Liquid metal thermal storage system

a thermal storage system and metal technology, applied in the direction of indirect heat exchangers, solar heat storage, lighting and heating apparatus, etc., can solve the problems of storing high temperature gas as a realistic energy storage option, restricting the heat flow into and out of storage materials, and limiting the use of this type of latent heat storage system, etc., to achieve excellent heat transfer within the metal, reduce the conversion efficiency, and high thermal conductivity of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The embodiments of the invention are illustrated in the context of a Brayton cycle solar thermal electric power plant. The skilled artisan will readily appreciate, however that the materials and methods disclosed herein will have application in a number of other contexts where high temperature thermal storage is desirable.

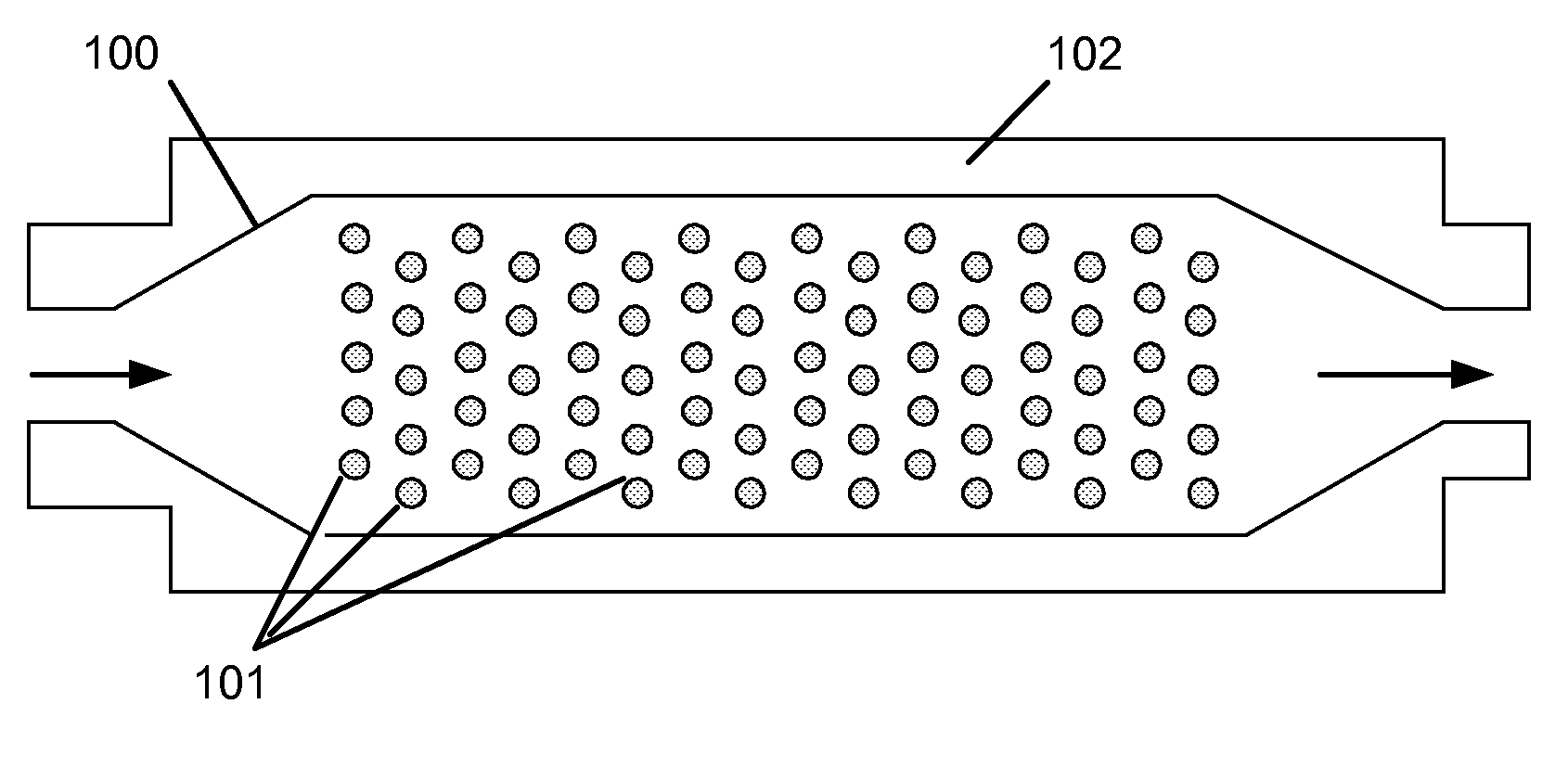

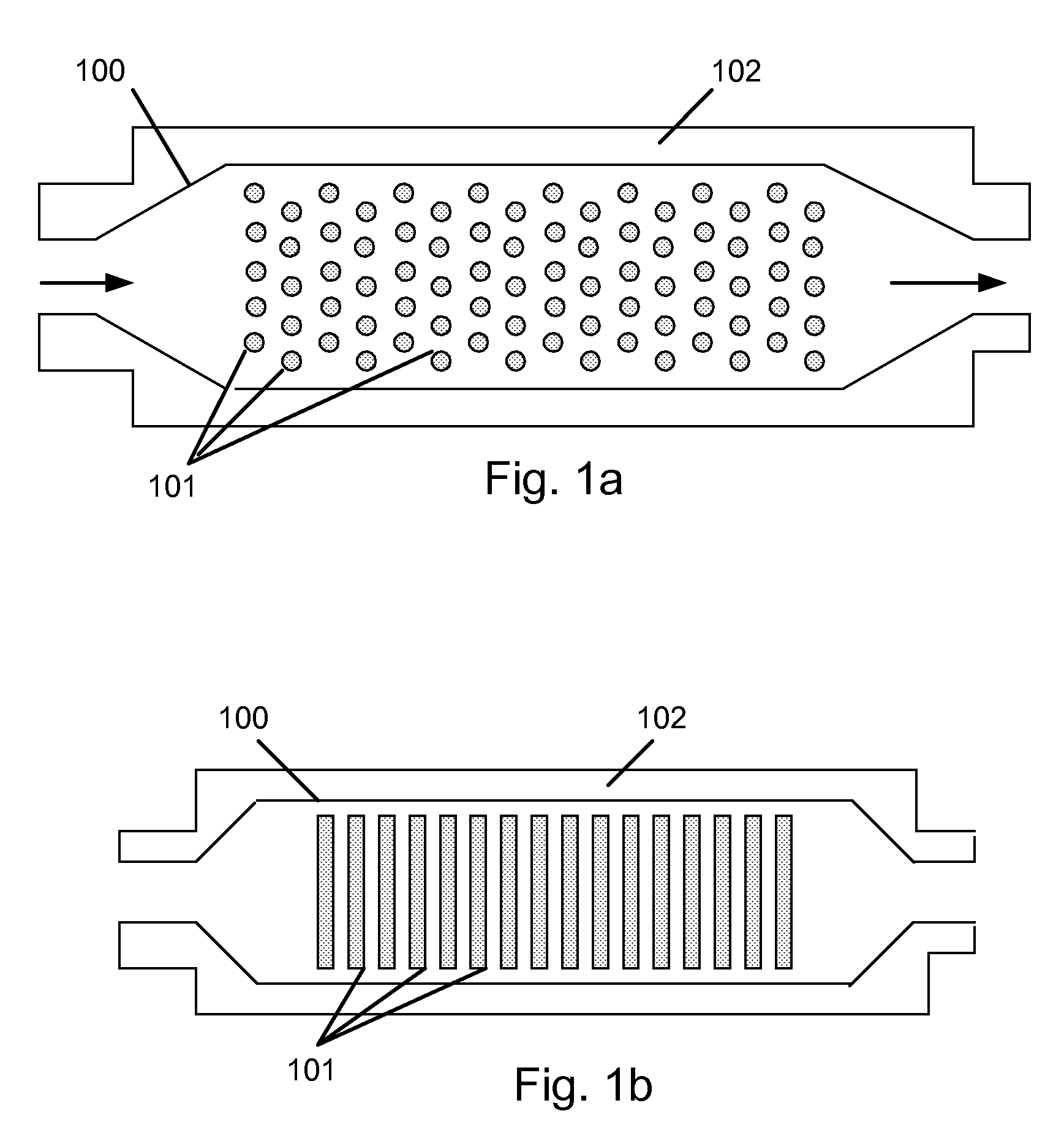

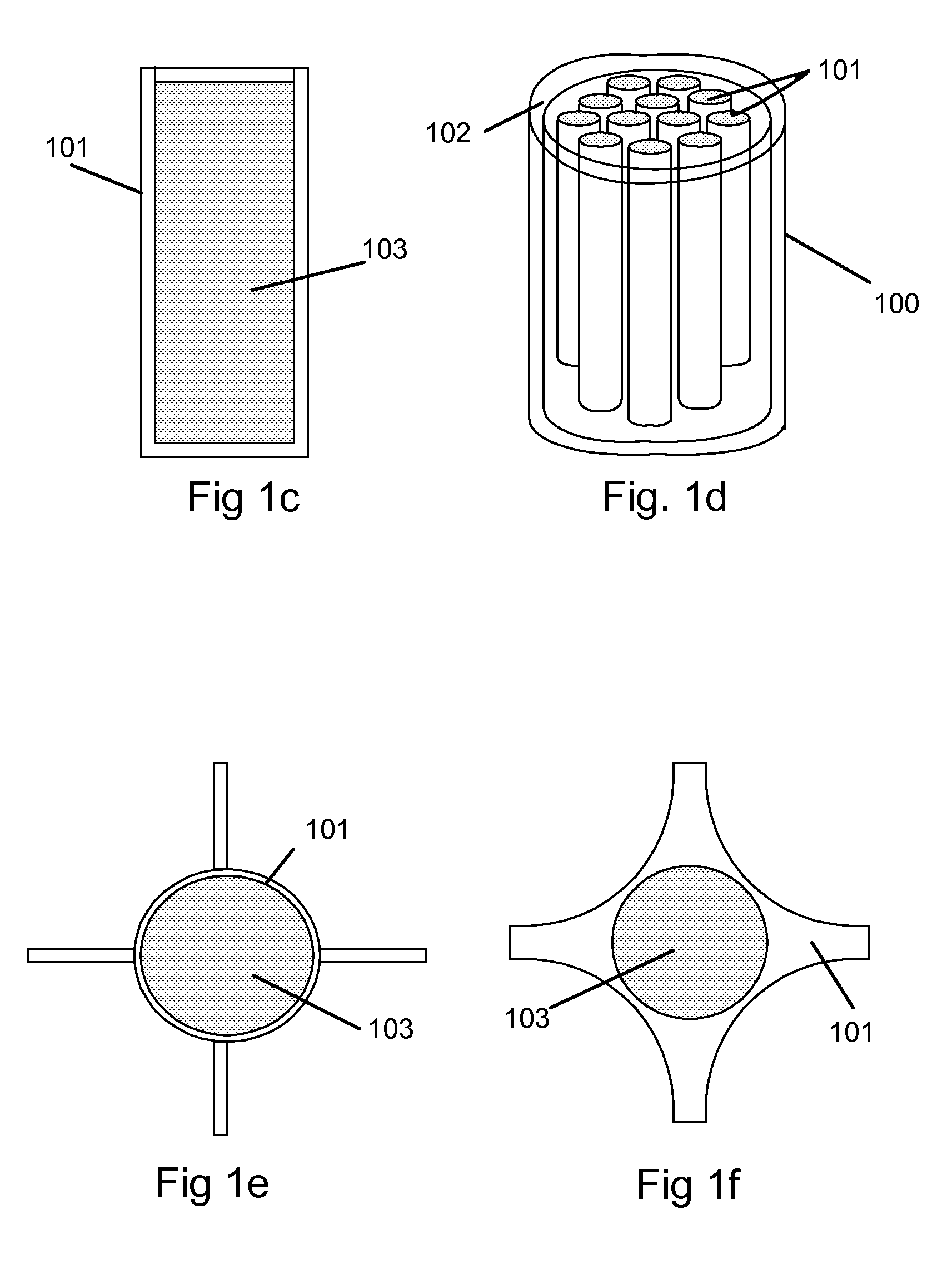

[0031]One embodiment of the invention, also know as a Liquid Metal Thermal Storage system (LIMETS) consists of substantially four items ; the metal or metal alloy thermal storage material, the tubes or a compartment containing the metal or metal alloy, the insulated cavity enclosing the tubes, and the heat transfer medium (gas). FIG. 1a is a top view of a schematic drawing of the system showing the insulated cavity 100, the ceramic or clad graphite tubes 101 containing the metal or metal alloy and the insulated container 102. FIG. 1b is a side view of the same components. FIG. 1c is a cross sectional view of the tube and metal showing one tube 101 and metal 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com