Grain or legume having increased content of functional component and a manufacturing method thereof

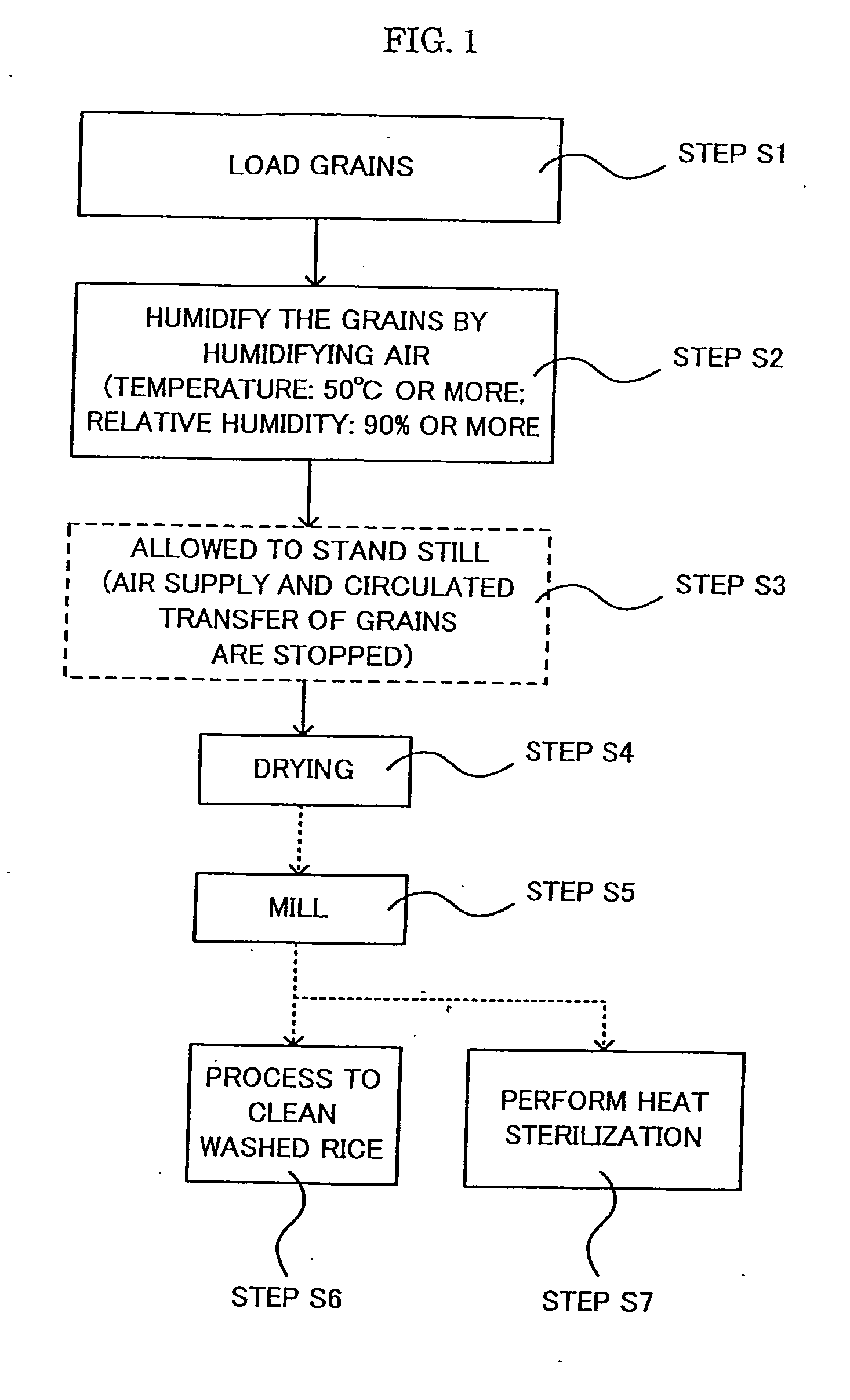

a technology of functional components and grains, which is applied in the field of grains or legumes having increased content of functional components and a manufacturing method thereof, can solve the problems of method problems, damage such as rice cracking, and the taste of brown rice is likely to deteriorate, so as to prevent damage to grains, and increase the moisture content of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

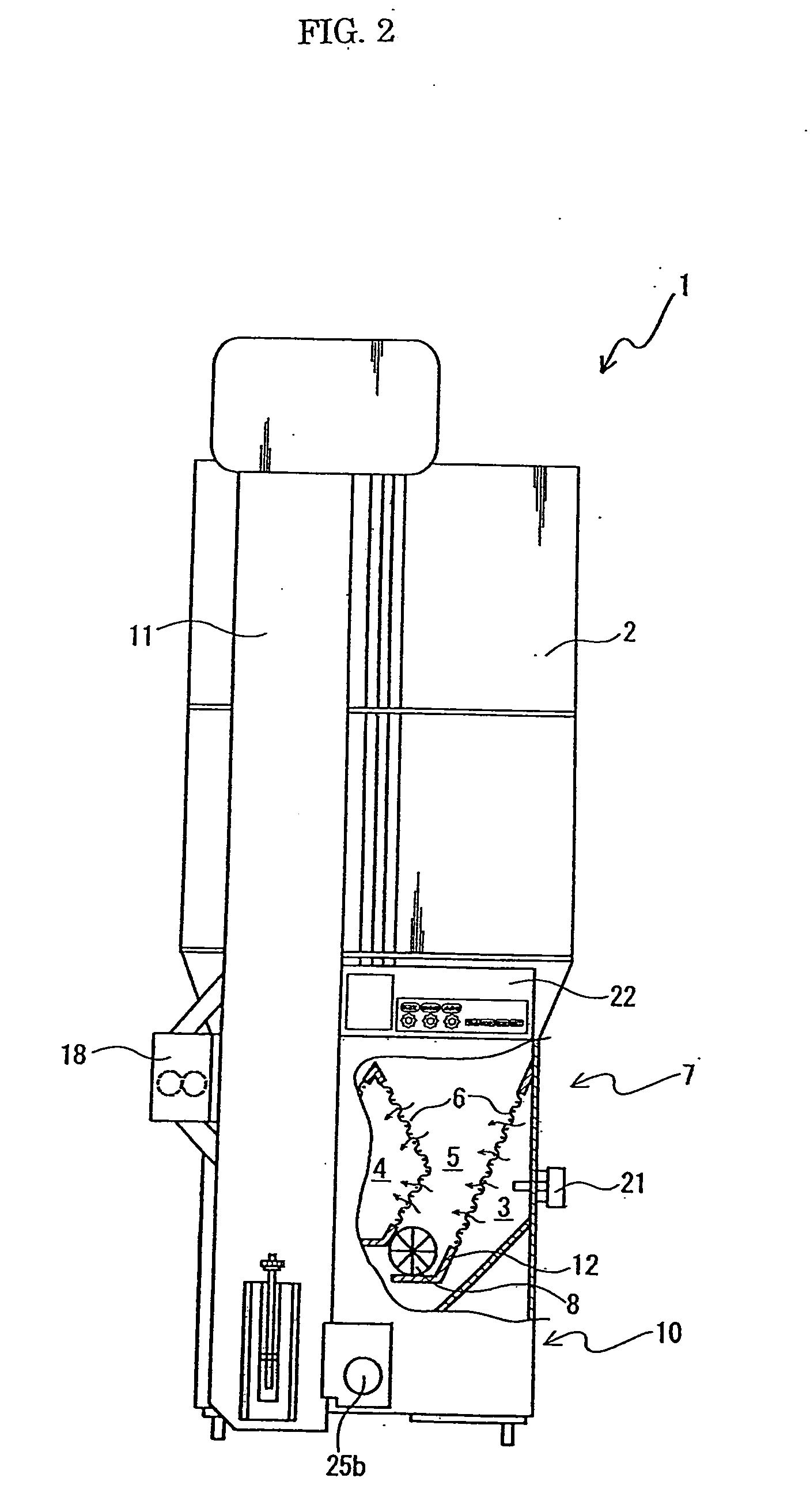

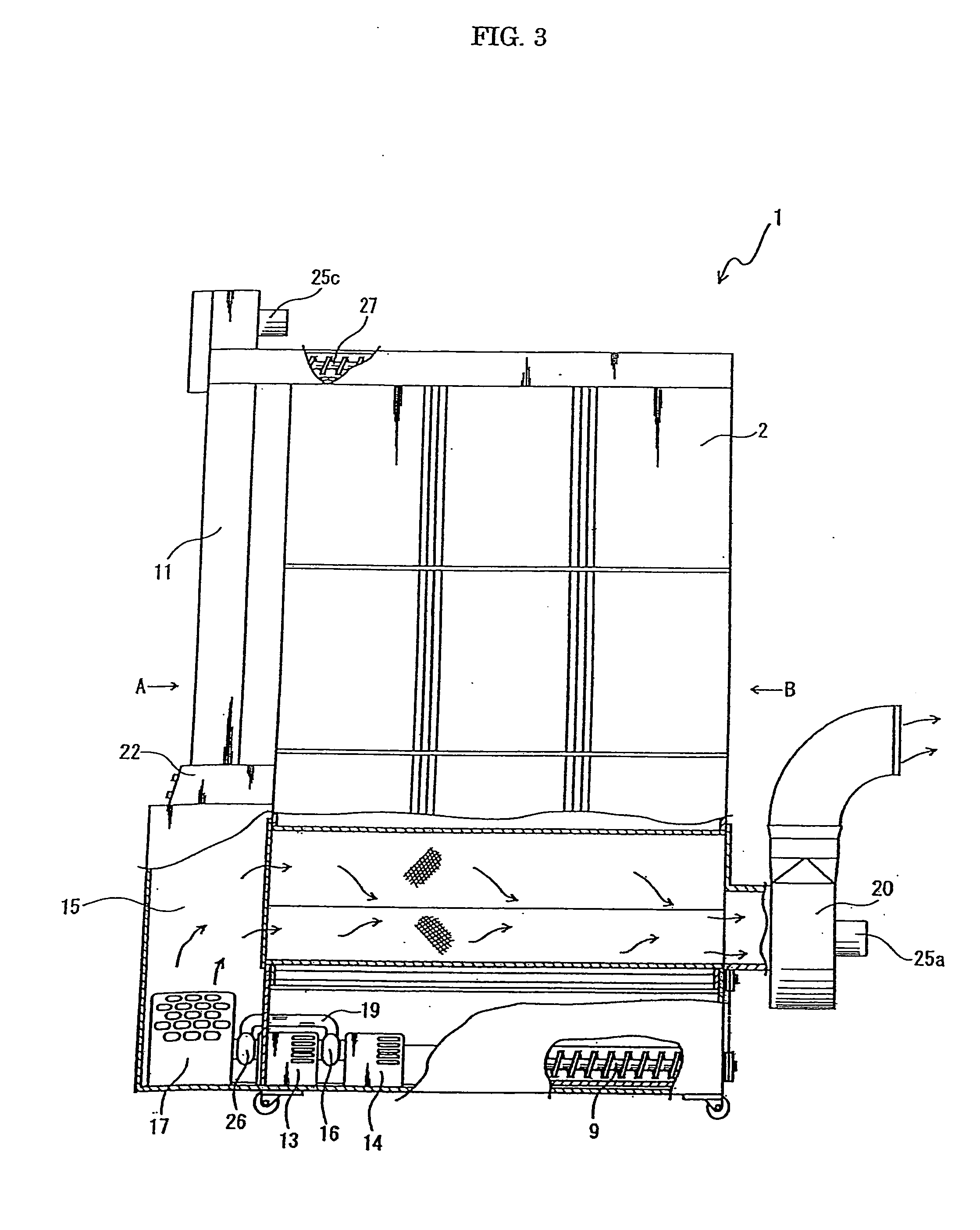

[0089]As an example of the present invention, “Akitakomachi” (brand name of rice, produced in Akita prefecture, Japan, in 2006) was processed by the manufacturing method of the present invention. Using the humidification / dehydration apparatus 1, brown rice of “Akitakomachi” was humidified at a humidification rate of 0.3% / hour or less (a moisture increasing rate of 0.3% or less per hour) such that the moisture content thereof might not exceed 18.5%. In the humidification operation, the relative humidity of the humidifying air was set at 90% or more. The temperature of the humidifying air was maintained at room temperature for one hour from initiation of humidification operation, then increased to 20° C. for the following one hour, and thereafter increased at a rate of 5° C. per hour like 25° C., 30° C., 35° C. and 40° C. In this way, the temperature of the humidifying air reached 40° C. 5 hours after initiation of the humidification operation. Thereafter, the temperature was raised a...

example 2

[0094]As an example of the present invention, foxtail millet with husk was processed by the manufacturing method of the present invention. Foxtail millet was humidified by the humidification / dehydration apparatus 1 such that the moisture content thereof might not exceed 18.5%. In the humidification operation, the humidifying air having a relative humidity of 90% or more and a temperature of 60° C. was applied for 4 hours for humidification. In this processing for foxtail millet, after completion of the humidification operation, the stationary step was not performed and directly subjected to the dehydration operation. In the dehydration operation, dry air having a relative humidity of 30% and a temperature of 45° C. was applied for 3 hours from initiation of the dehydration operation. Thereafter, the temperature of the dry air was gradually decreased finally to room temperature. In this way, foxtail millet was dried until the moisture content thereof became about 13% to obtain foxtai...

example 3

[0097]As an example of the present invention, millet with husk was processed by the manufacturing method of the present invention. Millet was humidified by the humidification / dehydration apparatus 1 such that the moisture content thereof might not exceed 18.5%. In the humidification operation, the humidifying air having a relative humidity of 90% or more and a temperature of 60° C. was applied for 4 hours for humidification. In this processing for millet, after completion of the humidification operation, millet was not subjected to the stationary operation and directly subjected to the dehydration operation. In the dehydration operation, dry air having a relative humidity of 30% and a temperature of 45° C. was applied for 3 hours from initiation of the dehydration process. Thereafter, the temperature of the dry air was gradually decreased finally to room temperature. In this way, millet was dried until the moisture content thereof became about 13% to obtain millet having an increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com