Direct drive distributed generator integrated with stayed rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

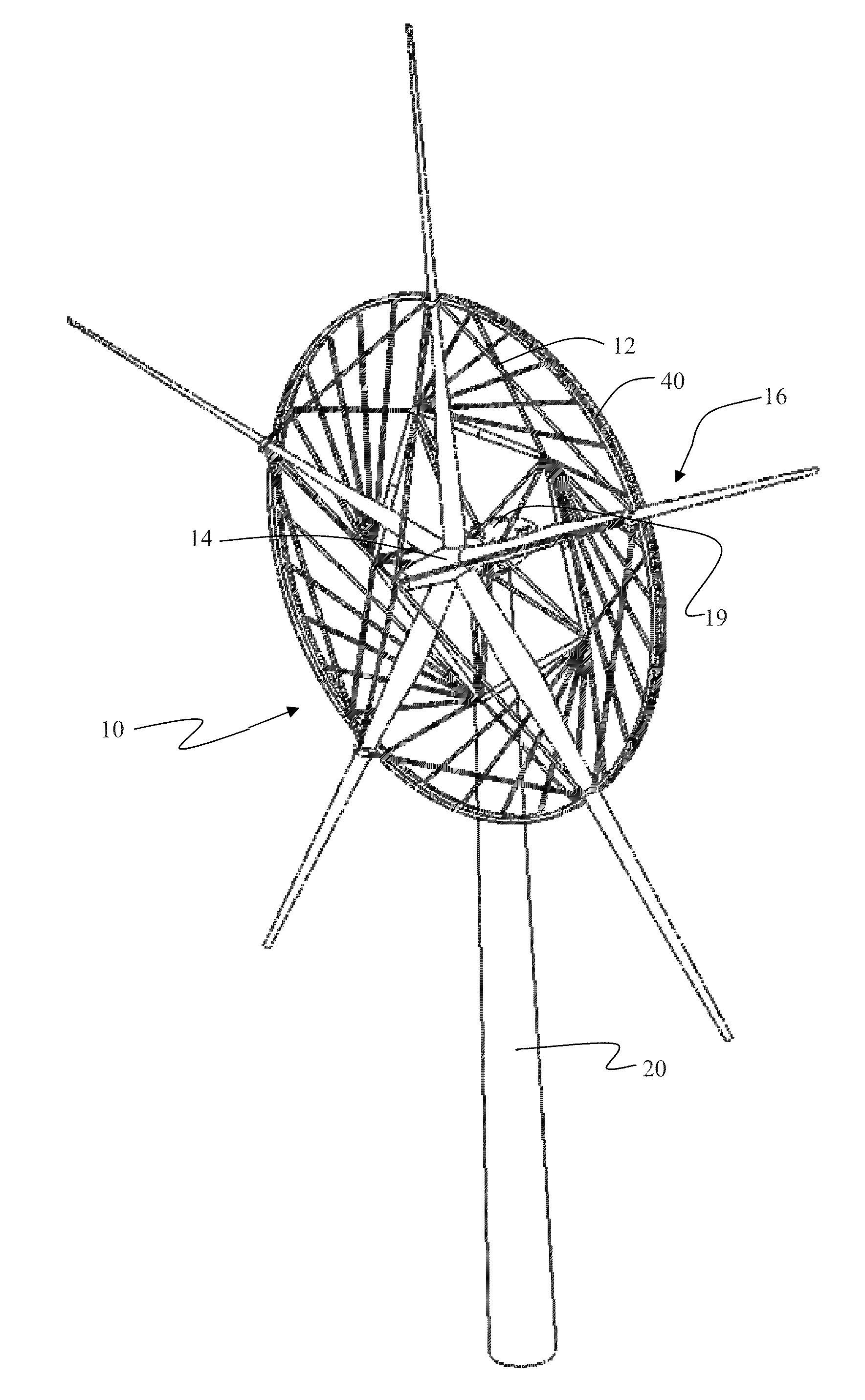

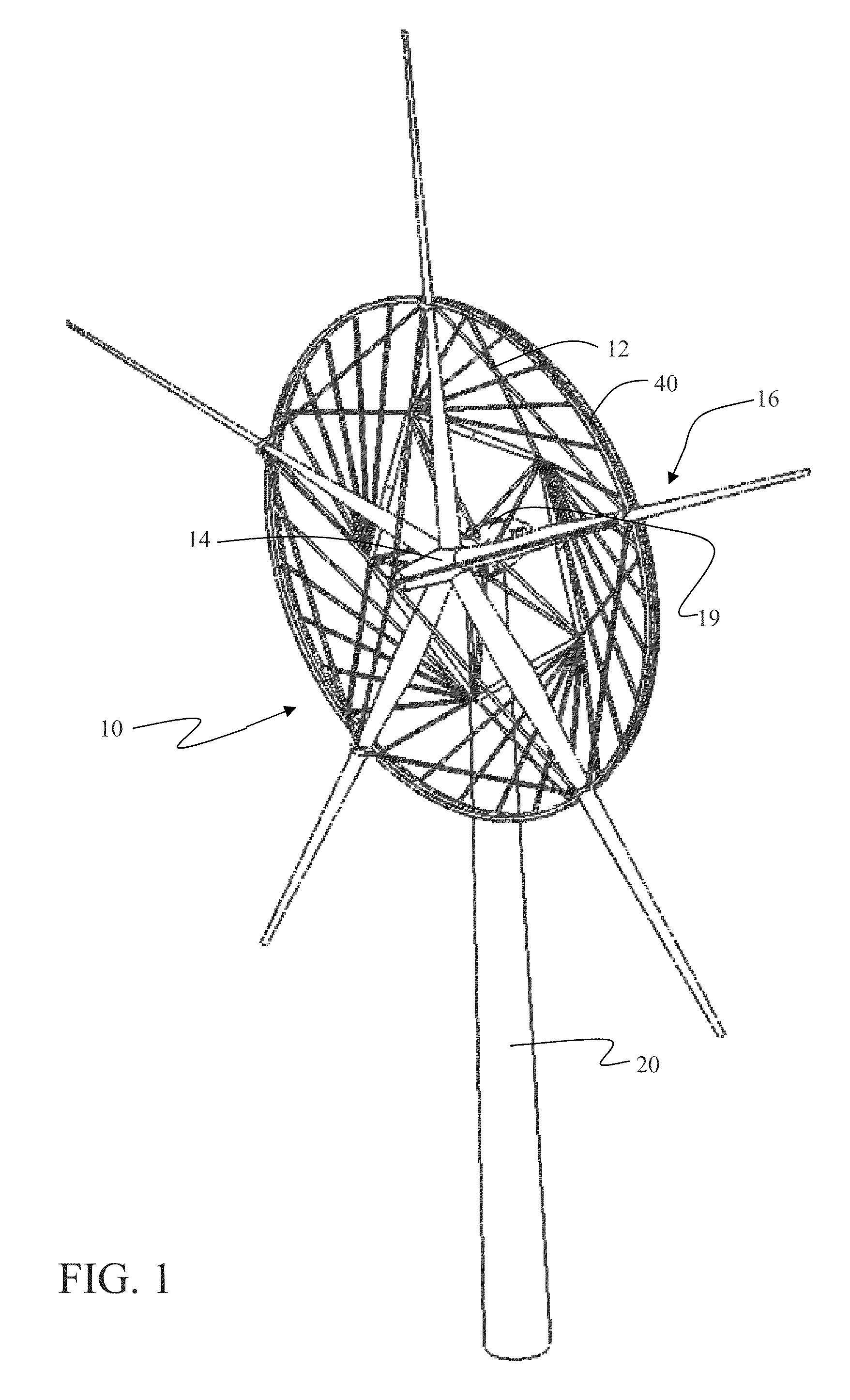

[0022]Embodiments of the invention incorporate a very large scale (˜10 MW) wind turbine multi-blade rotor 10 as shown in FIG. 1. Each blade 16 is constrained through a system of stay cables 12 from a rotor hub 14 attaching to a point ⅓ to ½ of the length of each blade from the hub. A collar 18 on each blade provides the attachment points for the stay cable system as will be described in greater detail subsequently. Each collar is also connected by stay cables to the adjoining blades' collars. A bearing system in the collar allows for the blade to have full pitch movement. The cable-stayed blade enables much greater swept area and lower cost than is currently possible with blades joined solely at the blade root to the hub. The rotor is supported by a nacelle 19 mounted from the ground by a tower 20.

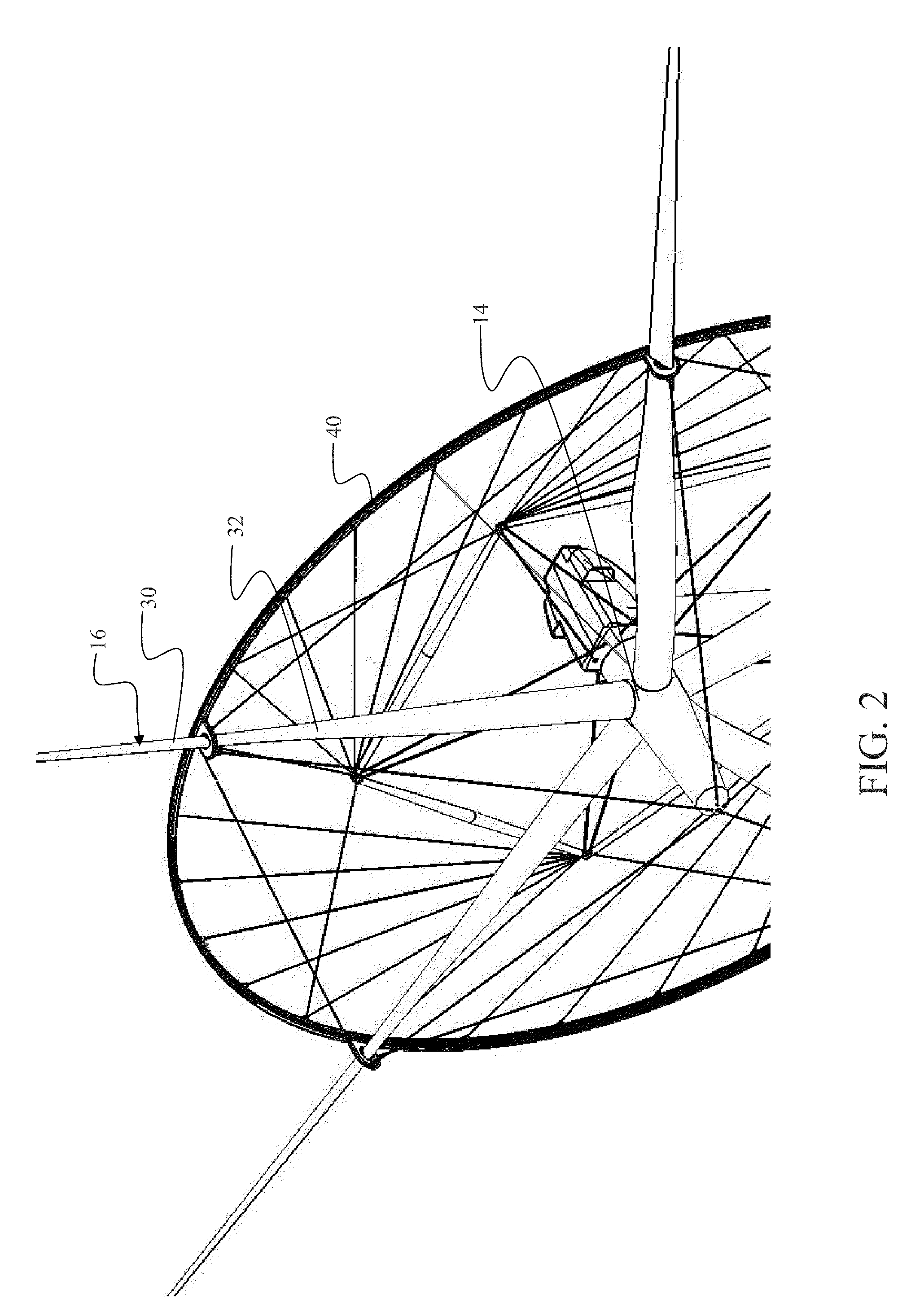

[0023]As seen in FIGS. 2 and 3, each collar 18 incorporates a first attach point 22 for a forestay cable 24 and opposing side attach points 26 for interblade lead and lag stay cables 28, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com