Device for the metered addition of fuel

a technology of fuel addition and metering device, which is applied in the direction of auxillary pretreatment, separation process, filtration separation, etc., can solve the problems of burning off of soot stored in the particle filter, and achieve the effect of reducing pressure peaks, quick detection, and lessening the danger of damage to the sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

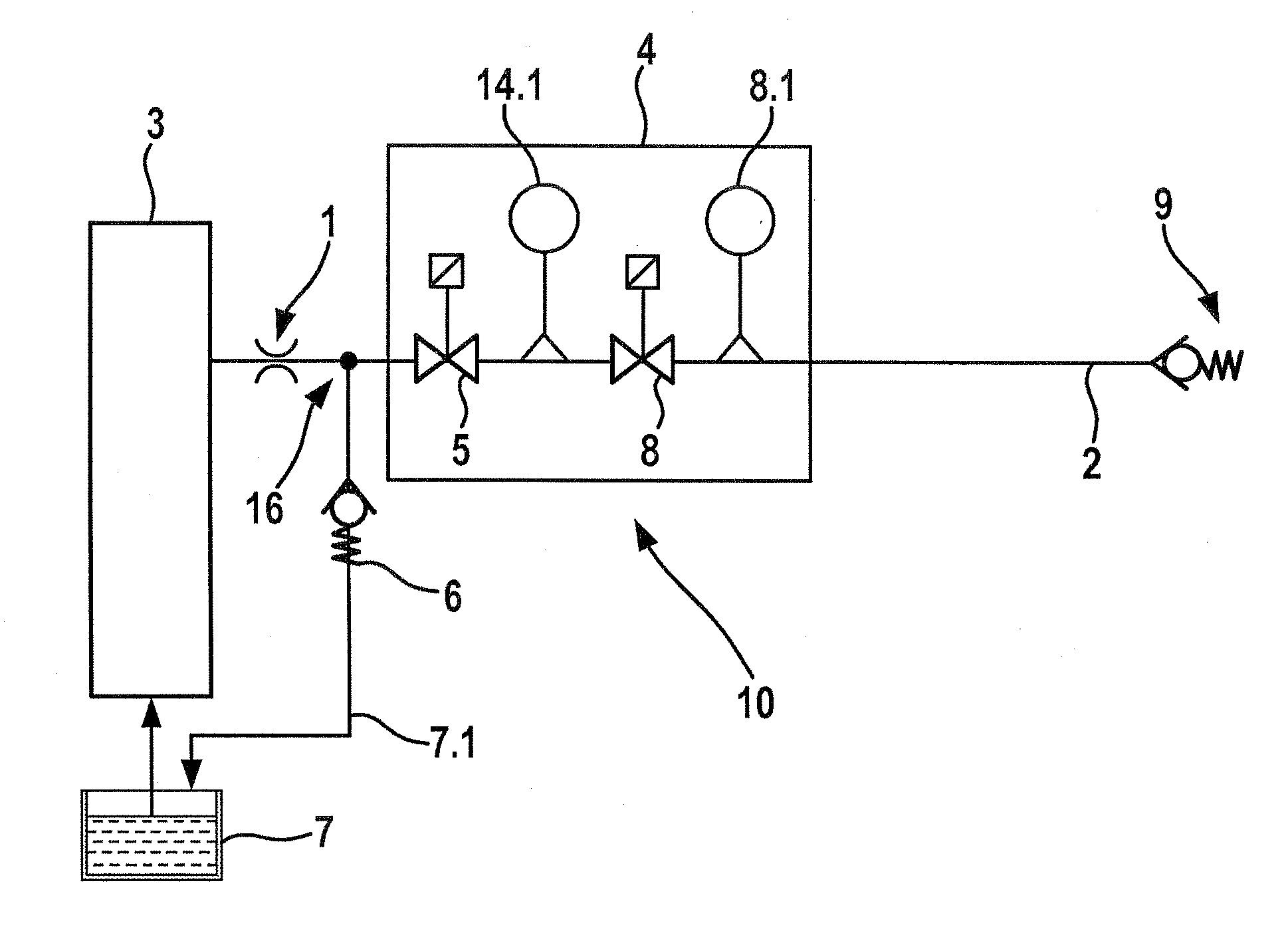

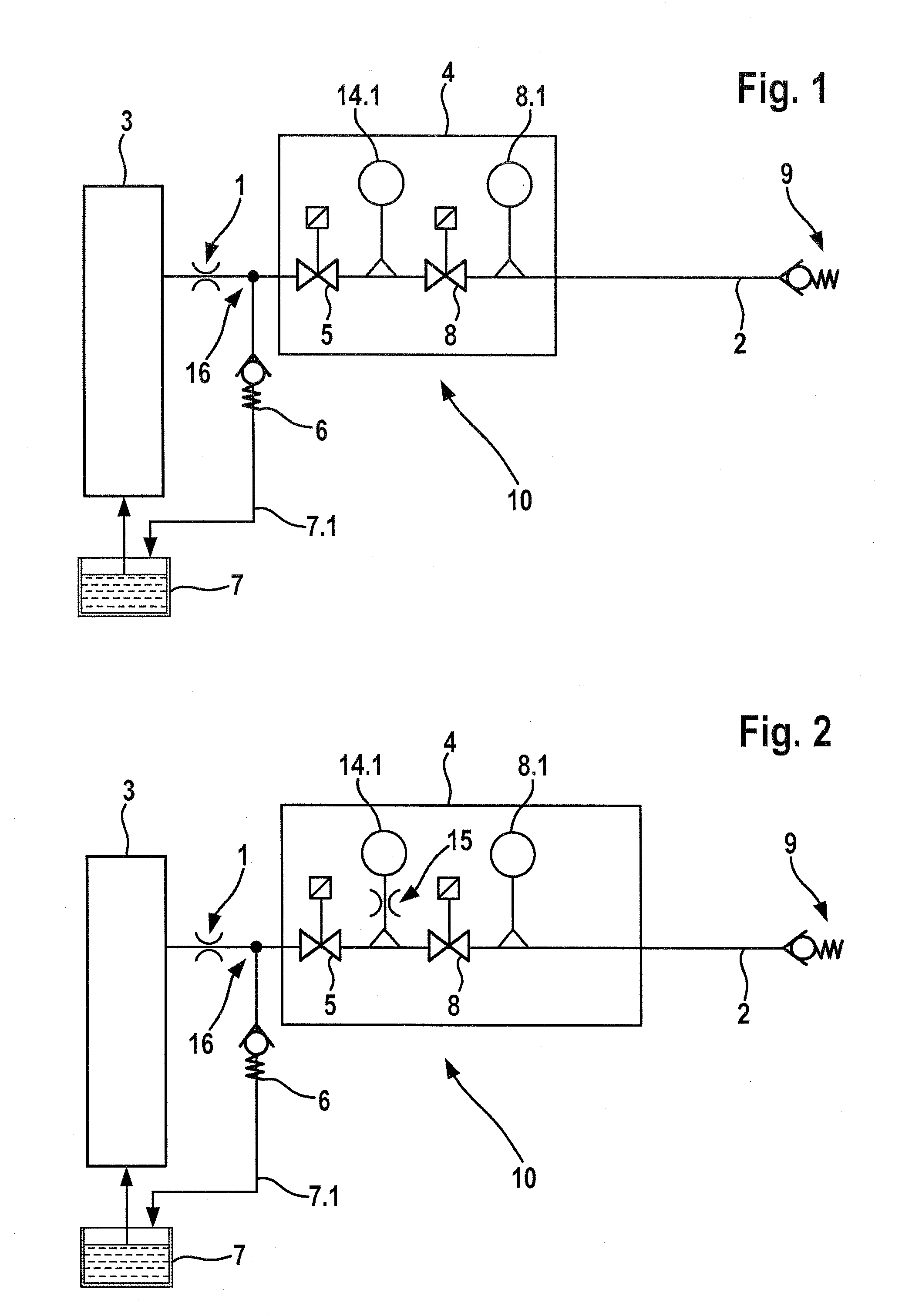

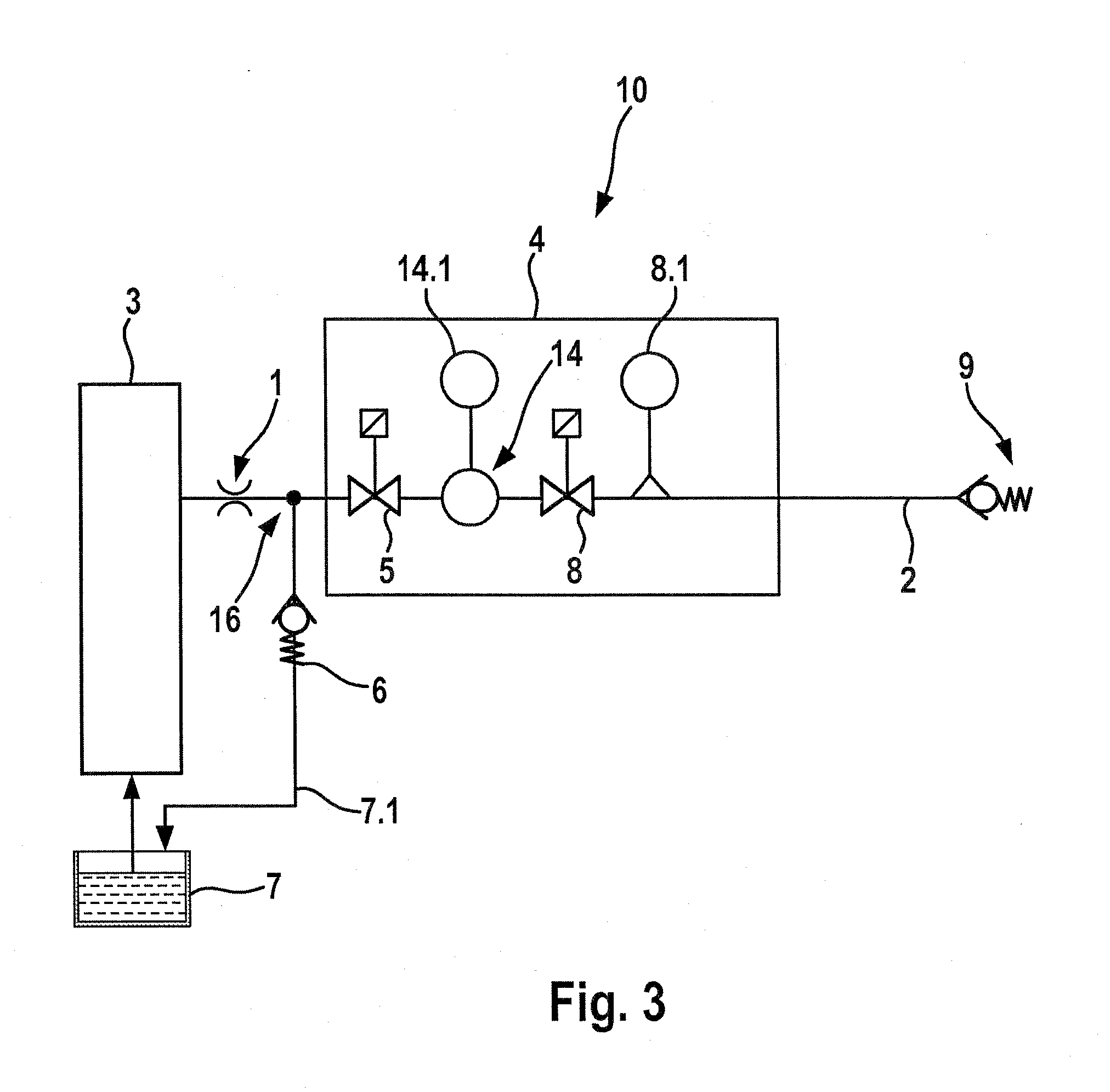

[0014]It can be seen from the view in FIG. 1 that the fuel supply to a metering device 10 is effected via a pickup point at a low-pressure circuit 3 of a fuel injection system, not further shown in FIG. 1, of an internal combustion system of the vehicle. Via a throttle restriction 1 provided in a fuel inlet 16, fuel flows to a metering unit 4, which in FIGS. 1-3 is represented by a rectangular outline and is accommodated in a housing part, not shown in detail in the drawing.

[0015]In regeneration pauses, a closing valve 5 provided downstream of the throttle restriction 1 interrupts the inflow of fuel, especially diesel fuel, to the metering unit 4. With the closing valve 5 closed, the entire fuel volume flows back into a tank 7, via an overflow valve 6, embodied for example as a check valve. The overflow valve 6 is provided in a return line 7.1, which is connected between the throttle restriction 1 and the metering unit 4 to the fuel inlet 16 and which discharges into the tank 7.

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com