Method for Storing Target Comprising Rare Earth Metal or Oxide Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

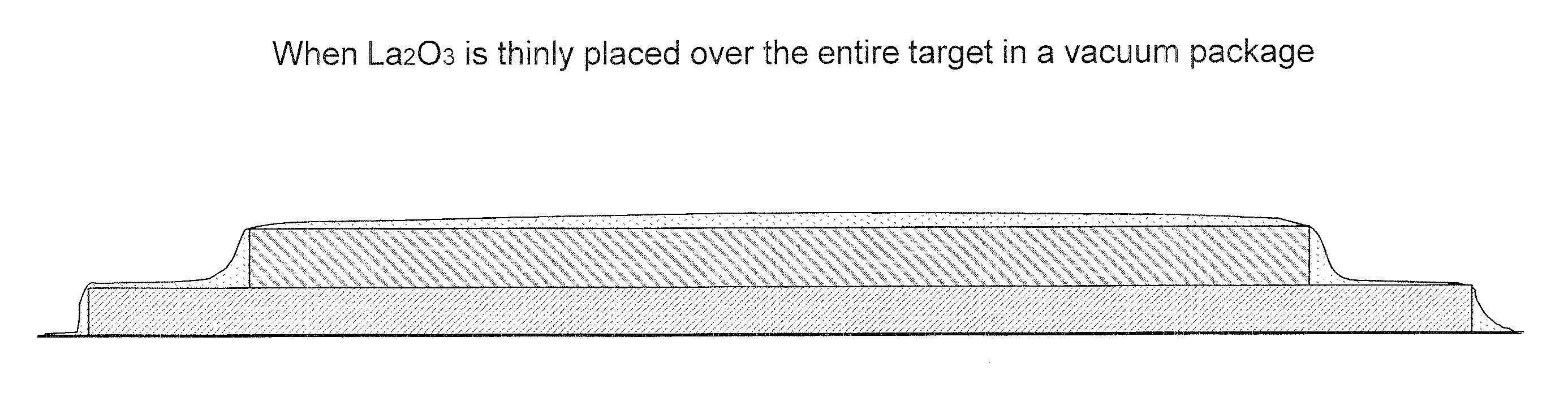

[0058]This is an example where the surface and side face of a La target are thinly coated with La oxide powder and vacuum packing is performed thereto. A specific example is shown in FIG. 1.

[0059]As shown in FIG. 1, as a result of a lanthanum oxide layer existing between the vacuum-packing film and the La target, the lanthanum oxide powder absorbs the moisture remaining inside the vacuum package and the moisture that penetrates the film and is fixed as lanthanum hydroxide. Thus, this is effective in preventing the phenomenon where the La target surface reacts with moisture to become hydroxide and be pulverized.

example 2

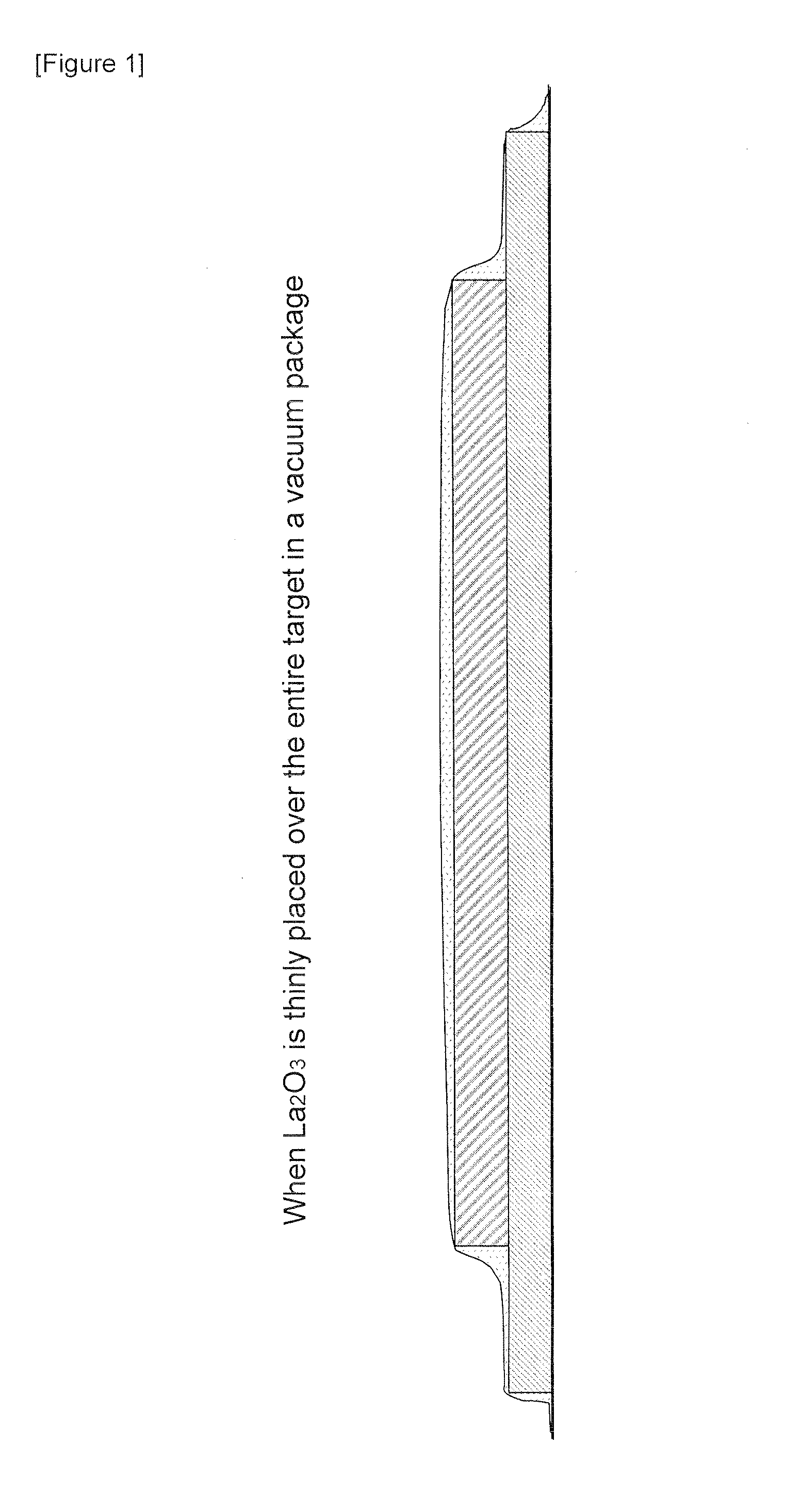

[0060]This is an example where La oxide powder (as with a silica gel bag) is placed in a space due to the unevenness with BP and vacuum packing is performed thereto. A specific example is shown in FIG. 2.

[0061]As shown in FIG. 2, since La oxide absorbs the moisture in the slight space remaining in the vacuum package and is fixed as lanthanum hydroxide. Thus, this is effective in preventing the phenomenon where the La target reacts with moisture to become of hydroxide and be pulverized.

example 3

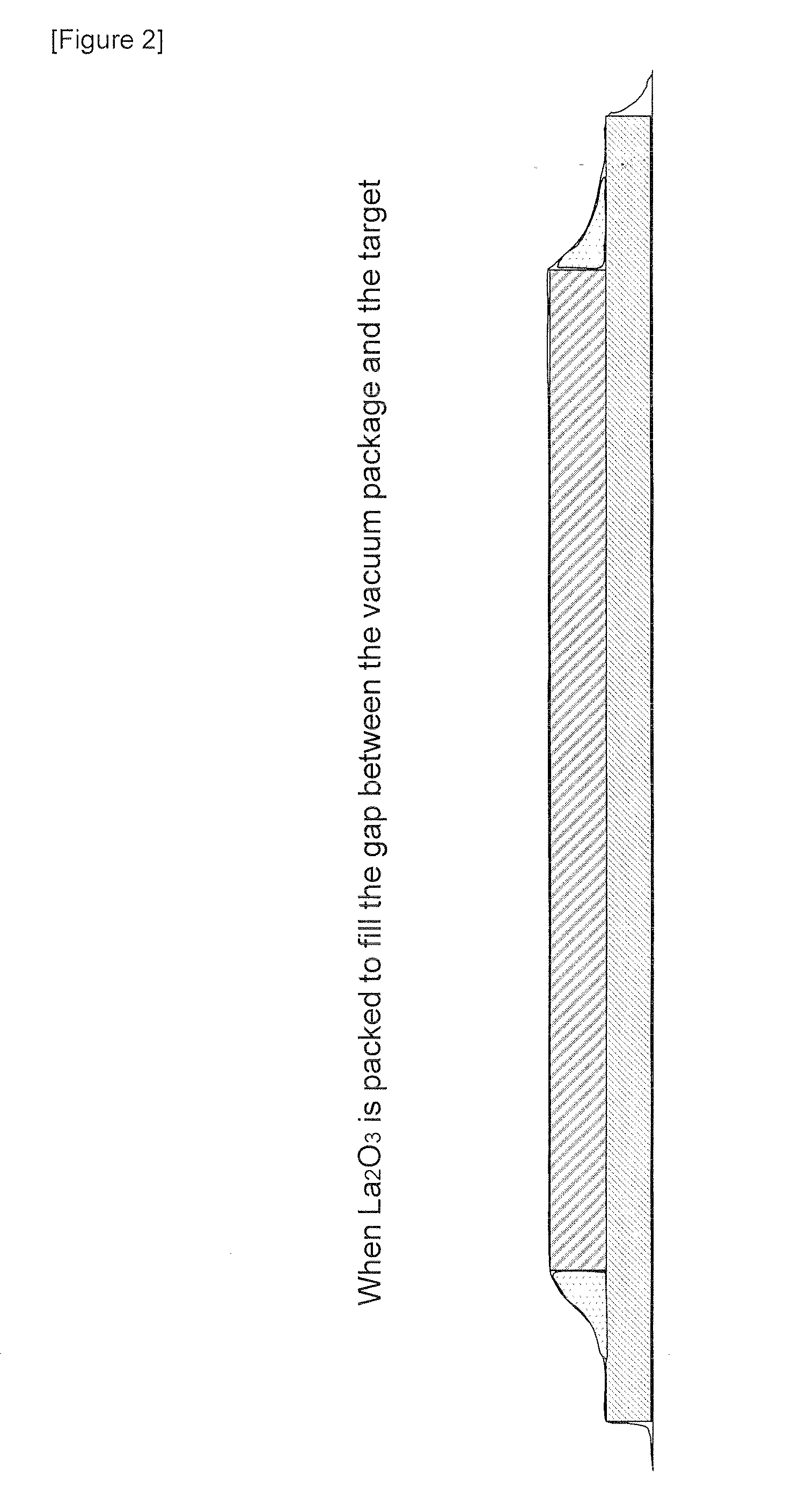

[0062]This is an example where a La oxide target is placed in a metallic container, La oxide powder is filled around the periphery of the La target, ambient air is once replaced with argon having a dew point or −80° C. or less, and vacuum sealing is subsequently performed thereto. A specific example is shown in FIG. 3.

[0063]As shown in FIG. 3, lanthanum oxide absorbs the moisture remaining after the vacuuming and is fixed as lanthanum hydroxide. Thus, this is effective in preventing the phenomenon where La reacts with moisture to become hydroxide and be pulverized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dew point | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap