System and method for operating a turbocharged engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

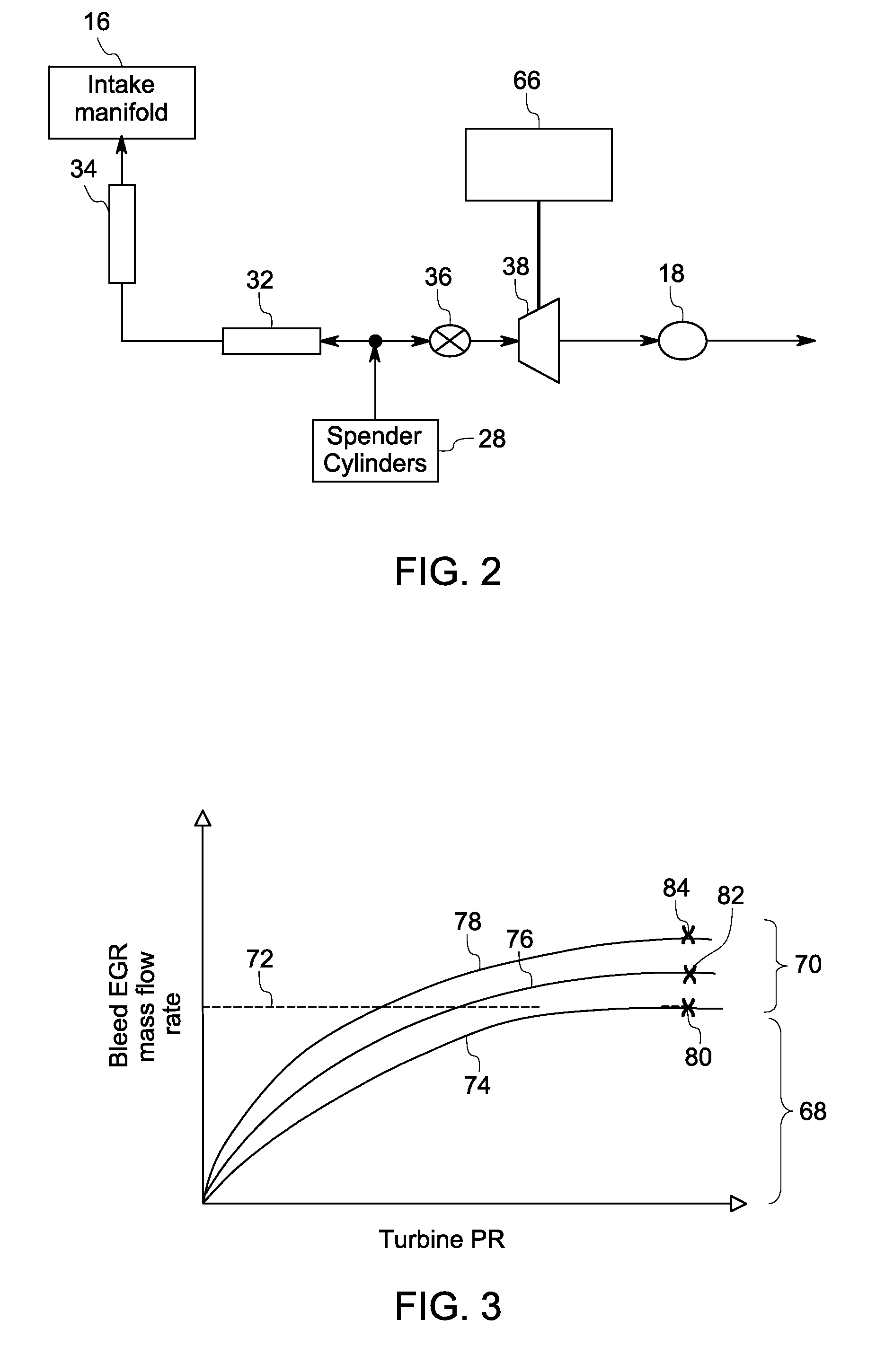

[0016]In accordance with the exemplary embodiments disclosed herein, a system and method of operating a turbocharged system is disclosed. The method includes substantially reducing specific fuel consumption and exhaust emissions of an engine by adjusting an exhaust flow from a set of predetermined cylinders among a plurality of cylinders of the engine through an exhaust gas recirculation system to an intake manifold, by adjusting a temperature of a cooler of the exhaust gas recirculation system, and by adjusting a fuel injection timing, in response to variance in a plurality of parameters. The parameters include a quantity of exhaust emissions, a maximum in-cylinder pressure of the engine, an engine load, an engine notch, engine speed, a percentage of exhaust gas recirculation through the exhaust gas recirculation system, a sulfur content in a fuel, a fuel injection pressure, or combinations of the parameters thereof.

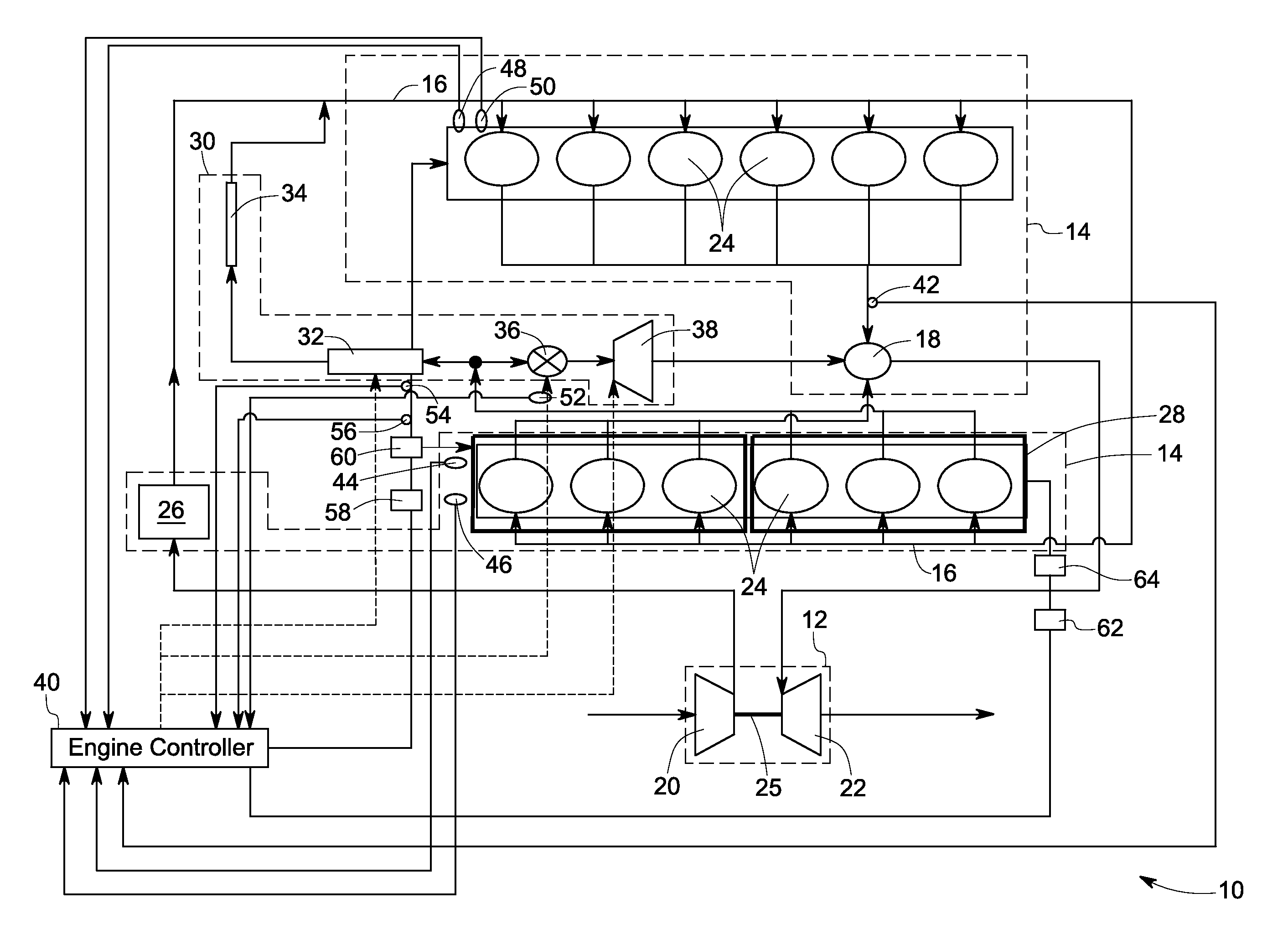

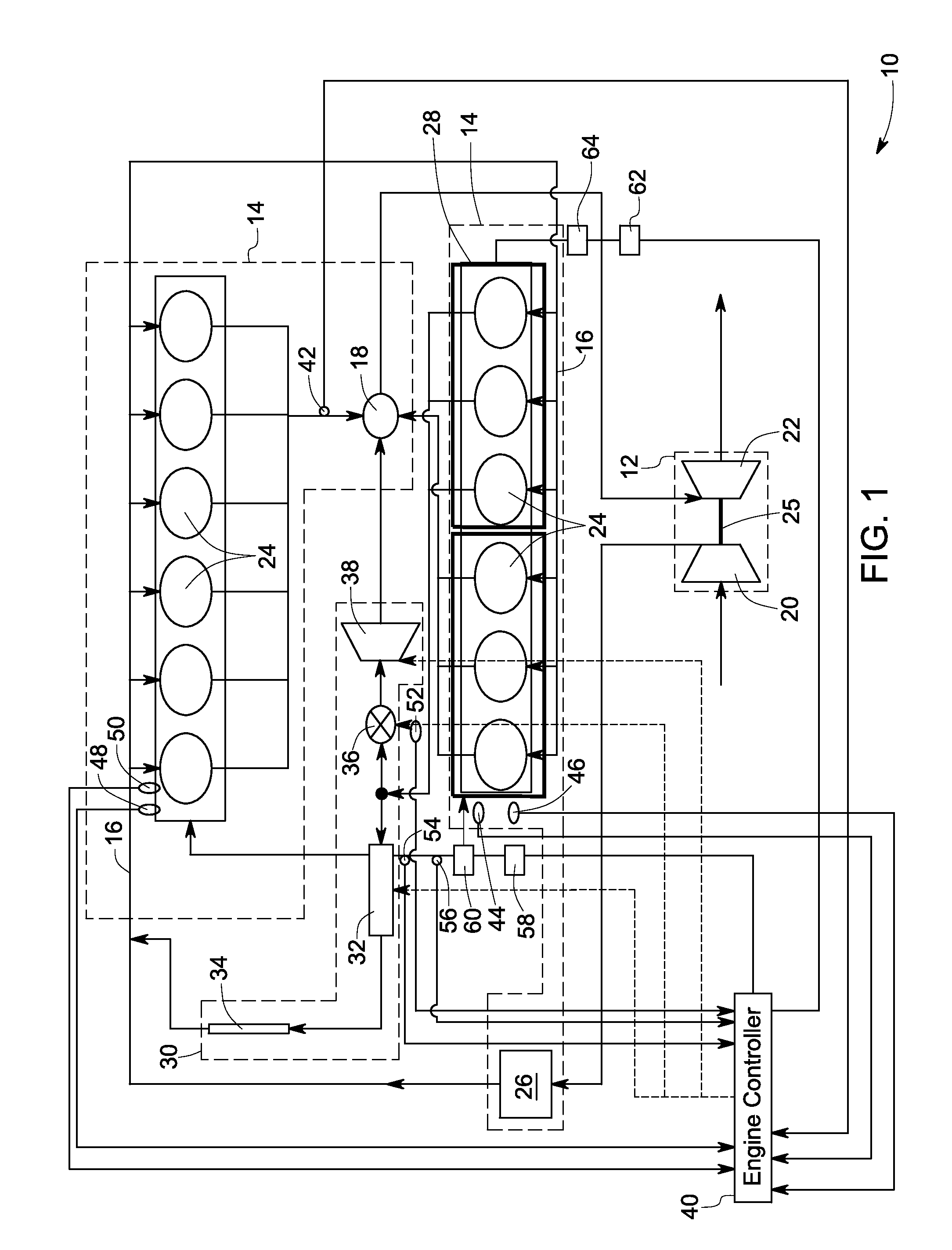

[0017]Referring to FIG. 1, a turbocharged engine system 10 having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com