Carbon nanotube vacuum gauges with wide-dynamic range and processes thereof

a vacuum gauge and carbon nanotube technology, applied in the direction of fluid pressure measurement, instruments, measurement devices, etc., can solve the problems of inability to obtain a wide dynamic range with these transducers, and inability to integrate with many vacuum-encased si-based micro-cavity applications, etc., to achieve substantial pressure sensitivity, reduce thermal conduction dimensionality, and high temperature coefficient of resistivity ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

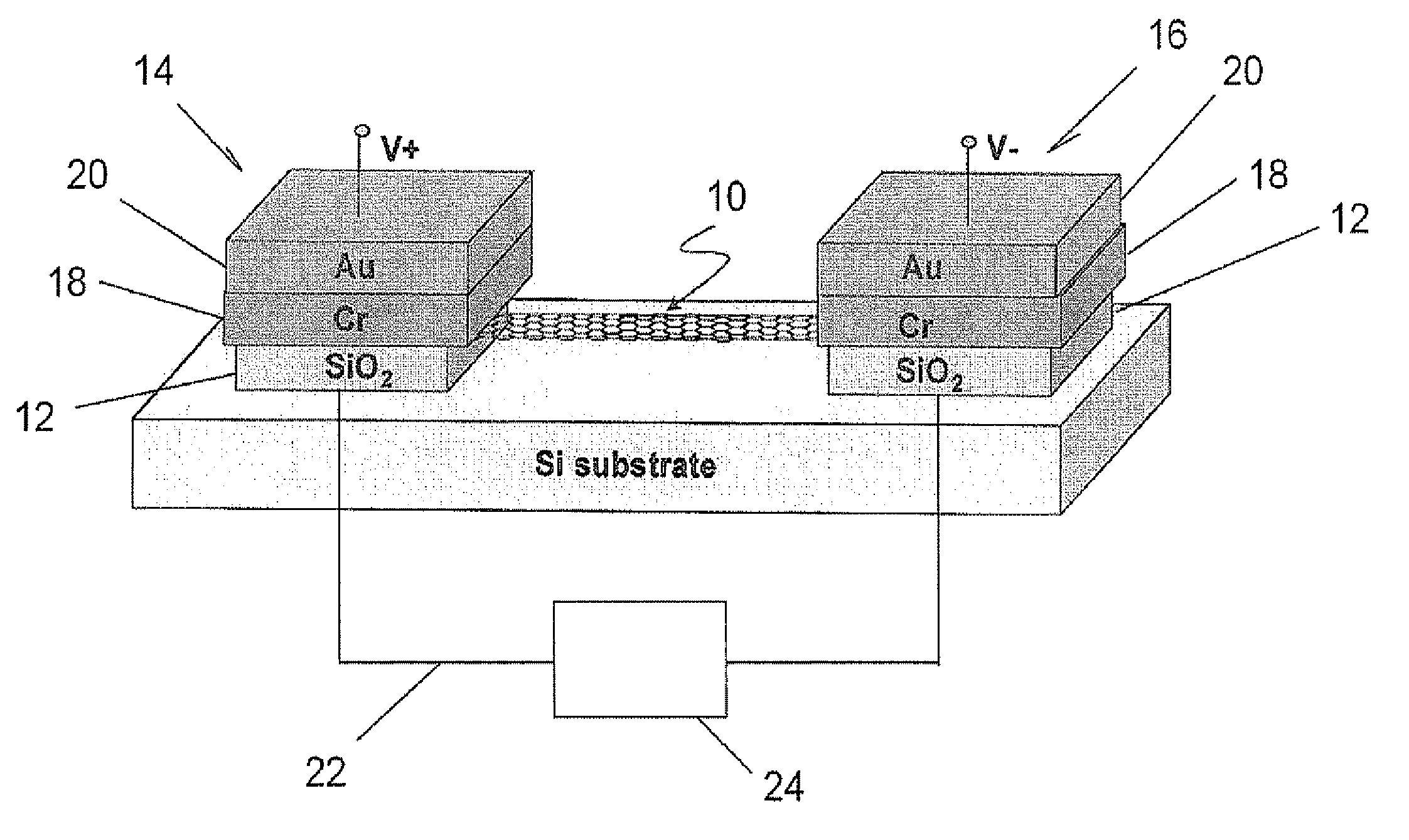

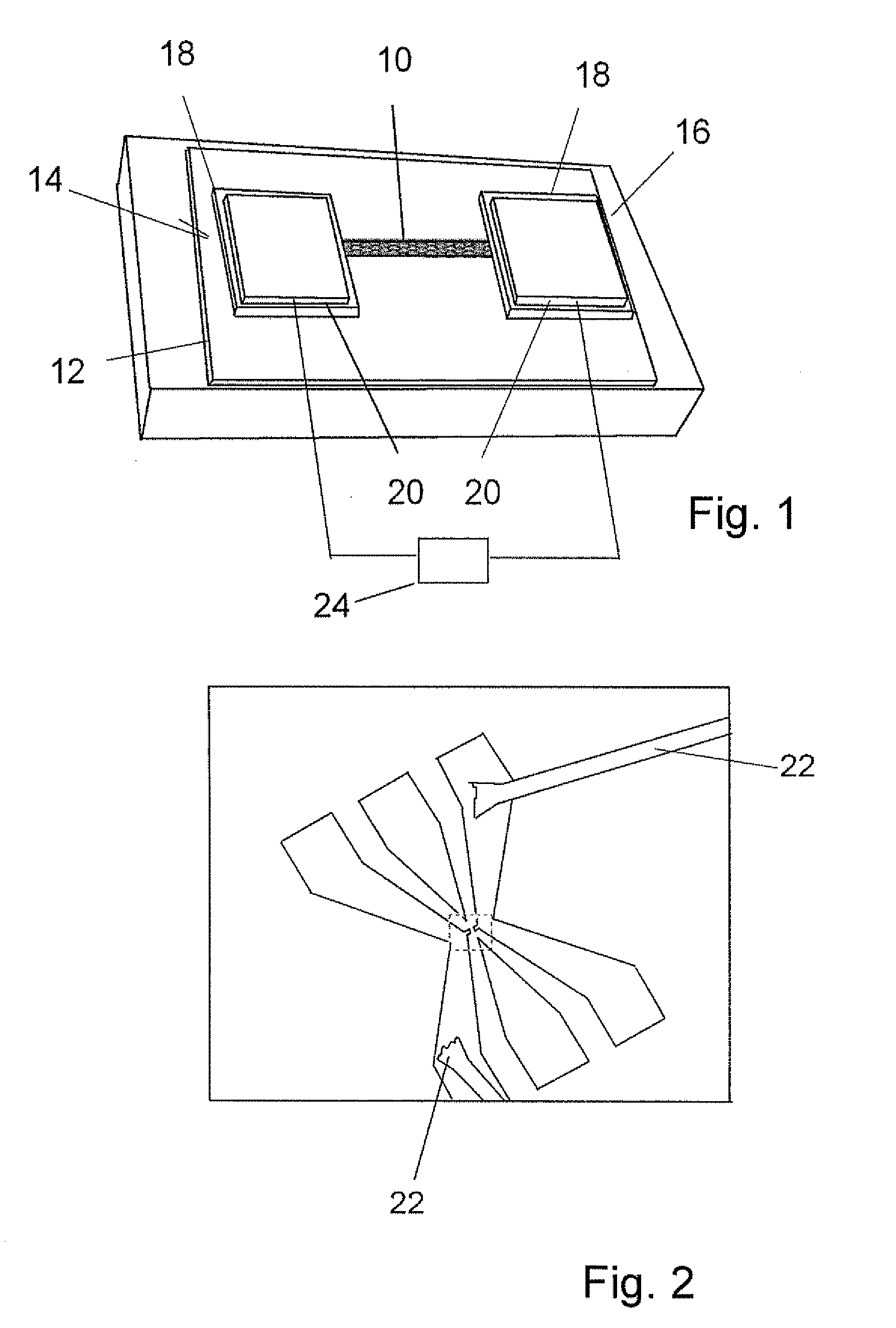

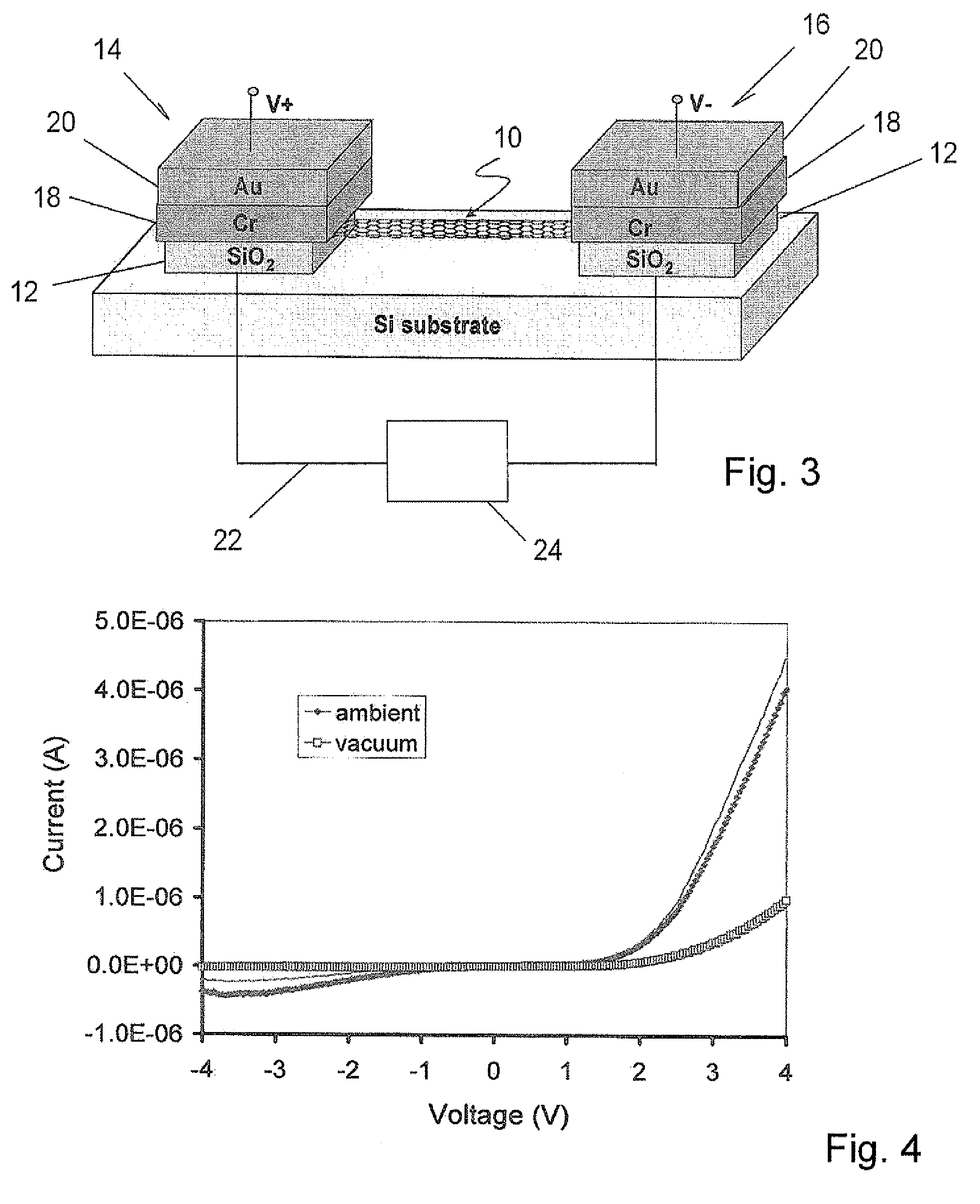

[0022]A miniature carbon nanotube (CNT) based thermal conductivity gauge is schematically illustrated in FIG. 1. A single-walled-nanotube (SWNT) 10 is supported on an SiO2 substrate 12. Two Au / Cr electrodes 14, 16 formed on the substrate 12 receive the ends of the SWNT 10. The SiO2 substrate 12 may be etched away beneath the SWNT 10 to suspend the SWNT 10 from the electrodes 14, 16 in separation from the substrate 12. The typical tube length of the SWNT 10 between electrodes is 5 μm to 10 μm. The miniature CNT-based thermal conductivity gauge has a volume ˜10−4 cm3 and operates at low power (nW-μW) and low temperatures. The CNT gauge exhibits a wide dynamic range of 760 Torr-10−6 Torr.

[0023]In fabrication, the starting substrate is a thermally oxidized Si wafer 12. Patterned chemical vapor deposited growth of the SWNT 10 employs Fe-catalyst. Reference is made to J. Kong, H. Soh, A. Cassell, C. F. Quate, and H. Dai, “Synthesis of individual single walled carbon nanotubes on patterne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com