Method of controlling road dust in strip mines

a strip mine and dust control technology, applied in the direction of roads, coatings, construction, etc., can solve the problems of inability to properly paved roads at excavation sites, inability to create large amounts of dust, and inability to properly paved roads, etc., to achieve the effect of reducing lung and machinery damage, prolonging and repeating the service life, and increasing the efficiency of current dust control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

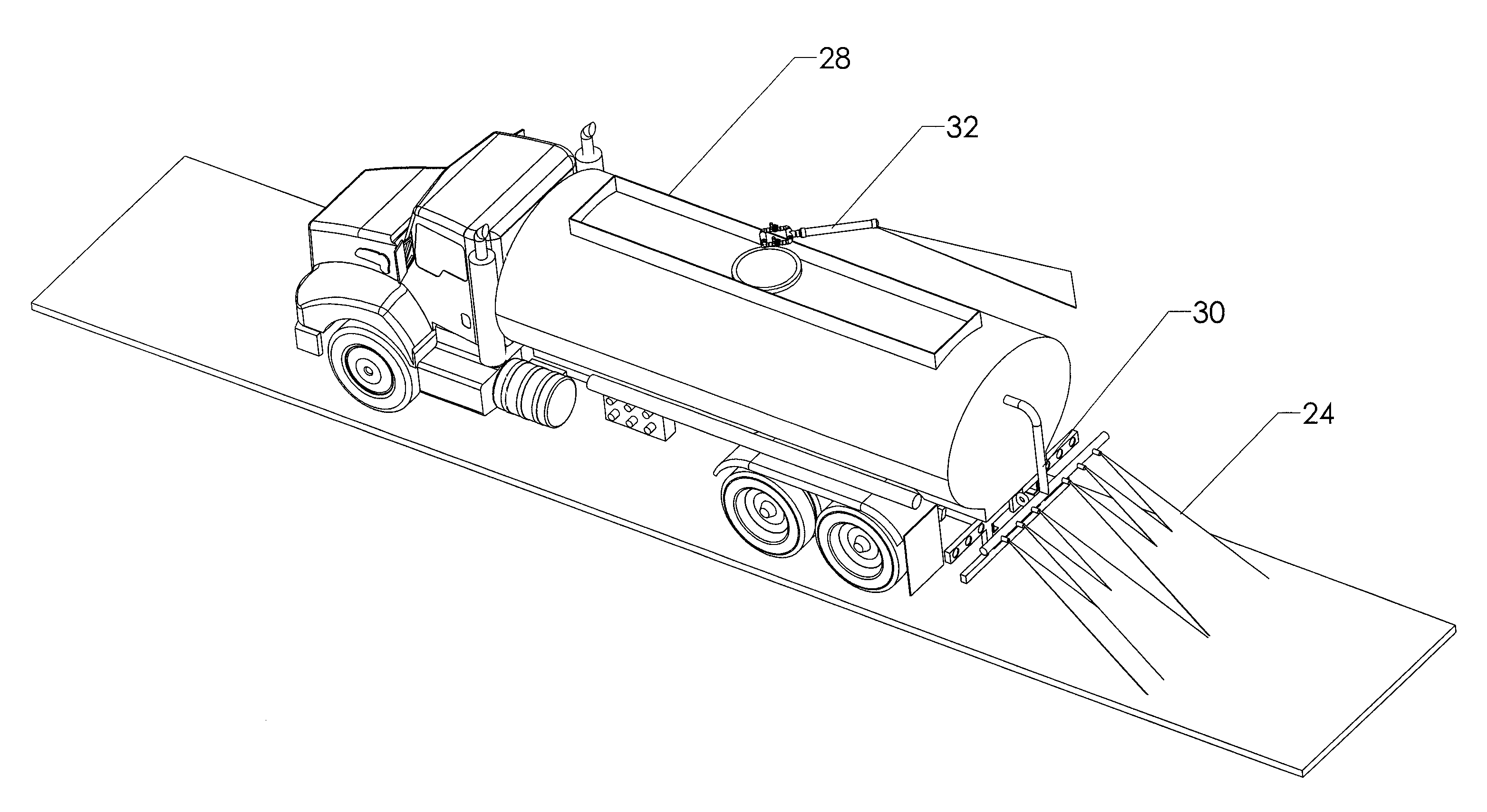

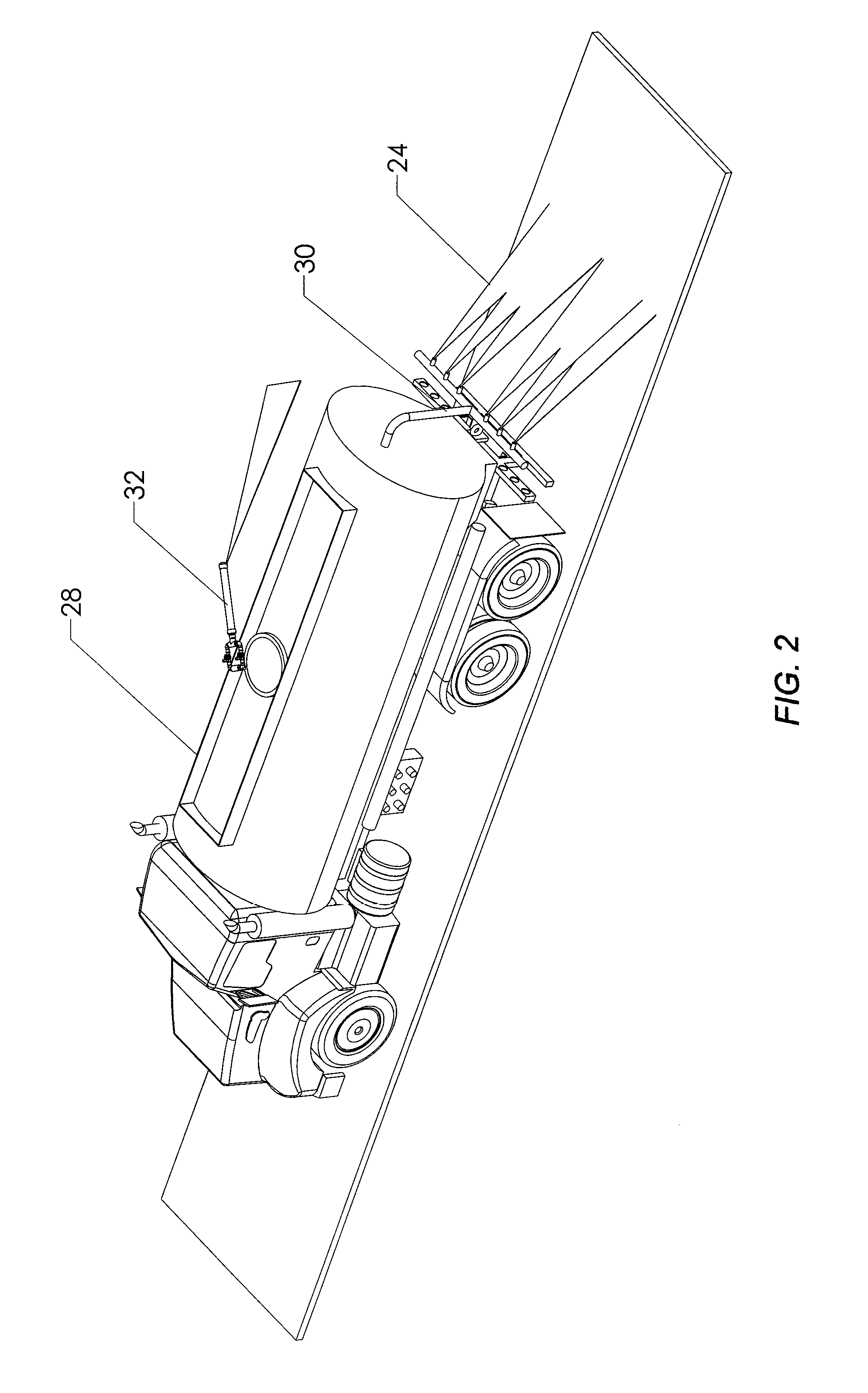

[0032]Usually, for dust controlling solutions, the most preferred application method is spraying a mixture of the polymer and water over the road in a quantity sufficient to cover the dust. Several solution concentrations were tested and it was found that the minimum polymer concentration to achieve an excellent dust suppression level is of about 15 gallons of polymer to 2000 gallons of water. Thus, in a tanker 20 holding multiples of 2,000 gallons of water, add 15 gallons of super absorbent polymer through the manhole for each 2,000 gallons. The polymer is stirred until wetted and the movement of the tanker 20 provides the necessary agitation to uniformly admix the polymer and water. The tanker can then be used in its ordinary and conventional manner for distribution of water over the gravel roads. The polymer maintains the water for a much longer period of time by preventing the water from leaching into the ground, as well as controlling the amount of evaporation.

[0033]The inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com