Horizontal type high-temperature hot-blast stove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

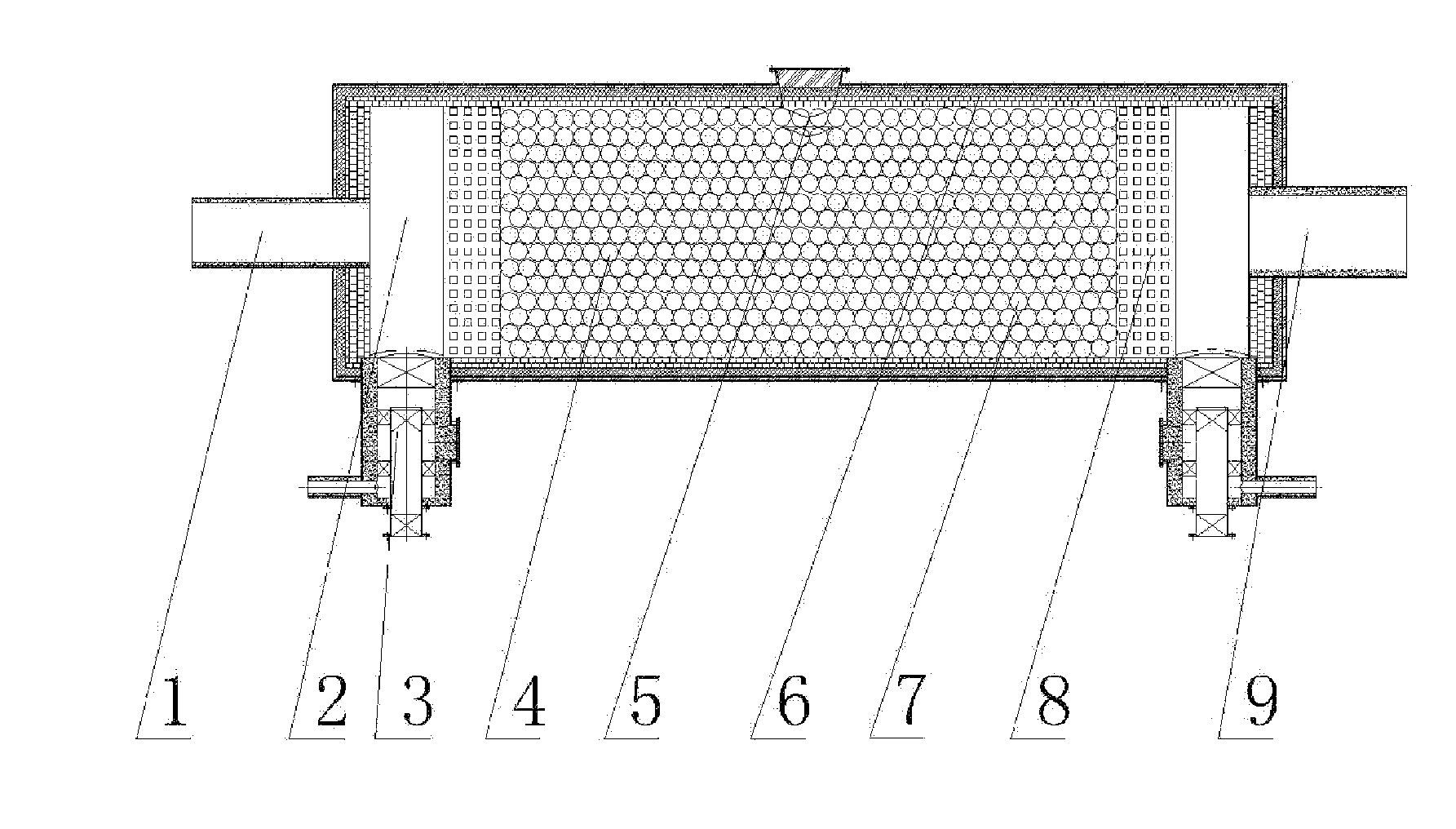

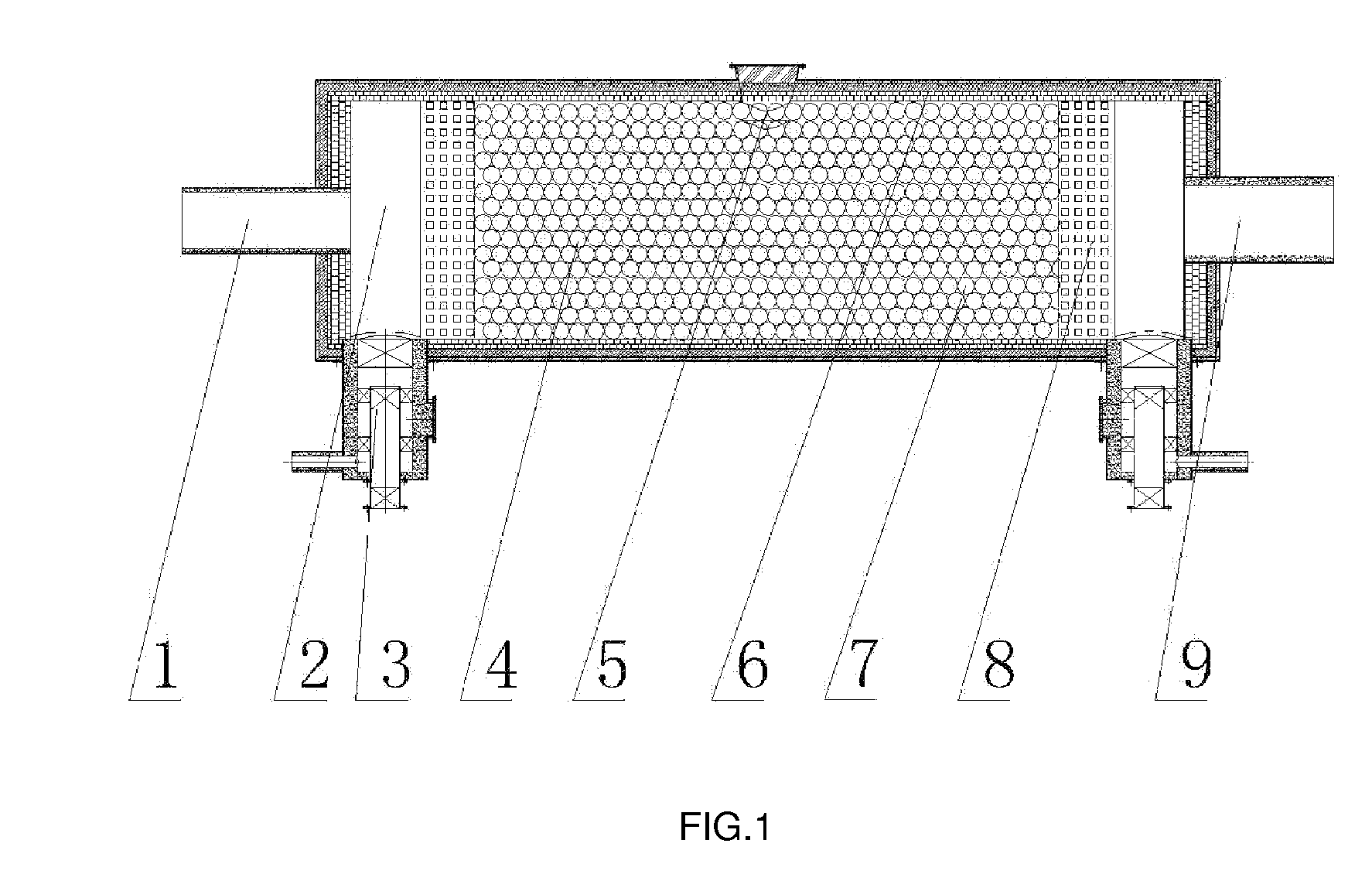

[0015]A horizontal type high-temperature hot-blast stove, it includes a furnace body (6), a ball bed (4), a cold air opening (1) and a hot air opening (9). Combustion chambers (2) are respectively set on the left side and right side in the square furnace body (6). And several square burner guns (3) are set on the bottom of the furnace body (6) which locates on the lower part of the combustion chambers (2). The cold air opening (1) is set on the left side of the furnace body (6), and the hot air opening (9) is set on the right side of the furnace body (6). The ball bed (4) consists of checker brick partition (8) and alumina balls (7) with a diameter of 10-20 mm. A manhole (5) is set on the top of the furnace body. The checker brick partition (8) and alumina balls (7) in the ball bed (4) are preheated to 1500-1550° C. The cold air is supplied to the ball bed (4) from the cold air opening. the cold air is preheated to 1250-1450° C., and then is transferred to reactor through hot air op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com