Method and system for fuel vapor control

a technology of fuel vapor and purging method, applied in the direction of combustion air/fuel air treatment, machine/engine, process and machine control, etc., can solve the problems of insufficient purging of fuel vapor from the vehicle's emission control system, refueling and emission control system leak detection operations dependent on pressure and vacuum, and operation may also be affected, so as to reduce the overall carbon emissions of the vehicle, shorten the engine operation time, and reduce the effect of engine operation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

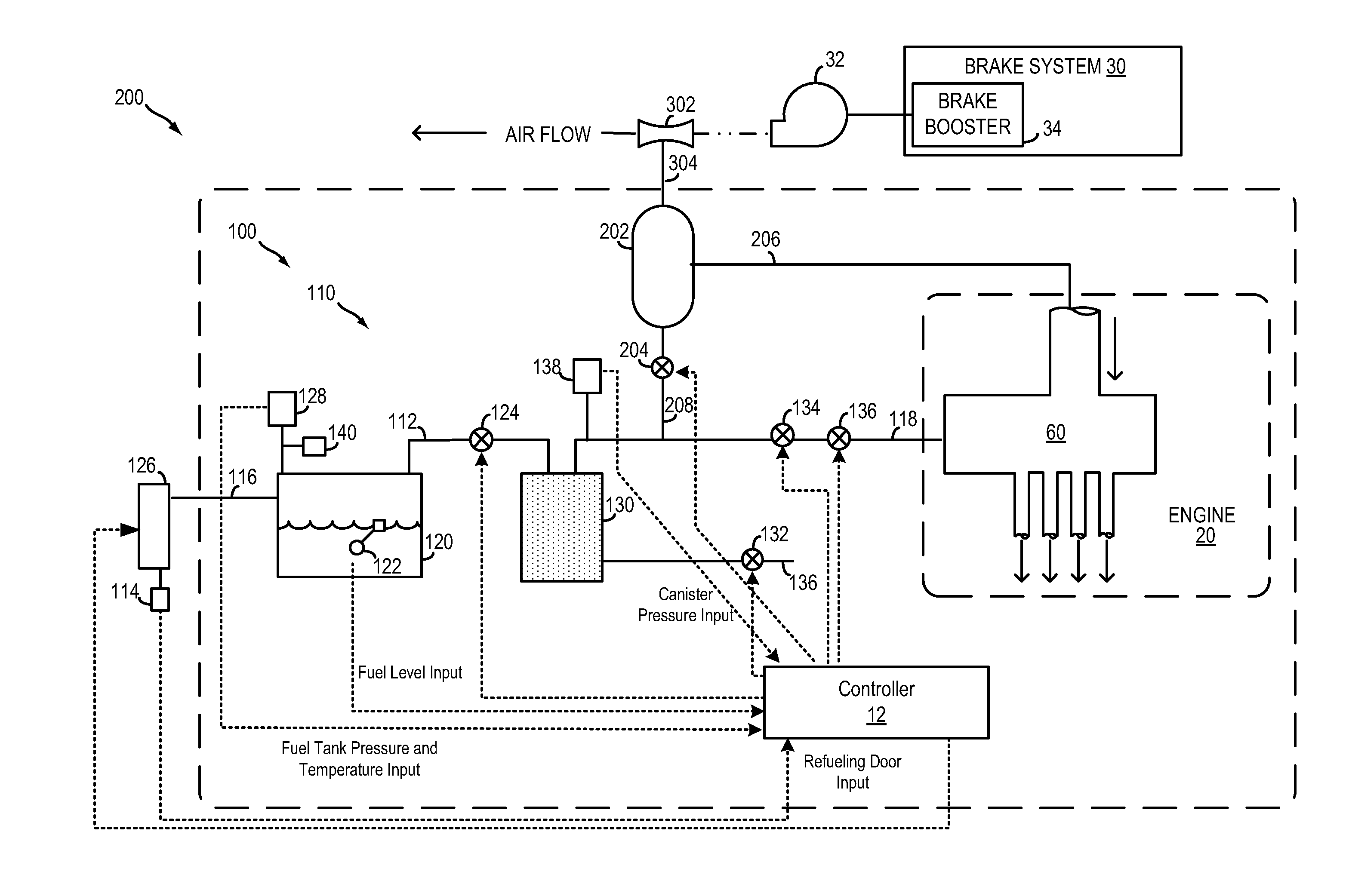

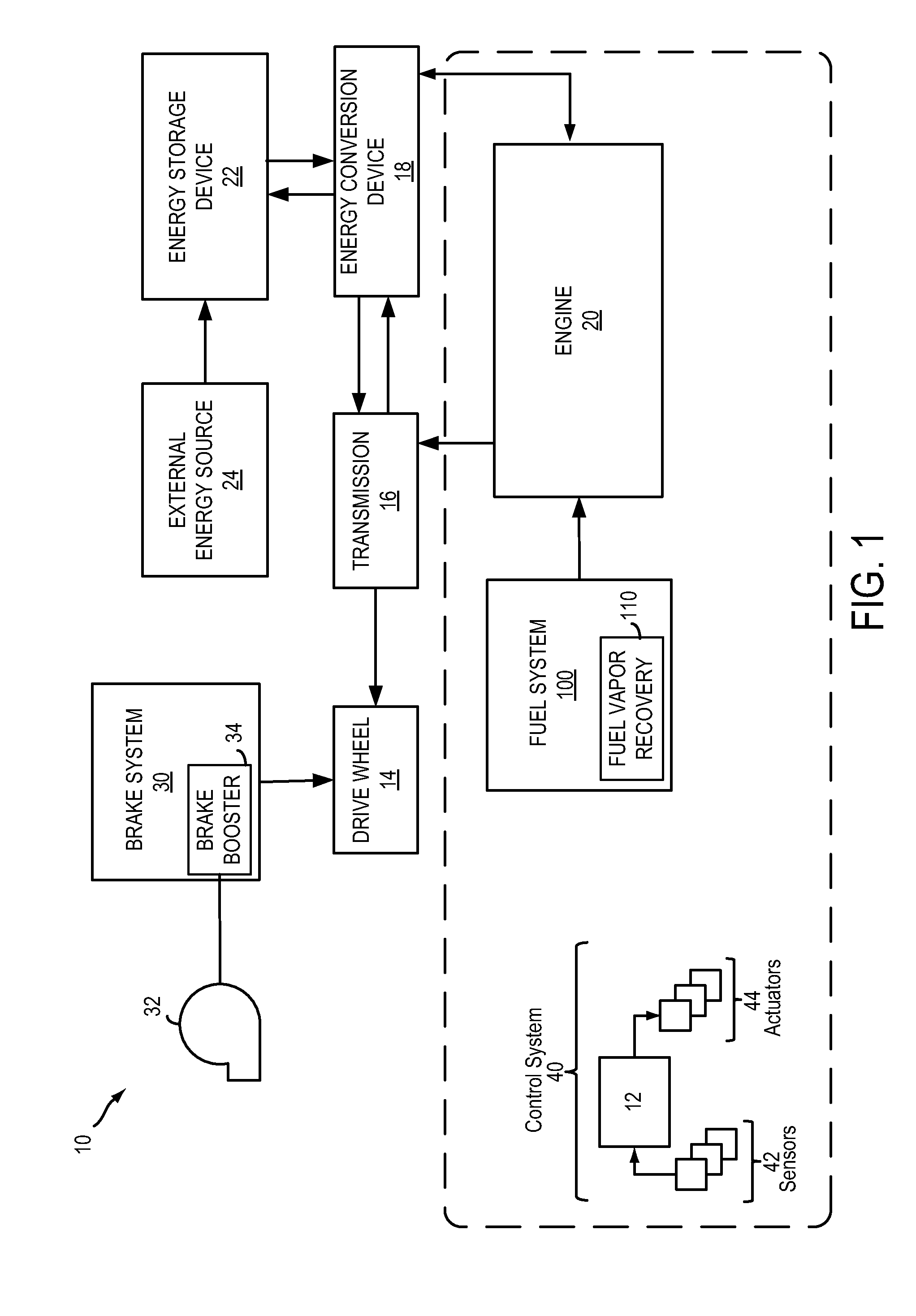

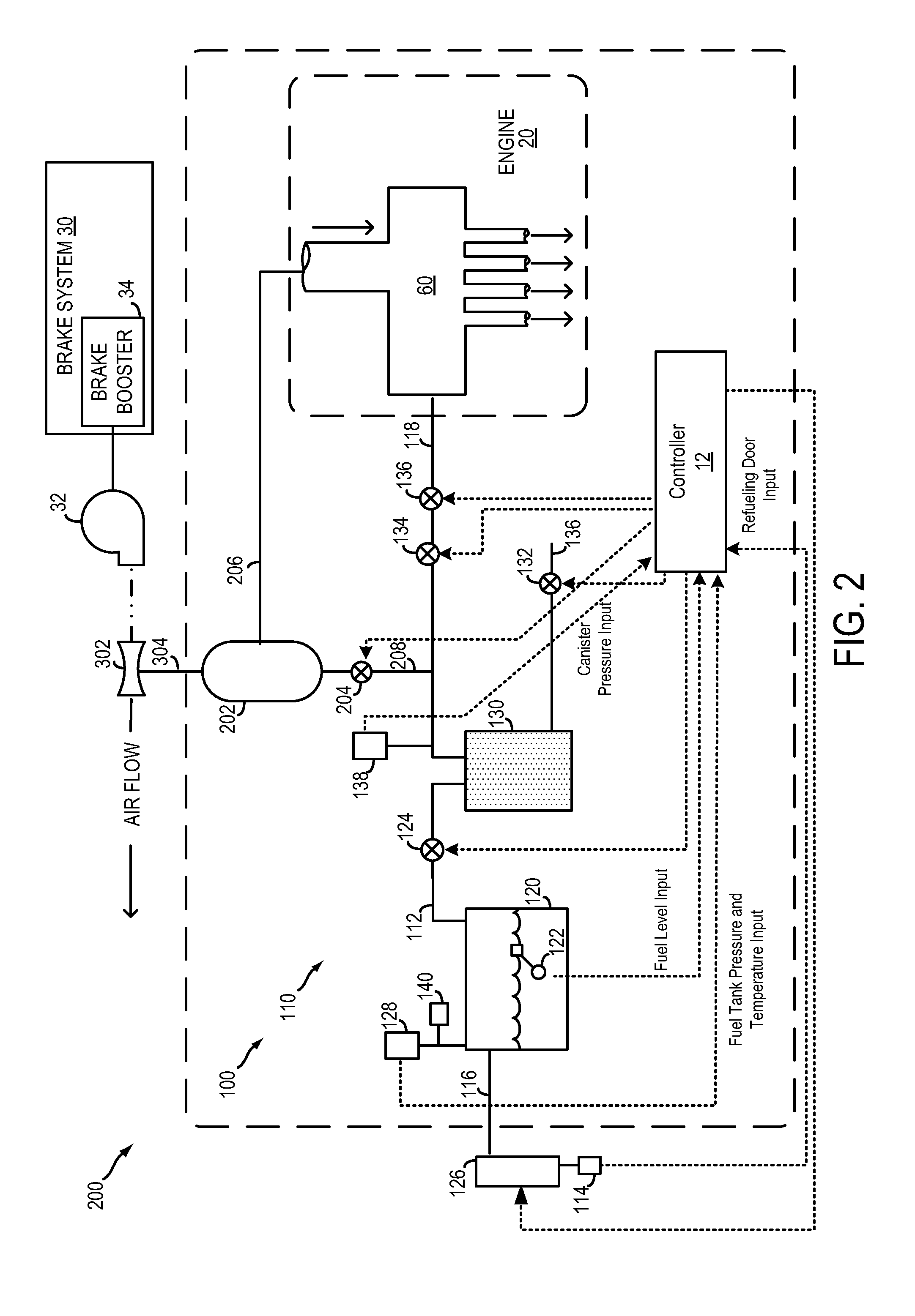

[0020]The following description relates to a fuel vapor recovery system for a hybrid vehicle, such as the vehicle system of FIG. 1, and a method of monitoring flow of fuel vapors and / or air though the fuel vapor recovery system. As shown in FIG. 2, the fuel vapor recovery system may include a fuel tank isolated from a canister by a fuel tank isolation valve (FTIV), the canister further coupled to an engine intake by a canister purge valve (CPV). In this way, refueling vapors may be stored in the canister while diurnal vapors are retained in the fuel tank, dividing the fuel vapor circuit into a canister side and a fuel tank side. A vacuum accumulator may be included in the fuel vapor recovery system to provide a vacuum source to the canister. The vacuum accumulator may be configured to generate and store vacuum during engine-on conditions and engine-off conditions, such as from the engine and / or from a brake booster pump. A controller may receive signals from various sensors includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com