Heat exchanger device with heat-radiative coating

a heat exchanger and coating technology, applied in indirect heat exchangers, lighting and heating apparatus, furnaces, etc., can solve the problems of not having, previously proposed, to improve the heat storage capability and work efficiency of heat retainers, and achieve high efficiency and energy saving. , the effect of facilitating heat exchang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

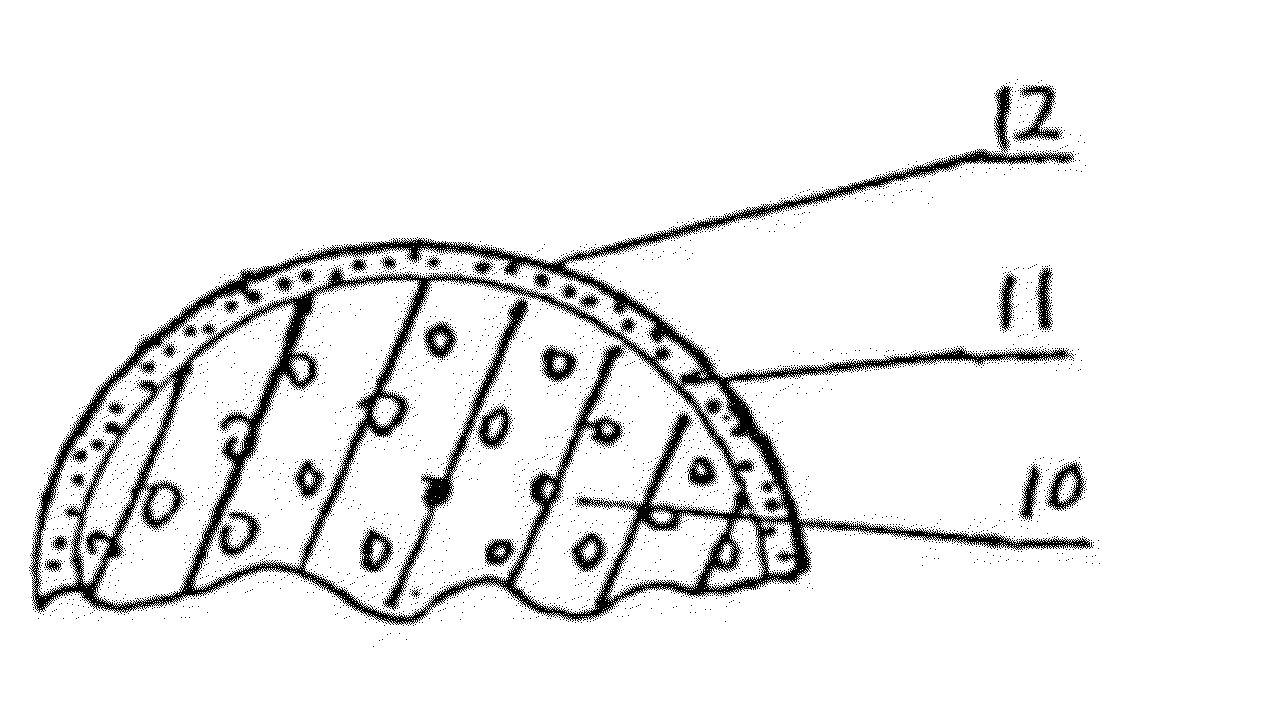

[0110]As shown in FIG. 1, a heat retainer used for a hot blast stove of a blast furnace is a checker brick. The checker brick (heat retainer) has a plurality of circular inner holes 1, and all surfaces (comprising those of the inner holes) of the check brick (heat retainer) are coated with a coating layer of a high radiative material 2 whose thickness is 0.02 mm. A substrate of the heat retainer is a refractory material, and the high radiative material coating layer 2 is a high radiative material whose emissivity in the far-infrared region is greater than that of a substrate material of the heat retainer.

[0111]The high radiative material coating layer 2 comprises by weight: 110 parts of Cr2O3, 80 parts of clays, 90 parts of montmorillonites, 300 parts of brown corundum, 100 parts of silicon carbides, 400 parts of PA80 adhesive and 100 parts of water. These components are hyperfinely processed, i.e., the mixture is grinded to particles with micro / nano-meter sizes by using superfine p...

example 2

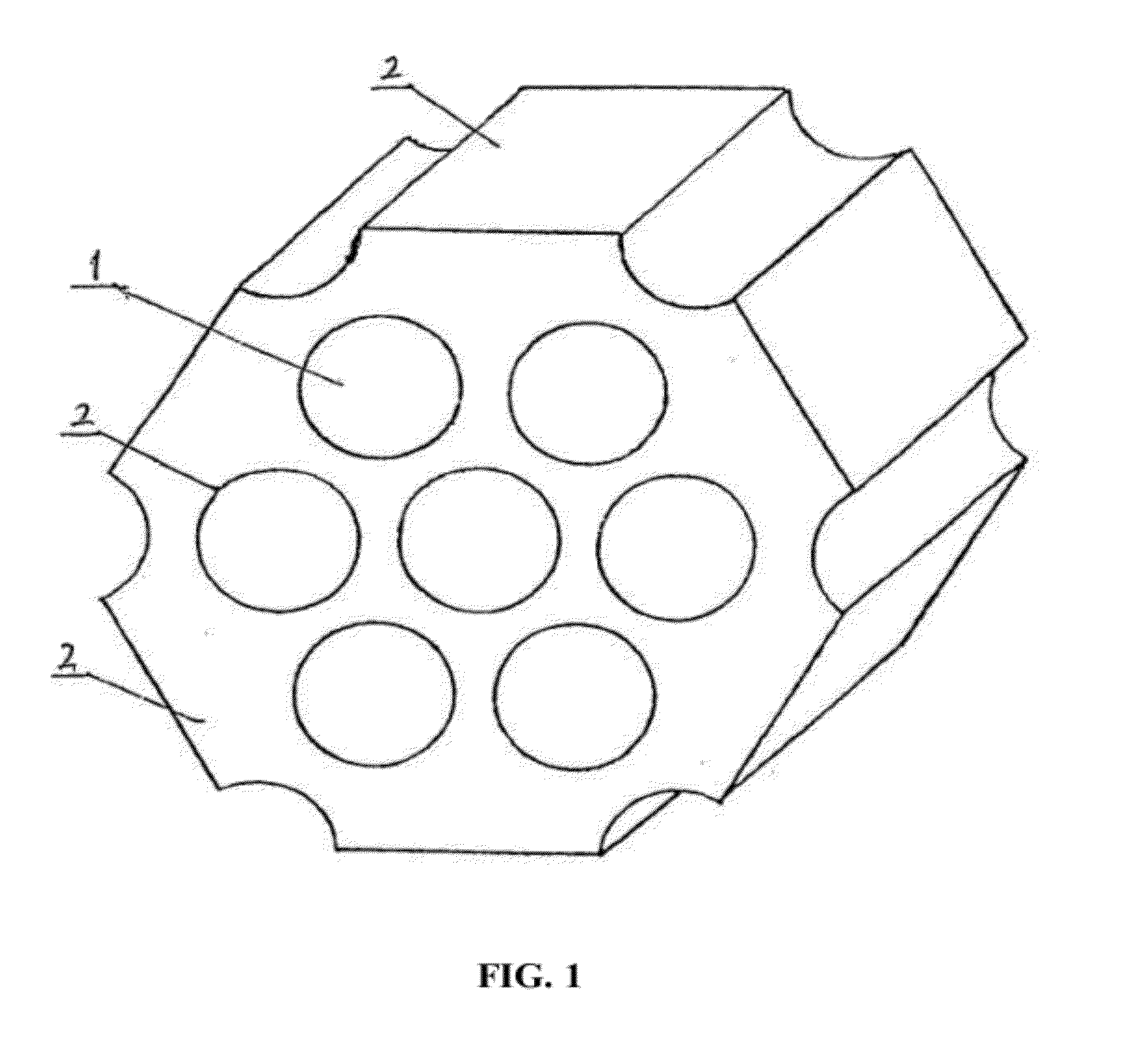

[0112]As described in example 1, except that differences are as follows: the cross section of the honeycomb-shaped heat retainer is rectangular; and the high radiative material coating layer is disposed within a plurality of circular inner holes 3 (as shown in FIG. 2).

example 3

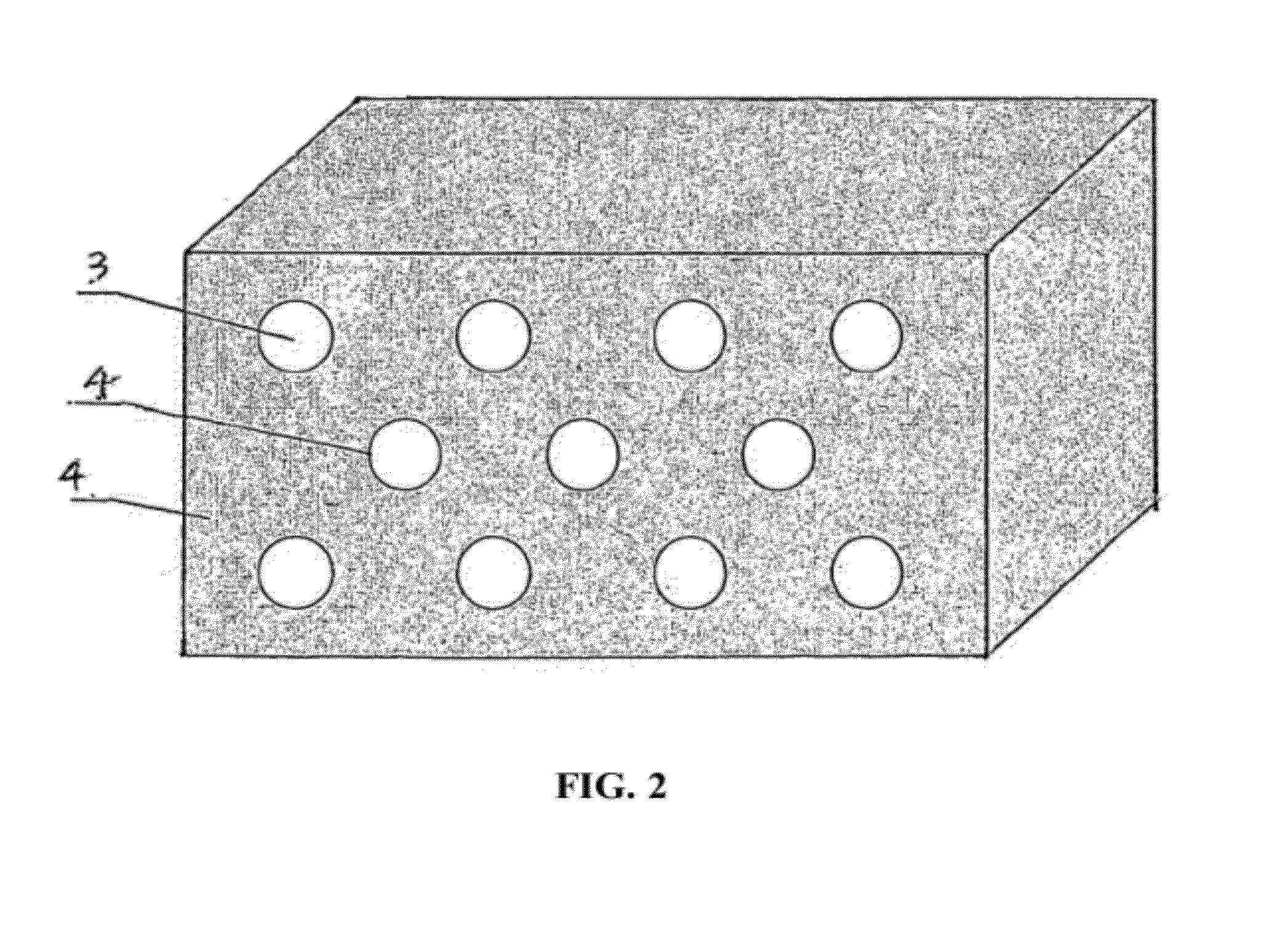

[0113]As shown in FIG. 3, the heat retainer for a heat exchange is fin-shaped. A plurality of rectangular inner holes 5 are disposed in the heat retainer, and all surfaces (comprising surfaces of the inner holes) of the heat retainer for the heat exchanger are paste-coated with a high radiative material coating layer 6 whose thickness is 0.03 mm. A substrate of the heat retainer is a ceramic material, and the high radiative material coating layer 4 is a high radiative material whose emissivity in the far-infrared region is greater than that of a substrate material of the heat retainer.

[0114]The high radiative material comprises by weight: 15 parts of zirconium oxide, 8 parts of Cr2O3, 10 parts of TiO2, 2 parts of montmorillonites, 15 parts of Al2O3, 10 parts of carborundums, 30 parts of PA80 adhesives, and 10 parts of water. Compared with existent heat exchangers, the heat efficiency of the heat exchanger according to this example is improved by over 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com