Monolithic ceramic electronic component and method for manufacturing the same

a technology of monolithic ceramics and electronic components, applied in the direction of fixed capacitor details, stacked capacitors, transportation and packaging, etc., can solve the problems of kirkendall voids in the plated layer and deterioration in product lifetime, and achieve the effect of effectively preventing the occurrence of kirkendall voids, reducing the diffusion of the main component metal of the plated layer in the internal electrode, and improving product lifetime in a load test environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

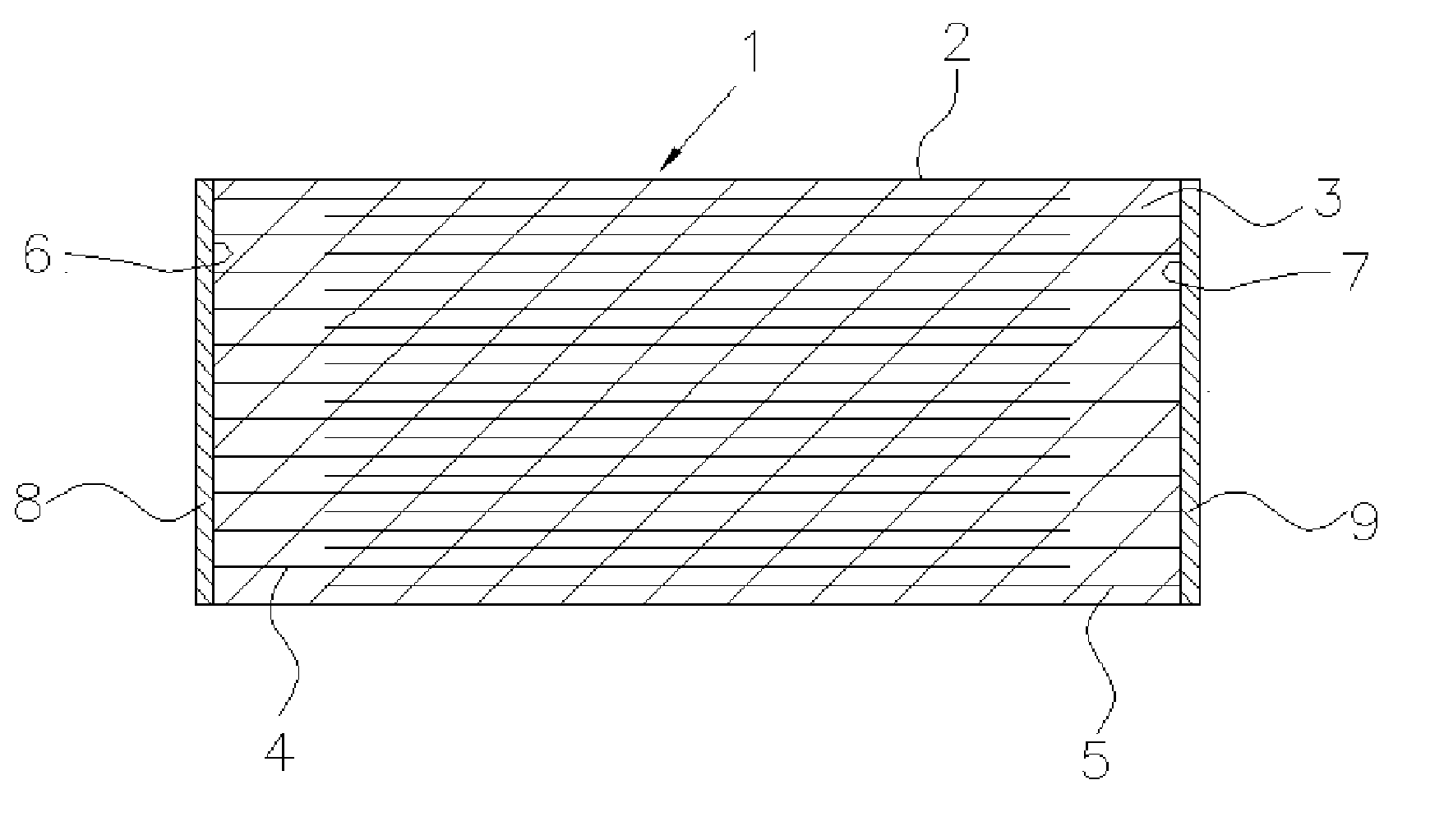

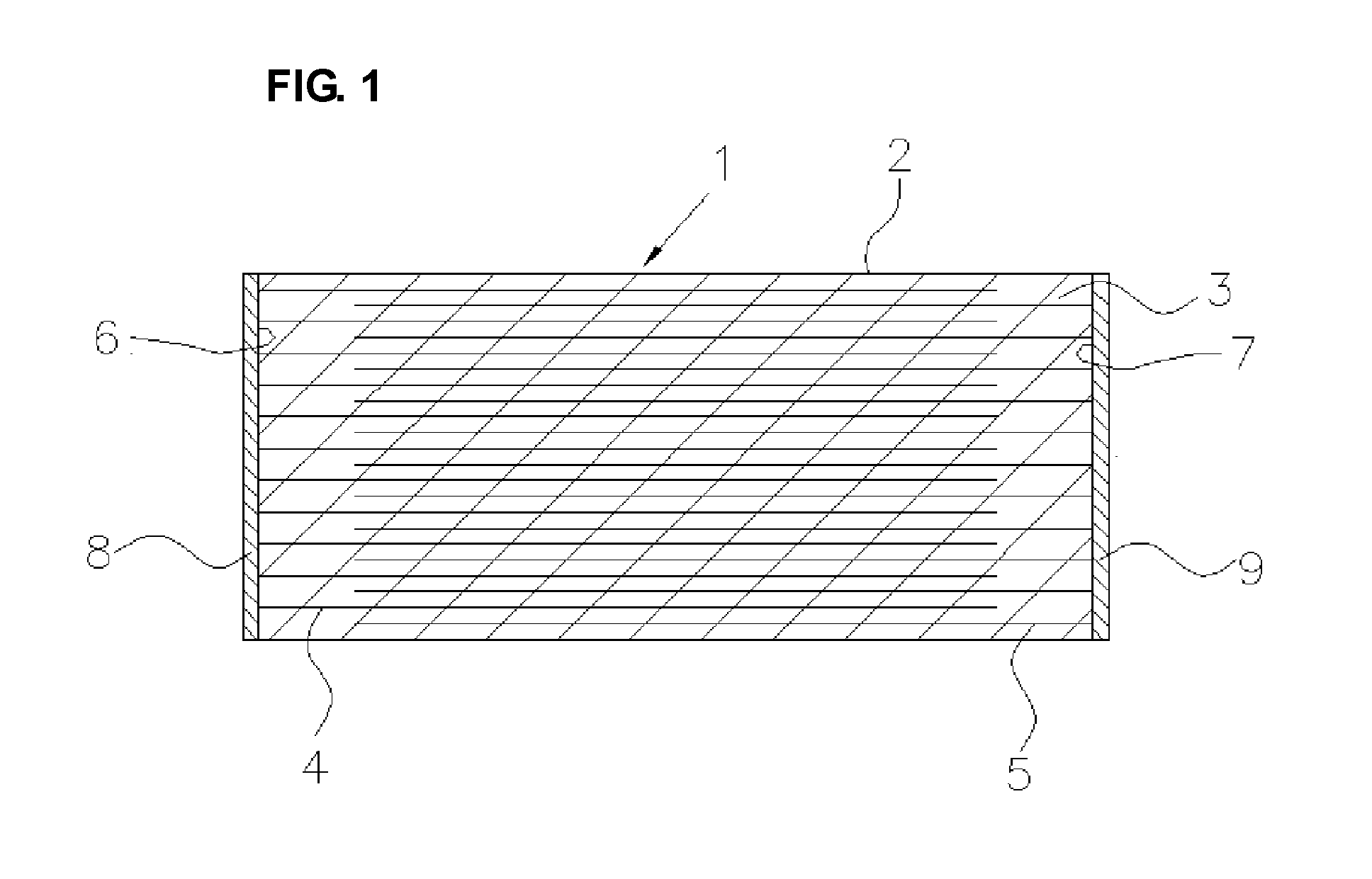

[0029]A monolithic ceramic electronic component 1 according to a first preferred embodiment of the present invention and a method for manufacturing the monolithic ceramic electronic component 1 are described below with reference to FIGS. 1 and 2.

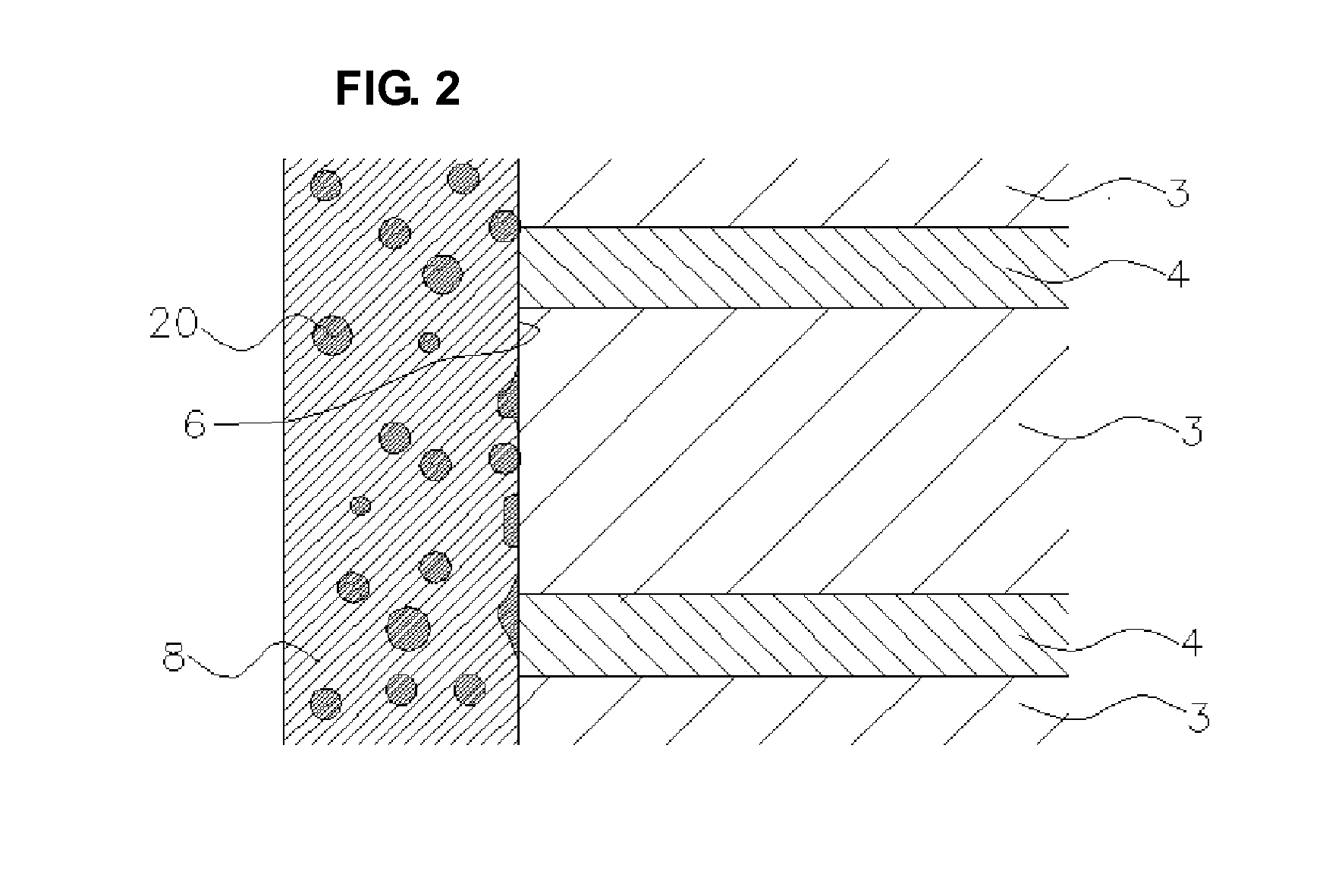

[0030]As illustrated in the cross-sectional view of FIG. 1, the monolithic ceramic electronic component 1 includes a laminate 2, which includes laminated ceramic layers 3 and internal electrodes 4 and 5 alternately disposed between the ceramic layers 3. When the monolithic ceramic electronic component 1 is a monolithic ceramic capacitor, the ceramic layers 3 are composed of dielectric ceramic. An end of each of the internal electrodes 4 is exposed at an end surface 6 of the laminate 2. An end of each of the internal electrodes 5 is exposed at an end surface 7. External electrodes are formed on the end surfaces 6 and 7 to electrically connect the corresponding ends of the internal electrodes 4 and 5.

[0031]The external electrodes include first...

second preferred embodiment

[0045]FIG. 4 is a cross-sectional view of a monolithic ceramic electronic component 51 according to a second preferred embodiment of the present invention. A method for manufacturing the monolithic ceramic electronic component 51 is described below.

[0046]First, a laminate 2 is prepared as in the first preferred embodiment. First plated layers 8 and 9 are formed as in the first preferred embodiment on end surfaces 6 and 7 of the laminate 2 at which internal electrodes 4 and 5 are exposed. The first plated layers 8 and 9 are formed of a metal different from that of the internal electrodes 4 and 5.

[0047]The second preferred embodiment is different from the first preferred embodiment in that second plated layers 10 and 11 primarily composed of the same or substantially the same metal that defines the internal electrodes 4 and 5 are formed on the first plated layers 8 and 9 and that the laminate 2 is subsequently heat-treated at a temperature of at least about 800° C. The heat treatment ...

example 1

[0063]A laminate for use in a monolithic ceramic capacitor was prepared as a laminate of a monolithic ceramic electronic component. The laminate included ceramic layers made of barium titanate-based dielectric ceramic and internal electrodes primarily made of Ni. The laminate had a length of about 1.9 mm, a width of about 1.05 mm, and a height of about 1.05 mm. Each of the ceramic layers had a thickness of about 2.0 μm. The distance between adjacent internal electrodes on a surface at which the internal electrodes were exposed was about 4.0 μm.

[0064]Five hundred laminates were charged in a horizontal rotating barrel having a volume of about 290 mL. A hundred milliliters of electroconductive media having a diameter of about 1.3 mm were charged in the barrel. The rotating barrel was immersed in a Cu / Ni alloy plating bath controlled at a pH of about 8.7 and a temperature of about 25° C. An electric current was applied at a density of about 0.50 A / dm2 for a predetermined period of time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com