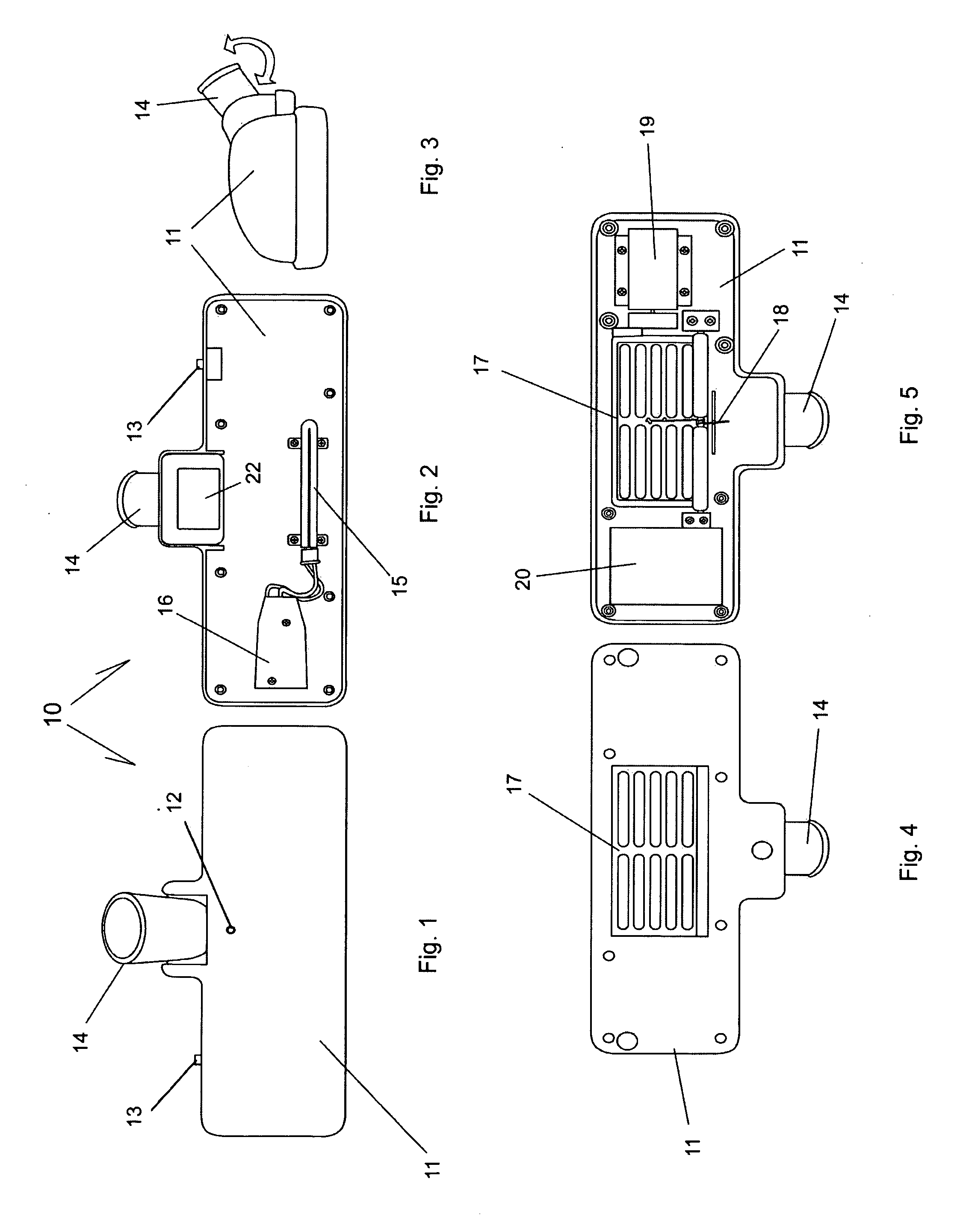

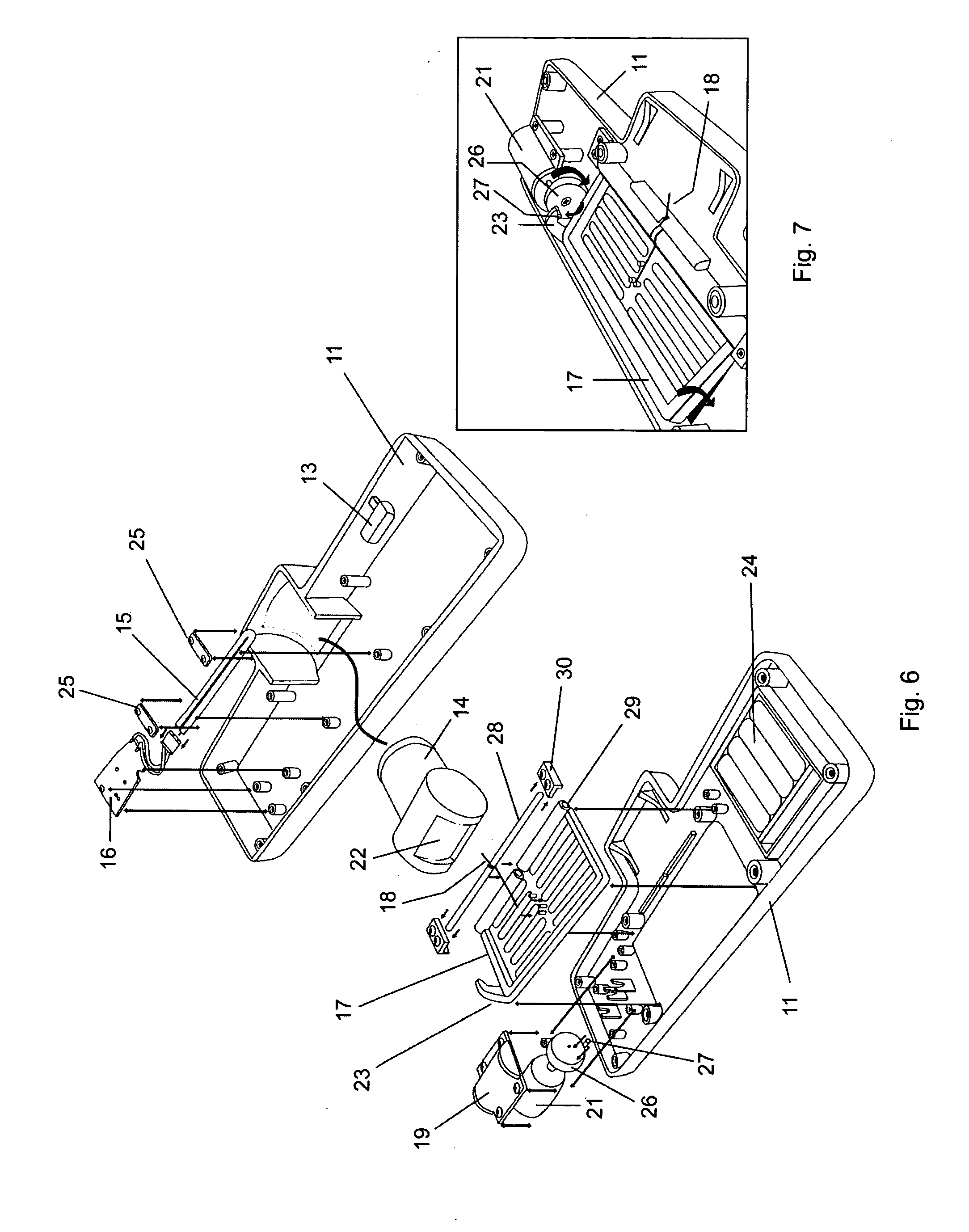

[0026]In the accompanying drawings there is depicted schematically a vacuum cleaner head 10 comprising a body 11 typically formed as a thermoplastics moulding. The body has pivotally extending from it a vacuum hose or pole attachment 14 via which air is drawn through the body en route to a vacuum cleaner.

[0027]Inside the body there is provided a PCB 16 having wires extending to an ultraviolet fluorescence lamp 15.

[0028]A covered battery compartment 20 houses a number of batteries 24. A switch 13 conveys power from the batteries 24 to the PCB 16. A power indicator LED 12 is provided upon the body 11 to indicate that the switch 13 is in the ON position.

[0029]Pivotally attached to the underside of the body 11 is a perforated agitation plate 17. The agitation plate 17 includes a hinge 29 through which a hinge pin 28 extends. A pair of hinge clamps 30 secures the hinge pin 28 to the body 11. Integrally moulded with the agitation plate 17 is a cam follower 23.

[0030]An electric motor 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com