Method for forming light emitting device

a technology of light-emitting devices and forming methods, which is applied in the direction of semiconductor devices, electrical devices, nanotechnology, etc., can solve the problems of long current path, high device resistance, and difficult to remove the generated hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]It is understood that specific embodiments are provided as examples to teach the broader inventive concept, and one of ordinary skill in the art can easily apply the teaching of the present disclosure to other methods or apparatus. The following discussion is only used to illustrate the invention, not limit the invention.

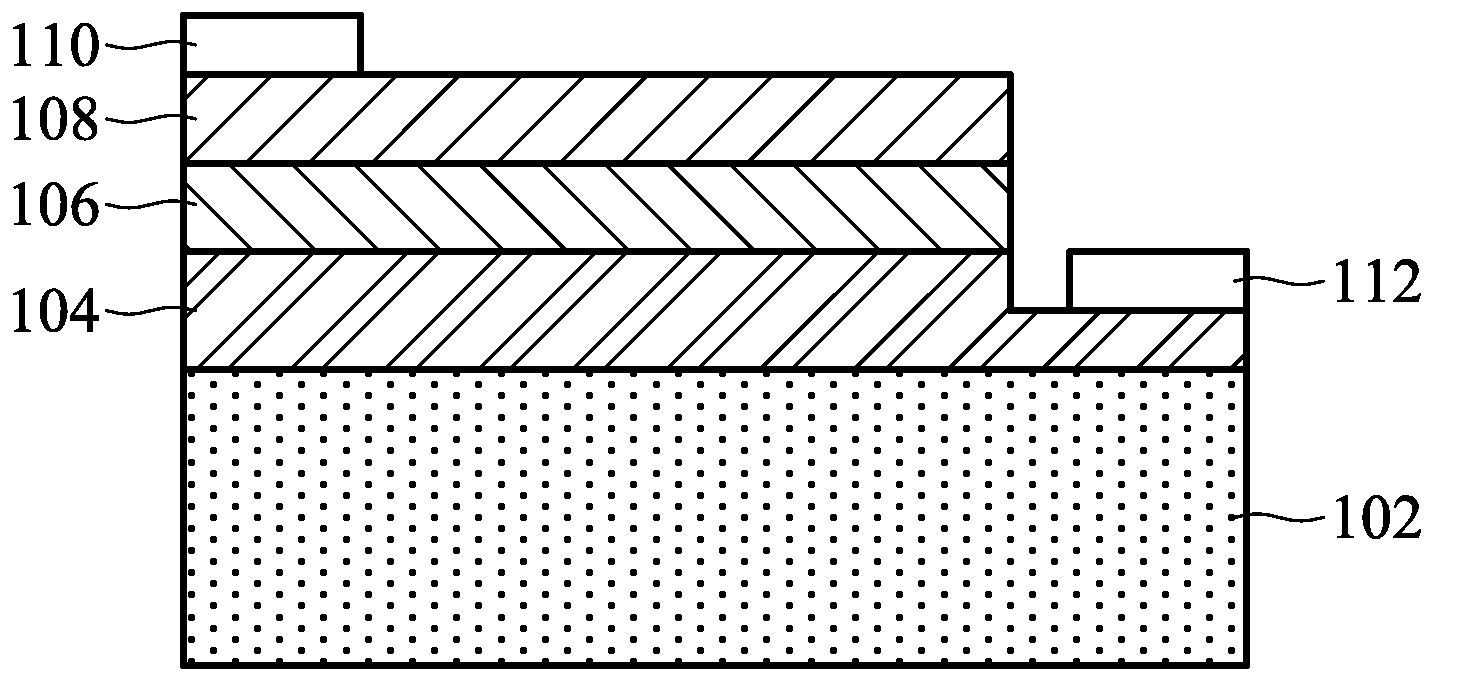

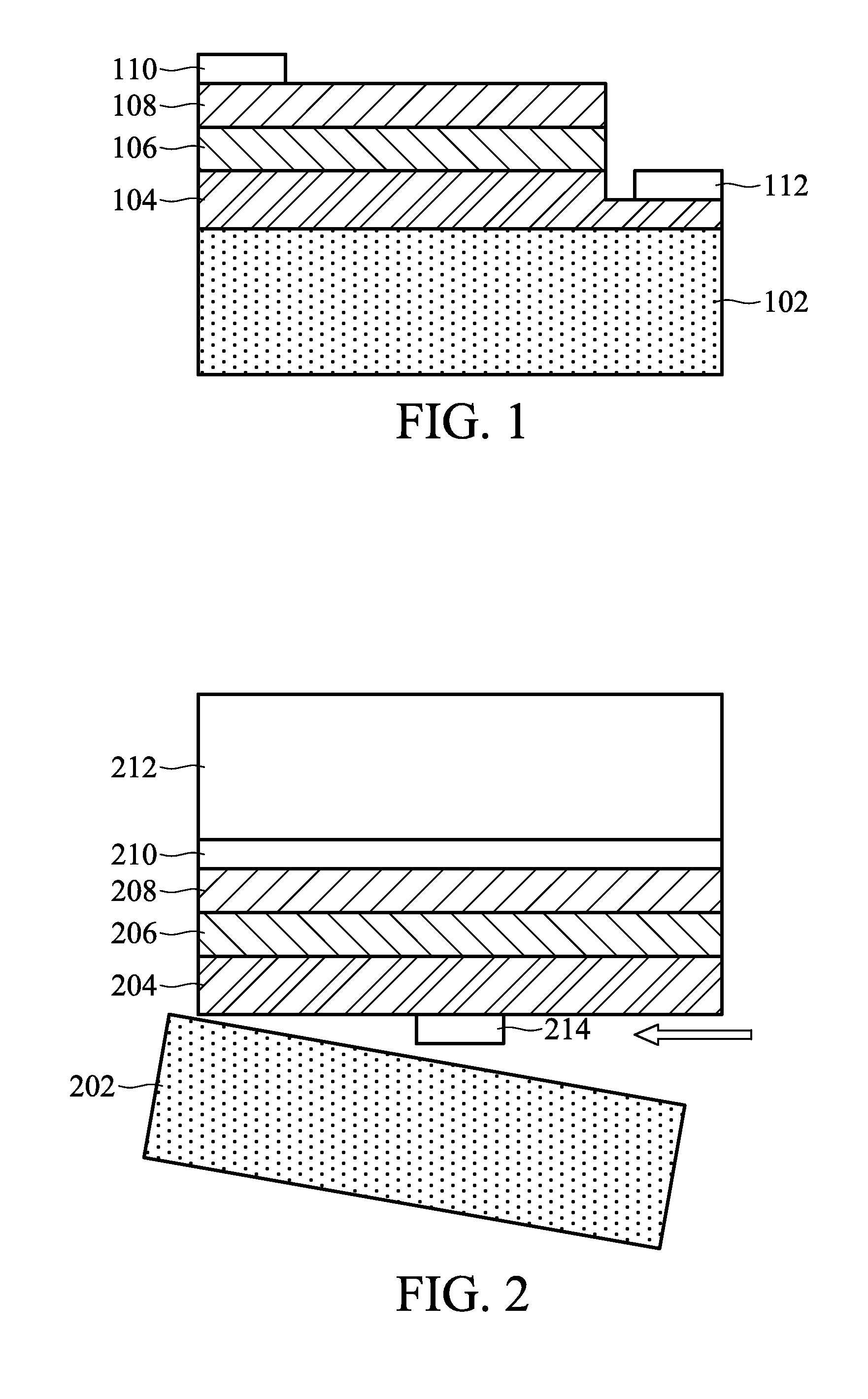

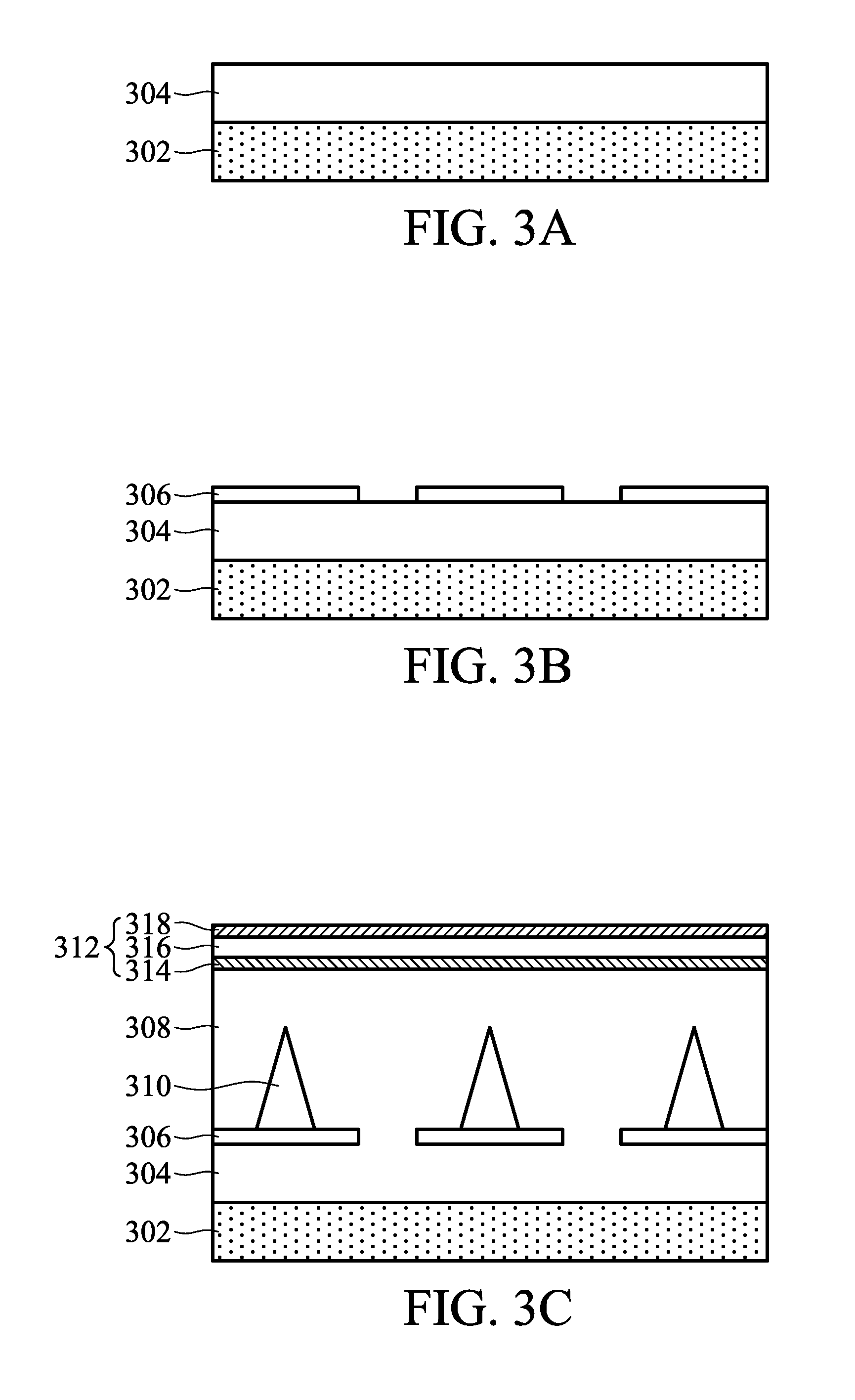

[0021]A method for forming a vertical light emitting diode of an embodiment of the invention is illustrated in accordance with FIGS. 3A˜3G. First, referring to FIG. 3A, a first substrate 302 such as sapphire substrate is provided. A semiconductor layer 304 is formed on the first substrate 302. In an embodiment of the invention, an undoped GaN layer with thickness of about 400 nm is deposited on the first substrate 302 by metal-organic chemical vapor deposition (MOCVD). Referring to FIG. 3B, a plurality of patterned masks 306 are formed on the undoped GaN layer 304. In an embodiment of the invention, the patterned mask layer 306 is a stripe-shaped silicon oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com