Substrate preparation using megasonic coupling fluid meniscus

a technology of megasonic coupling fluid and substrate, which is applied in the direction of cleaning process and apparatus, cleaning using liquids, chemistry apparatus and processes, etc., can solve the problems of defective semiconductor wafers, high cost, and high time consumption of wet operations, so as to improve the preparation and/or cleaning operation of substrates, improve the effect of preparation chemical mass transport and improve the effect of substrate preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

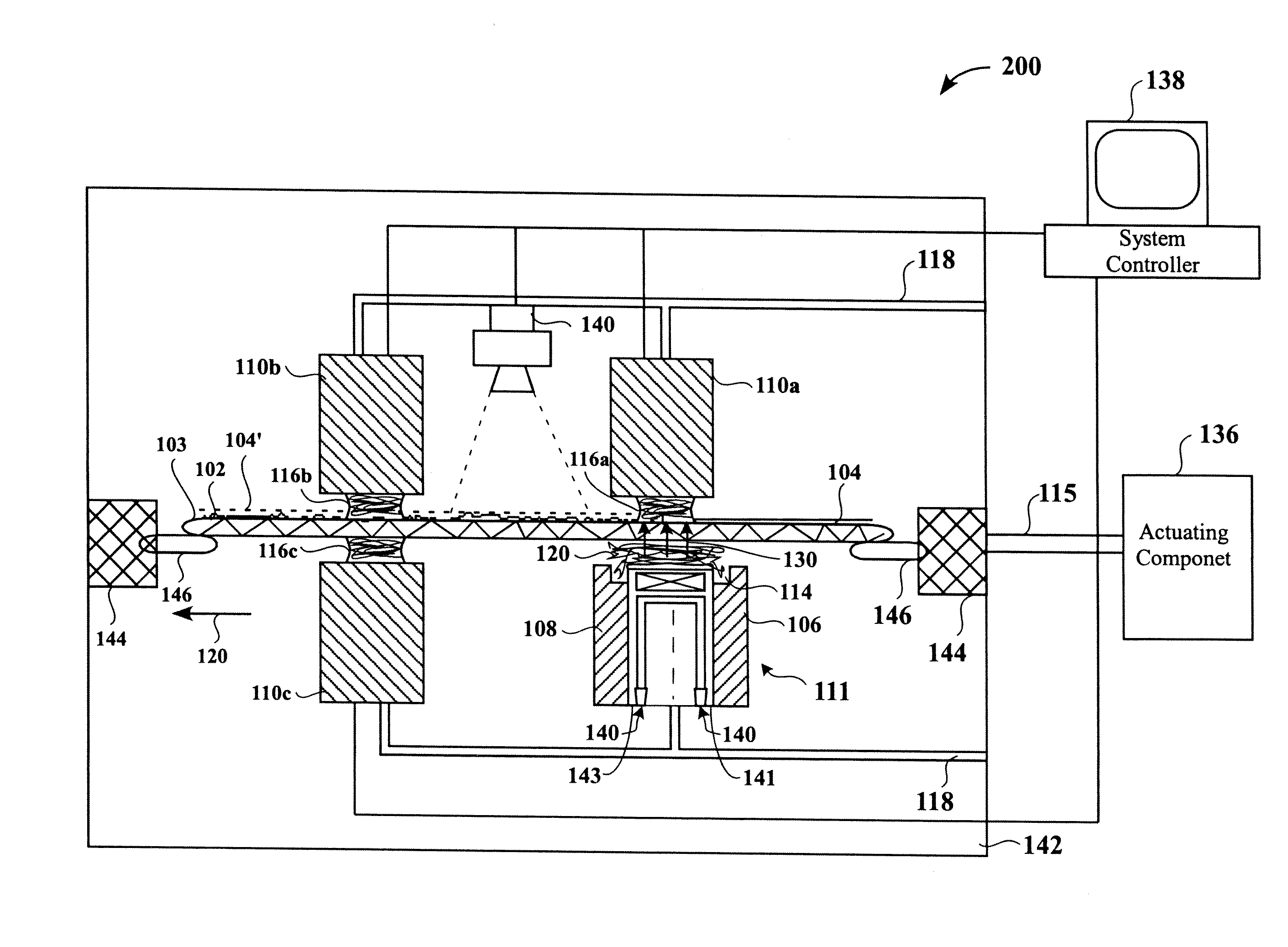

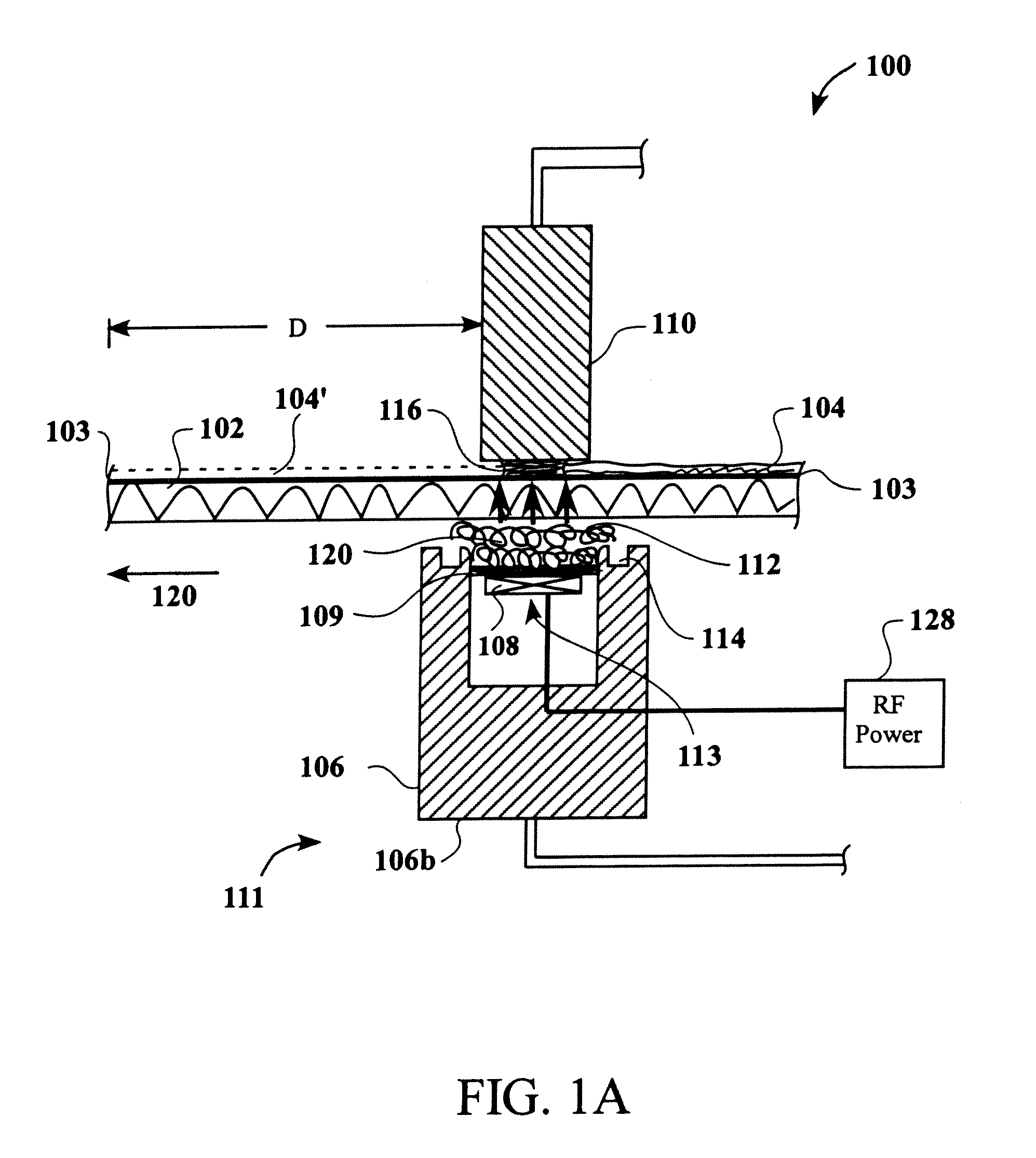

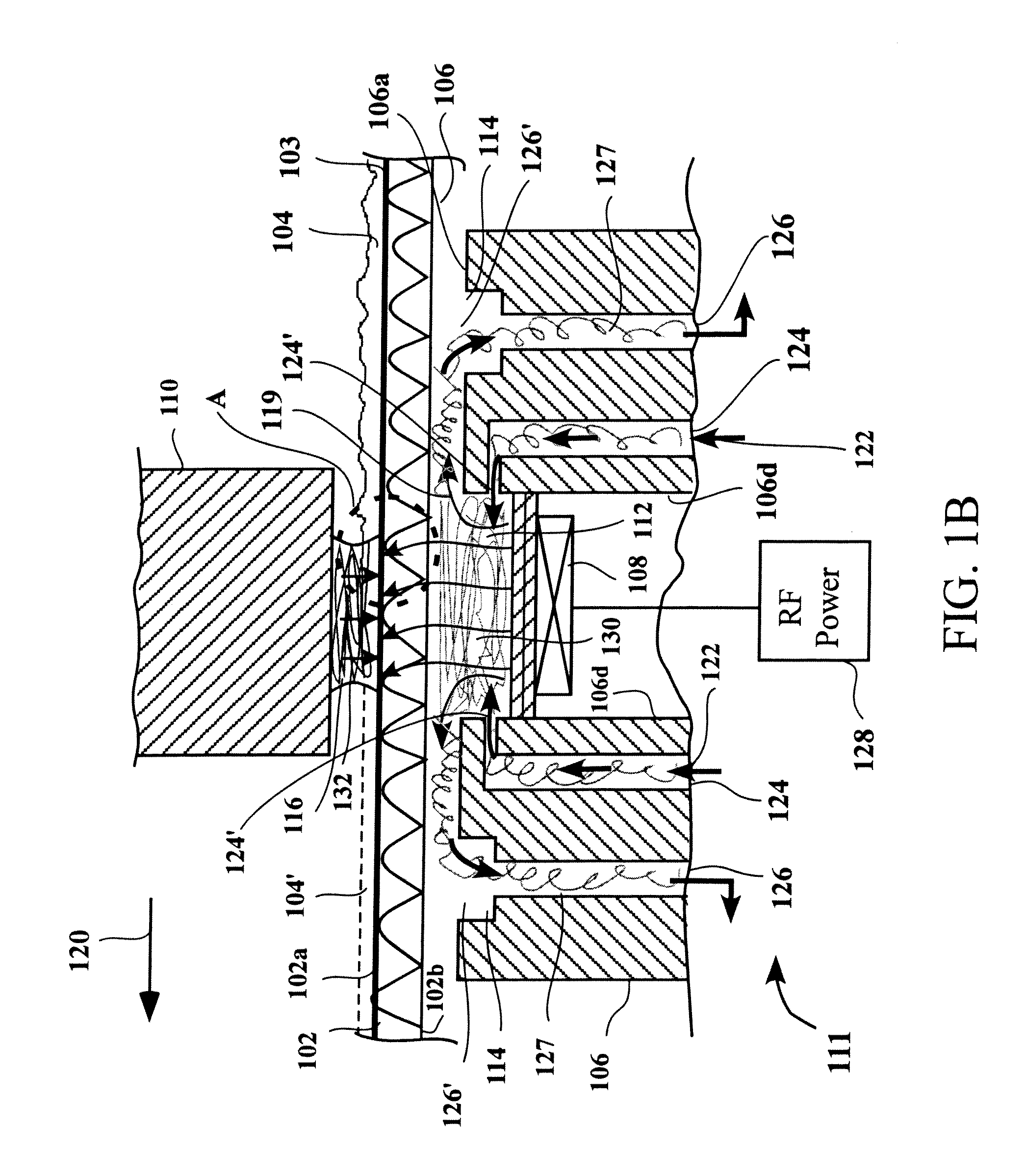

[0031]An invention capable of improving substrate preparation and / or cleaning operations without substantially damaging semiconductor devices formed on substrate frontsides is provided. In one example, the present invention improves substrate preparation and / or cleaning operations by enhancing a mass transport of preparation chemistry to a reaction interface on the substrate frontside. According to one aspect, the enhancing of the mass transport of the preparation chemistry to the reaction interface is achieved by imparting megasonic energy to the interface through a megasonic coupling fluid meniscus coupled to a backside of the substrate. In one example, the megasonic energy imparted to the reaction interface further assists in breaking a bond or a force between the material to be removed and / or the residues or particulate contaminants, and the substrate frontside at the reaction interface, thus resulting in the removed of the residues, particulate contaminants, and / or the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com