Fibrous surface structure containing active ingredients with controlled release of active ingredients, use thereof and method for the production thereof

a technology of fibrous and surface structure, which is applied in the field of fibrous surface structure containing, can solve the problems of controlling the release of formulated active ingredients, and achieve the effect of reducing the risk of cancer and affecting the survival rate of cancer patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Production and Properties of the Composite Fibers from PVP and Epoxiconazole

[0322]To produce composite fibers, polymer solutions were produced from poly(1-vinyl-2-pyrrolidinone) Kollidon K-90 (PVP) (Mw=1 100 000 g / mol, Tg=180° C., BASF SE) and epoxiconazole fungicide (1-{[3-(2-chlorophenyl)-2-(4-fluorophenyl)oxiran-2-yl]methyl}-1H-1,2,4-triazole) in an ethanol / water mixture (90:10) and spun to fibers. This involves spinning the solutions with a spinning system under voltages between 35 and 45 kV.

[0323]The starting weights are listed in the following table:

Activeingredientcontent, % byMaterialMass, gweightEthanol7.104Water0.998PVP0.486Epoxiconazole0.04869.1″0.097216.7″0.14623.1″0.19428.6″0.24333.3

The concentration figures of the epoxiconazole active ingredient are based on total solids (PVP+active ingredient). The concentration of the carrier polymer is based on the total mass of solvent and polymer before the addition of the active ingredient.

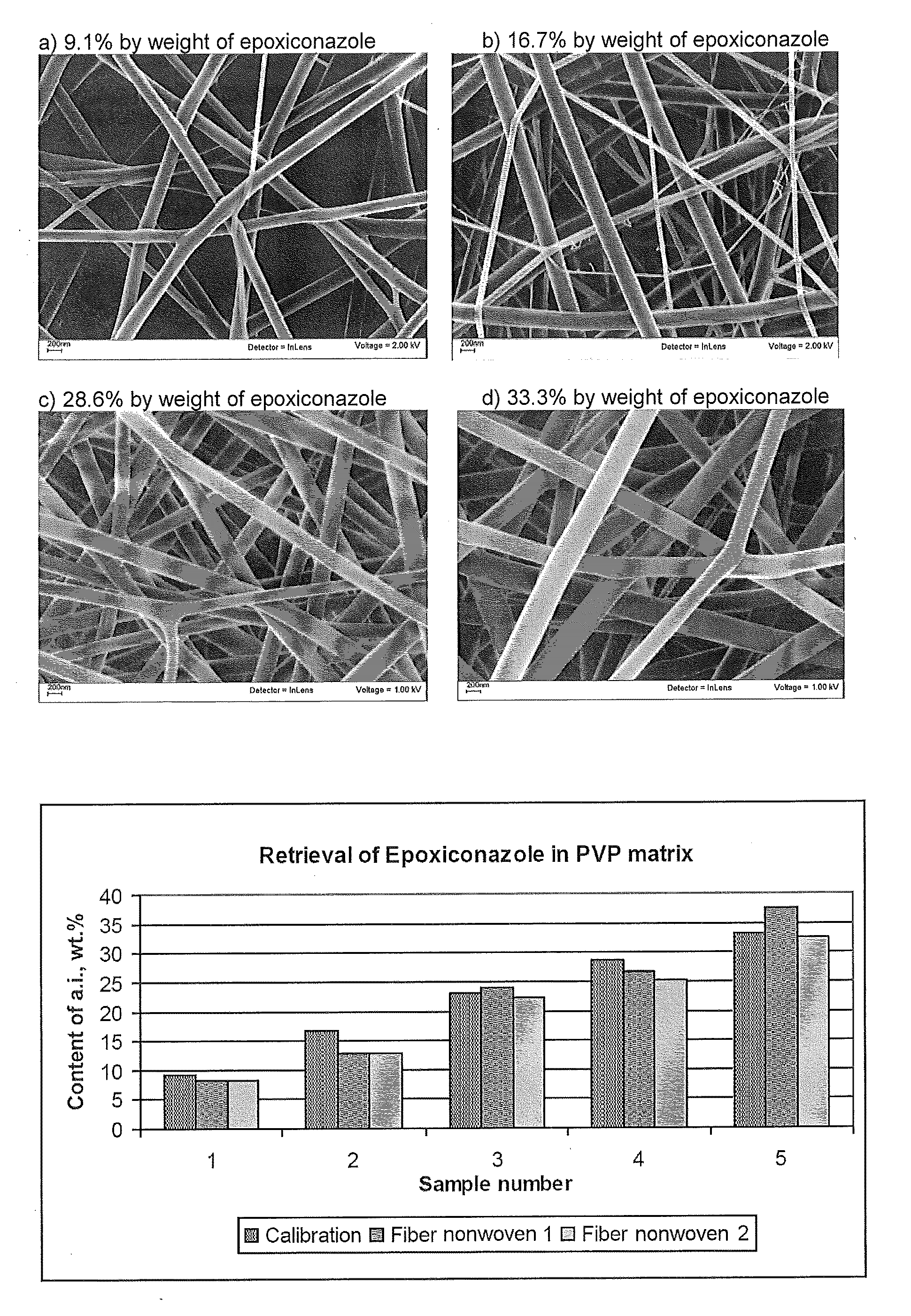

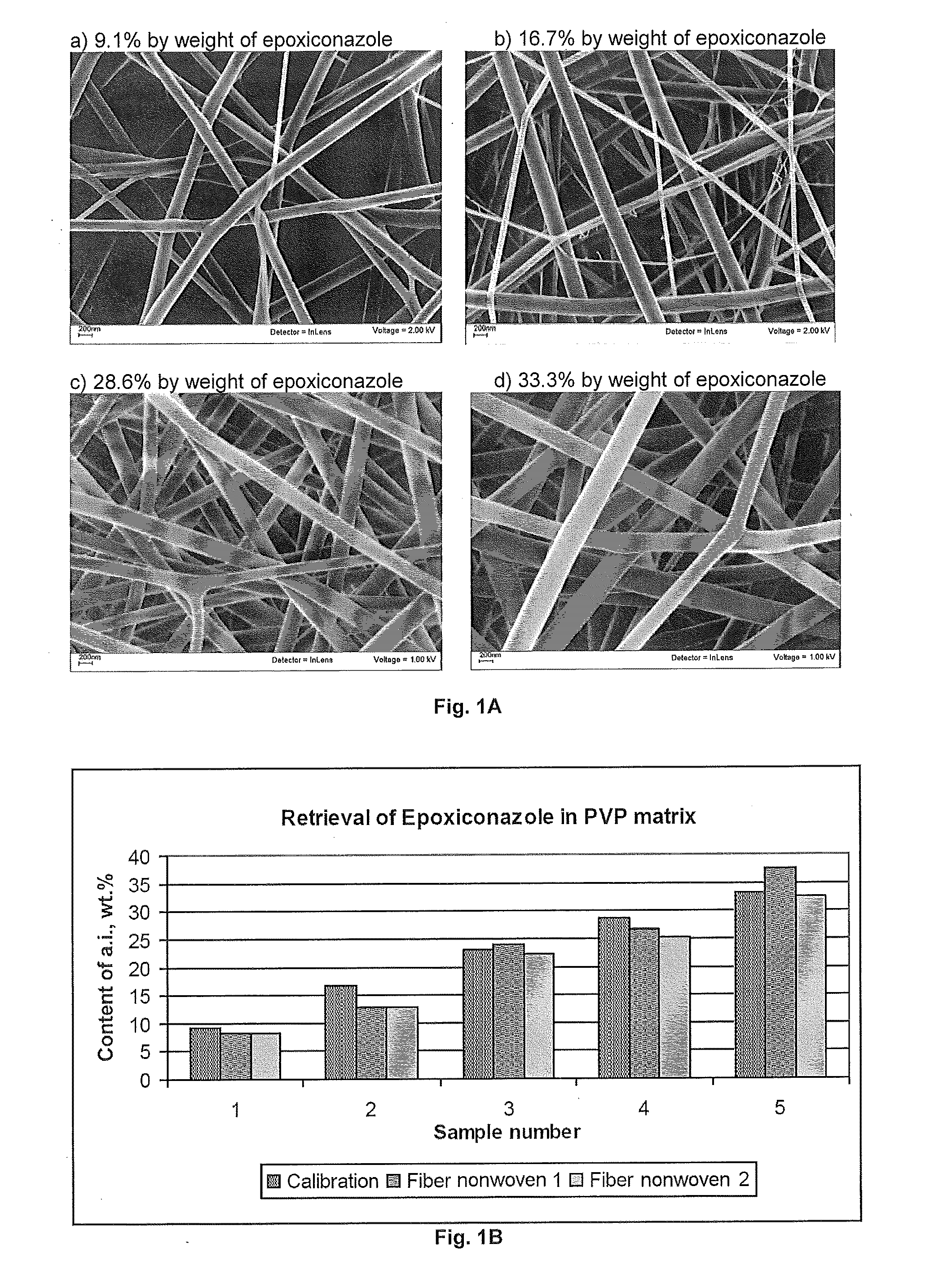

[0324]FIG. 1A shows the fiber morphology...

example 2

Production and Properties of the Composite Fibers Formed by PVP and Beta-carotene.

[0333]β-Carotene is used to color fatty foods such as butter, margarine, cheese, mayonnaise and—in water-dispersible form—also water-containing foods, for example fruit drinks, puddings, confectionary. β-carotene is also used as a dye for cosmetics and as an animal feed additive. To produce composite fibers, polymer solutions were produced from poly(1-vinyl-2-pyrrolidinone) Kollidon K-90 (PVP) (Mw=1 100 000 g / mol, Tg=180° C., BASF SE) and the β-carotene dye in chloroform and spun to fibers. For this purpose, the solutions were spun with a syringe system under voltages between 40 and 45 kV. In addition, 0.5% by weight, based on the overall formulation, of benzyltributylammonium bromide was added thereto in order to increase the electrical conductivity of the solution. This has a positive effect on the fiber morphology and diameter distribution: fewer beads form and the fiber diameter distribution become...

example 3

Production and Properties of the Composite Fibers Formed by PMMA and Epoxiconazole

[0345]In order to further illustrate the broad applicability of the method, composite fibers were produced from poly(methyl methacrylate) and epoxiconazole fungicide.

[0346]To produce composite fibers, polymer solutions were produced from poly(methyl methacrylate) Plexiglas® (PMMA) (Mw=430 000 g / mol, Tg=110° C. (Iso 11357)) and epoxiconazole fungicide (1-{[3-(2-chlorophenyl)-2-(4-fluorophenyl)oxiran-2-yl]methyl}-1H-1,2,4-triazole) in an ethanol / chloroform mixture (6:11) and spun to fibers. For this purpose, the solutions were spun with a syringe system under voltages between 40 and 45 kV.

[0347]The starting weights are listed in the following table:

Active ingredientcontent, % byMaterialMass, gweightEthanol5.53Chloroform10.14PMMA1.00Epoxiconazole0.1110″0.2520″0.4330″1.0050

[0348]The concentration figures for the epoxiconazole active ingredient are based on total solids (PMMA+active ingredient). The concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com