Multijunction photovoltaic cell grown on high-miscut-angle substrate

a photovoltaic cell and substrate technology, applied in the field of semiconductor materials, can solve the problems of increasing the cost of a launch more than linearly, increasing the cost of a launch, and the cost per watt of electrical power generation capacity of photovoltaic systems, and achieves the effects of high band gap, quantum efficiency, and short cutoff wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The following detailed description describes the best currently contemplated modes of carrying out the invention. The description should not be taken in a limiting sense, but is made merely for the purpose of illustrating the general principles of the invention, since the scope of the invention is best defined by the appended claims.

[0036]The present invention generally provides a high-efficiency MJ photovoltaic cell (such as a GaInP / Ga(In)As / Ge cell) that may be used with, for example, a satellite. Such a high-efficiency MJ photovoltaic cell results from an increased bandgap of the GaInP subcell, due to an increased sublattice disorder induced by growth on a substrate misoriented from a (100) plane toward a (111) plane. Any of the aforementioned conventional methods for disordering GaInP (and other III-V compounds) can be used in conjunction with disordering due to growth on high-miscut-angle substrates of the present invention.

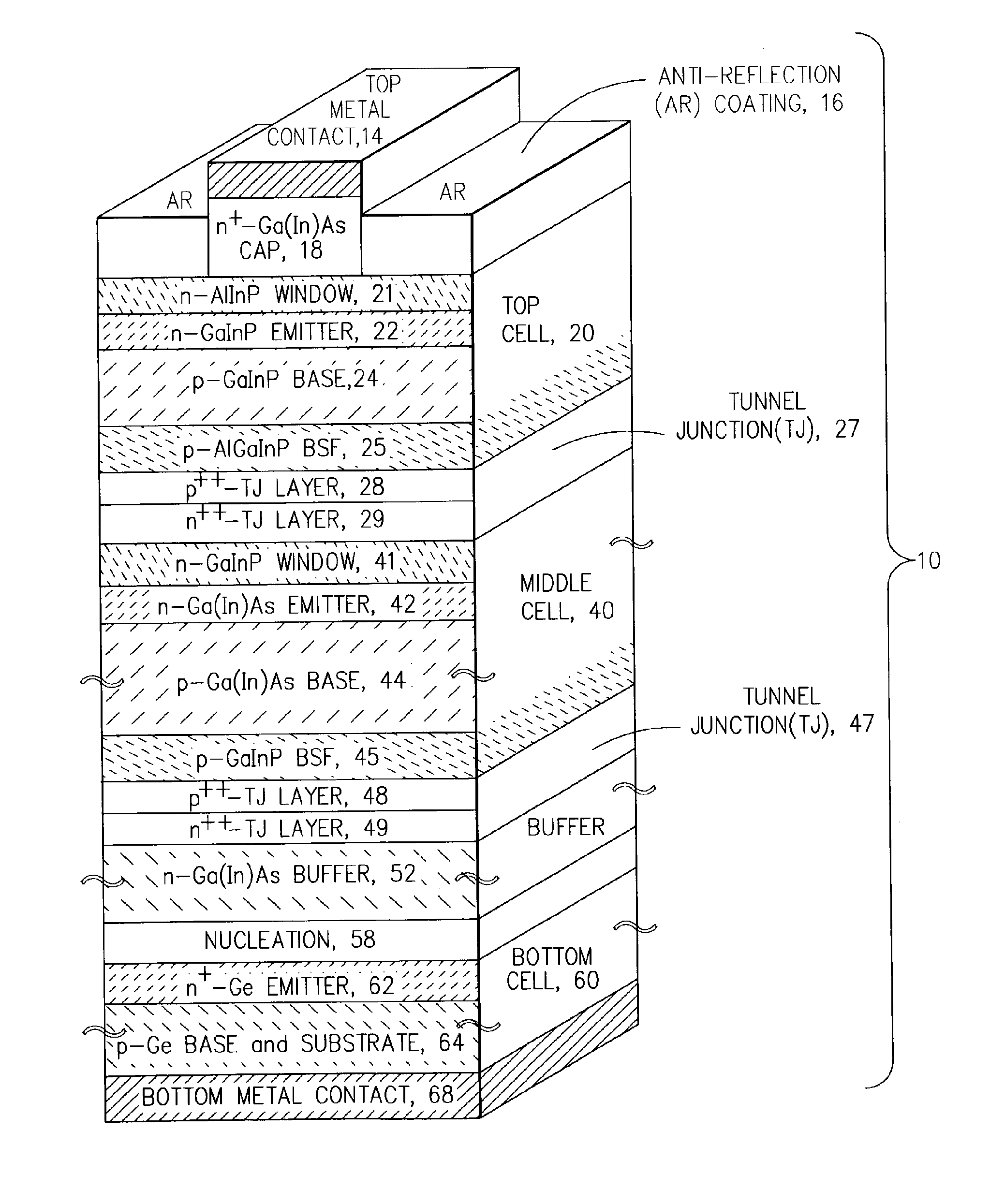

[0037]Referring now to FIG. 1, a cross-section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com