Profiles for fixing rigid plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1.1

Use of Cheap Modules

[0153]The invention is of special benefit for cheap modules because of the improved installation safety, the excellent wind resistance and the increased durability and fire safety. For demonstrating the benefits two photovoltaic cells (2*0.4 m*5.4 m) are produced (and transferred) onto two plastic films (PEN), e.g. as described in WO 98 / 13882. The PEN film is called the (plastic) cell substrate. The two PEN films (0.4 m*5.4 m), with their photovoltaic active layers, are encapsulated in a laminator according to a procedure well known in the art. The PEN films are laid in parallel in the laminator with 5 cm between them. The encapsulating layers are 5 cm wider and longer at each edge than the two PEN films and cells. These layers have therefore a length of 5.5 m and a width of 0.95 m (0.05 m+0.4 m+0.05 m+0.4 m+0.05 m). The metal plate has also a size of 0.95 m*5.5 m and may be slightly corrugated in the zones without PEN films (without cell) or provided with small ...

embodiment 2

Benefit for Uni-Solar PVL 136 Modules

[0171]Two peel and stick Uni-Solar PVL 136 modules are laminated on a 1 mm AluZink® metal sheet PVDF pre-painted with pressing rolls and installed on profiles. No water from under the modules migrates towards the modules to affect them (hydrolysis reaction). Module temperature is reduced by at least 5° C. compared to the situation of comparative embodiment 1.2.

[0172]Further, it is well known that a higher temperature during exposition to weathering negatively affects the durability. Therefore, it is expected that the durability of a photovoltaic module (photovoltaic membrane) directly installed onto an insulation panel will be lower than of a photovoltaic module glued on a ventilated metallic sheet as in this invention. The literature demonstrates surprisingly high influence. In outdoor durability of PVC-Plastisols—Journal of Coatings Technology Vol 61, N° 779, December 1989, G. Inge Bäck reports a 60% increase of durability of uninsulated panels...

embodiment 3

Benefit of the Invention for Modules Mounted on Frames

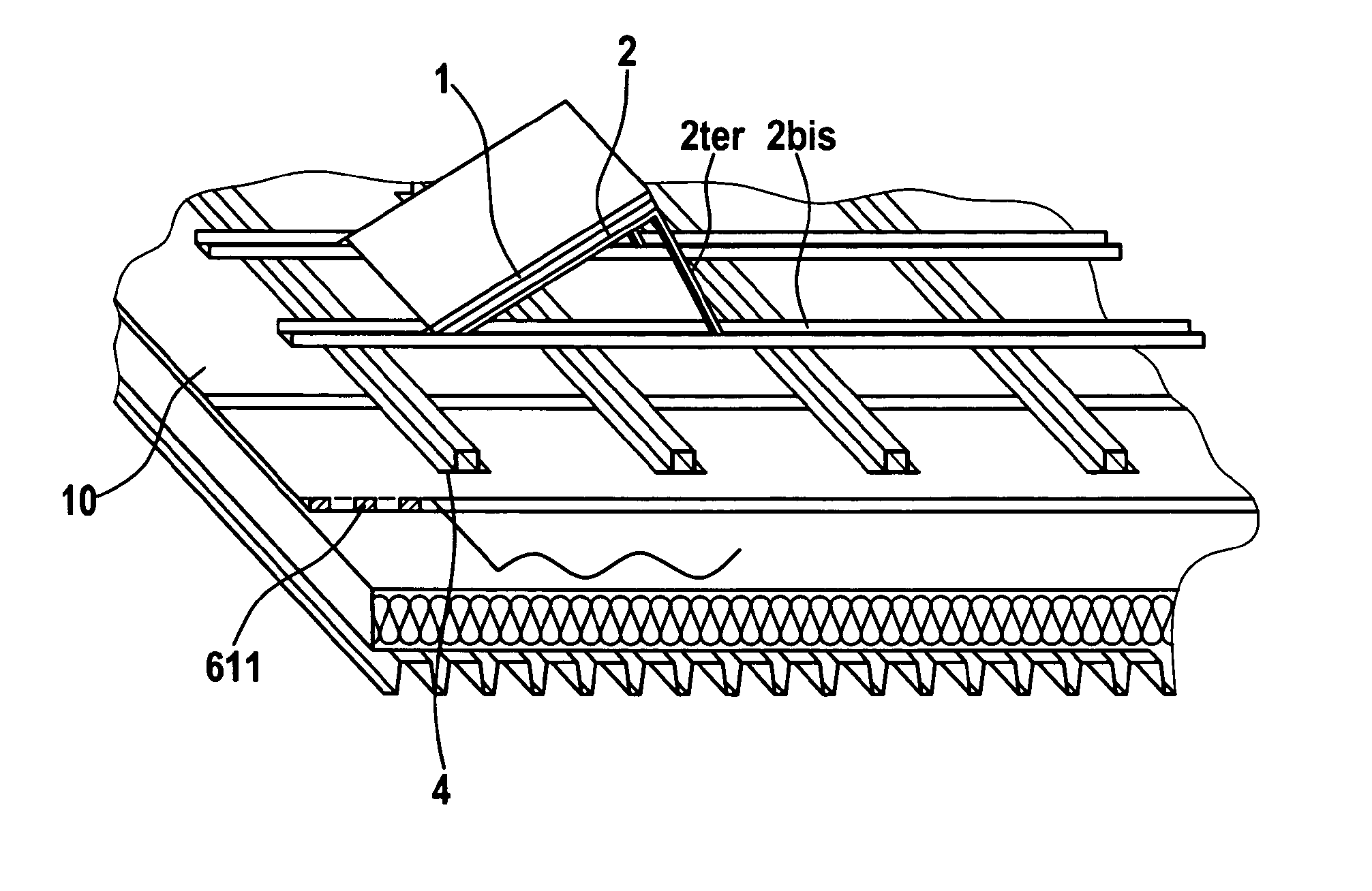

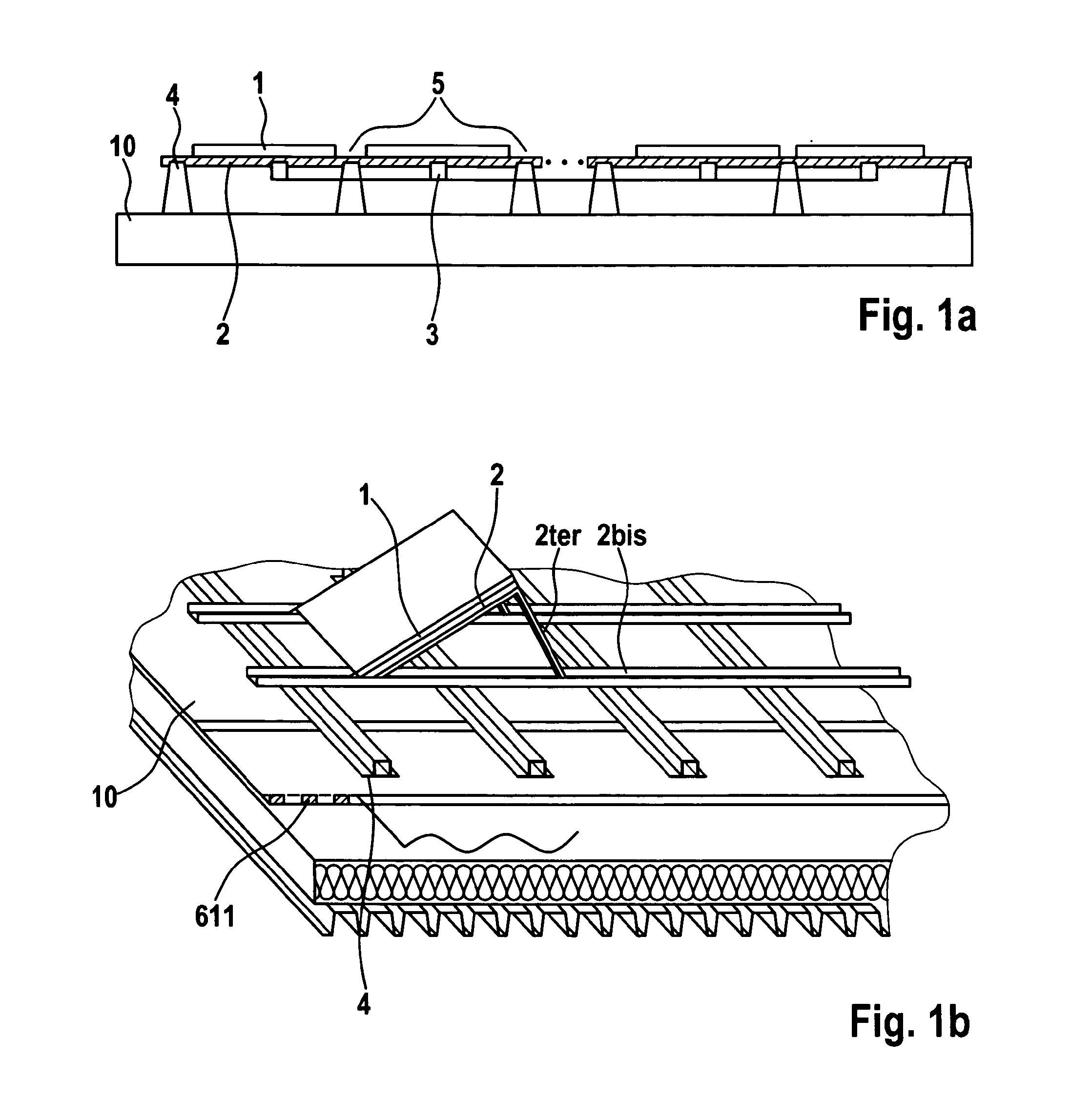

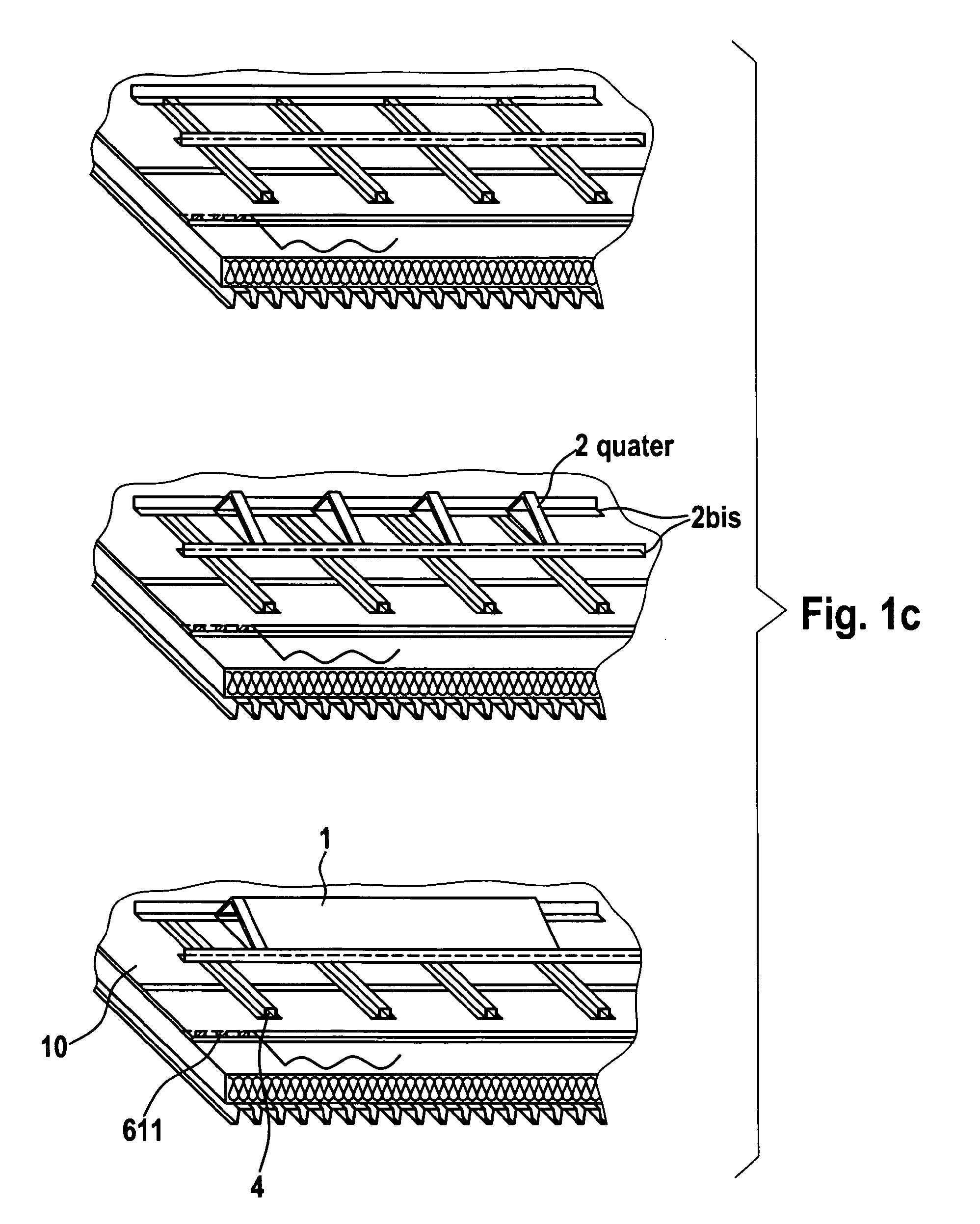

[0173]A Trina Solar Module 170 is mounted like shown on FIG. 1b (tilt angle=30°): A 1.2 mm thick, 1.6 m width Alkorplan F® 35176 waterproofing membrane (10) is first mechanically fastened (611) and welded in overlap as well known in the art, on a steeldeck “106 / 250 / 3” (0.75 mm thick and 106 mm high) with Etanco EHB DF fasteners (diameter=0.48 mm-120 mm long) and Etanco 40*82 mm2″ plates. The 100 mm thick Rockwool Taurox insulation panels are fastened with the same fasteners. Three soft profiles 4 (see FIG. 2c) with inserts 23 (2 mm thick aluminium rectangle inserts—2 cm width*2.4 cm height) are then welded in parallel on the waterproofing membrane 10 along the seams between the waterproofing membrane rolls (distance between parallel soft profiles 4=1.5 m).

[0174]Two 2 mm thick 3.5 m long Aluminium (AW 6060) U profiles 2bis (base=9 cm; height=4 cm) are then attached with screws perpendicular to the 3 profiles 4 and inserts 23. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com