Phase difference layer laminated body for three dimensional liquid crystal display device and manufacturing method thereof

a technology of liquid crystal display device and laminated body, which is applied in the direction of microlithography exposure apparatus, instruments, photomechanical treatment, etc., can solve the problems of limited orientation of resultant phase difference films, inability to meet such demands, and inability to achieve optical compensation with conventional phase difference films, so as to achieve high molecular orientation freedom and manufacturing ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

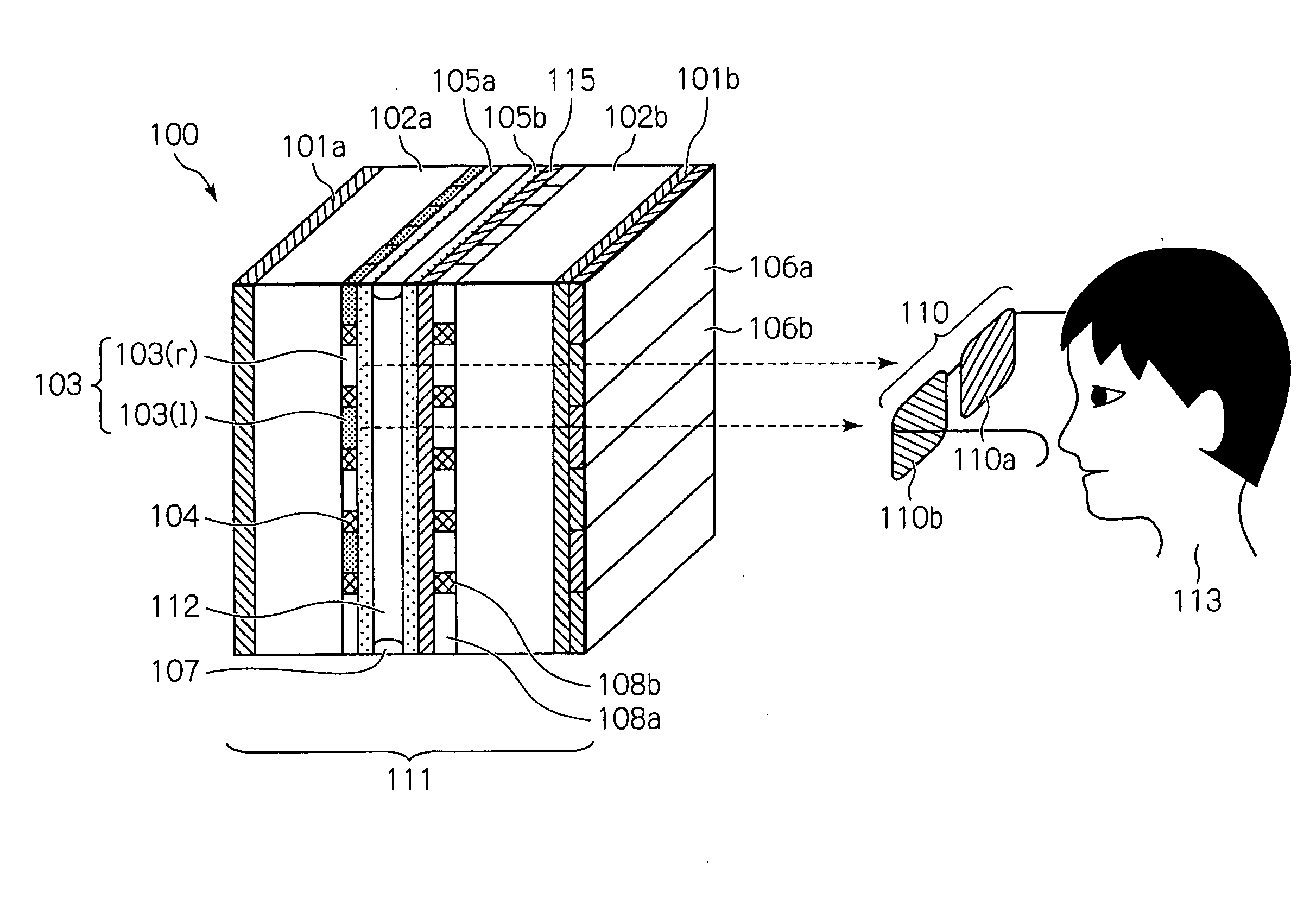

first embodiment

a. First Embodiment

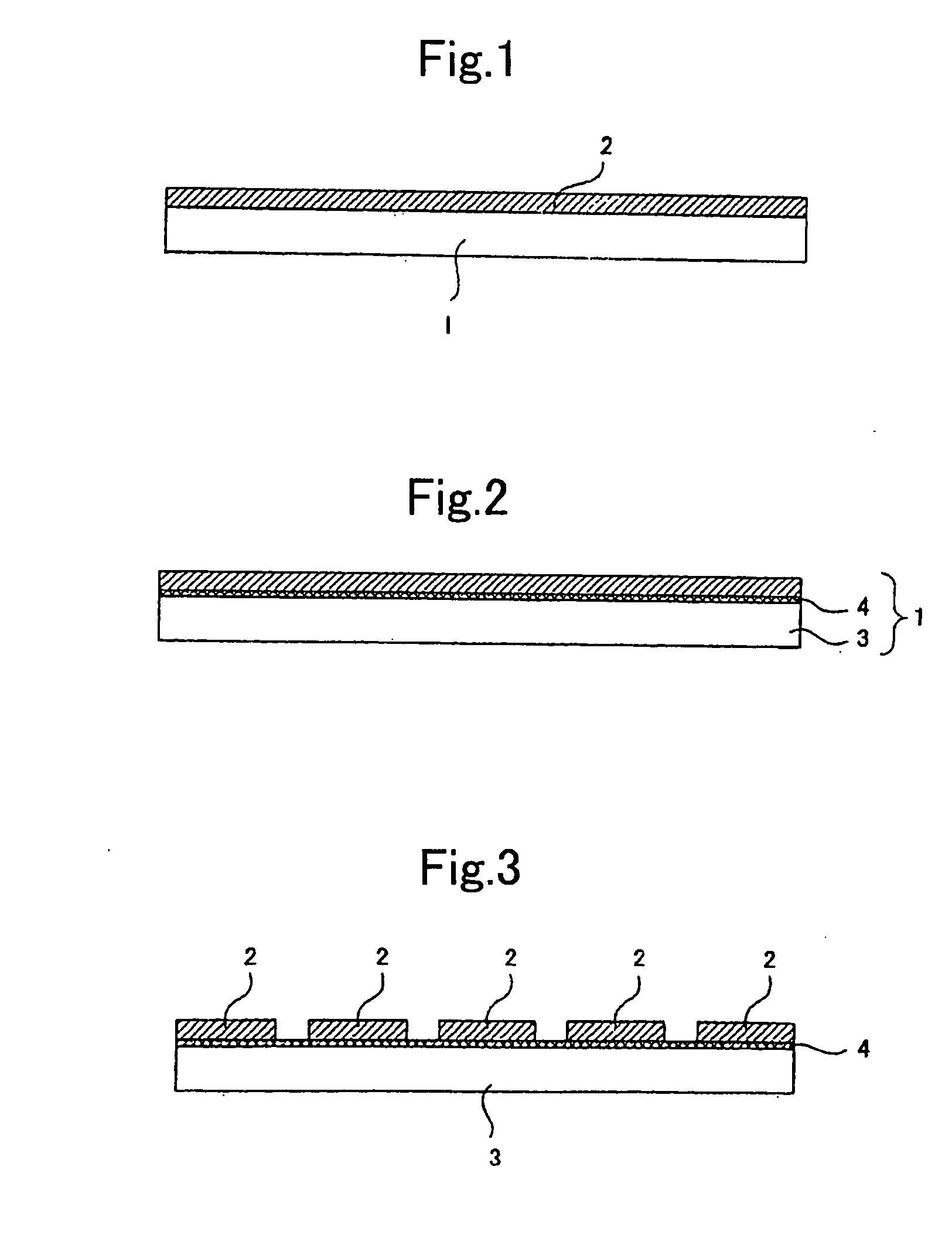

[0063]In this embodiment, the base material itself has orientability; specifically, the base material is a stretched film. With a stretched film, the liquid crystal material can be oriented along a stretched direction of the film. Therefore, the processing of the base material is accomplished simply by preparation of a stretched film, which is a merit that the processing step is made very simple. For the stretched film, any commercially available stretched film can be used, or a stretched film can be made, according to needs, of various materials.

[0064]More specifically, examples of the film include films made of thermoplastic polymers, such as polycarbonate polymers, polyester polymers such as polyarylate or polyethylene terephthalate, polyimide polymers, polysulfone polymers, polyethersulfone polymers, polystyrene polymers, polyolefin polymers such as polyethylene or polypropylene, polyvinyl alcohol polymers, cellulose acetate polymers, polyvinyl chloride polyme...

second embodiment

b. Second Embodiment

[0068]In the second embodiment, the base material having the above orientability comprises a transparent substrate and an oriented film formed thereon.

[0069]With this embodiment, there is a merit that selection of the orientated film enables selection of orientation in a relatively wider range of directions. Selecting the type of liquid applied on the transparent substrate for forming the oriented film allows orientation in various directions and enables even more effective orientation.

[0070]An oriented film commonly used for a liquid crystal display device or the like can favorably be used for the oriented film of this embodiment; generally, an oriented film of polyimide that has undergone rubbing treatment is favorably used.

[0071]For the transparent substrate used in this embodiment, any transparent material can be used, e.g., a transparent and rigid material having no flexibility such as silica glass, Pyrex (registered trademark) glass, and synthetic silica gl...

example

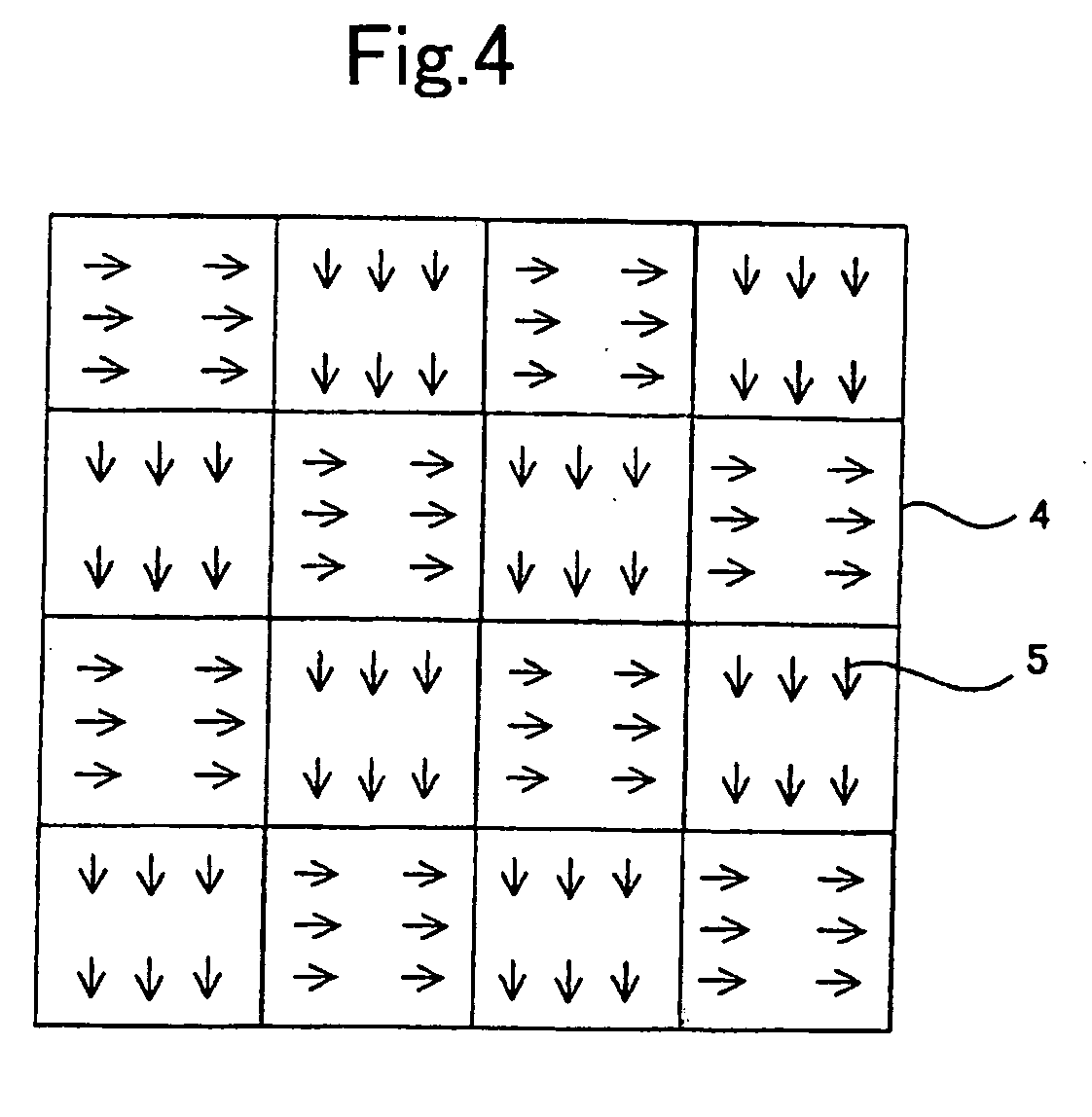

[0182]An example will be described below for further explanation of the invention.

[0183]A solution of polymerizable liquid crystal monomer in toluene was prepared, the monomer having a mesogen in the center, polymerizable acrylate at either end, and a spacer linking therebetween, and having a liquid crystal-isotropic transition temperature (temperature at which liquid crystal transforms into an isotropic phase) of 100.degree. C. Note that, a photopolymerization initiator (Irg 184: Ciba Specialty Chemicals Corp.) was added to the above solution in toluene in an amount of 5% by weight relative to the monomer molecules.

[0184]Meanwhile, polyimide was applied on a glass substrate to form a coat, which then underwent rubbing treatment in certain directions, to form an oriented film.

[0185]This glass substrate with the oriented film was then set in a spin coater, and the above solution in toluene was applied onto the oriented film to a thickness of about 5 .mu.m by spin coating.

[0186]Next, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com