Lithium secondary battery

a secondary battery and lithium battery technology, applied in the field of lithium secondary batteries, can solve the problems of insufficient research on patent literature 1, internal resistance may rise, path formation may not be found, etc., and achieve the effect of superior battery performance and enhanced ion diffusivity and salt concentration homogeneity in a pole group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

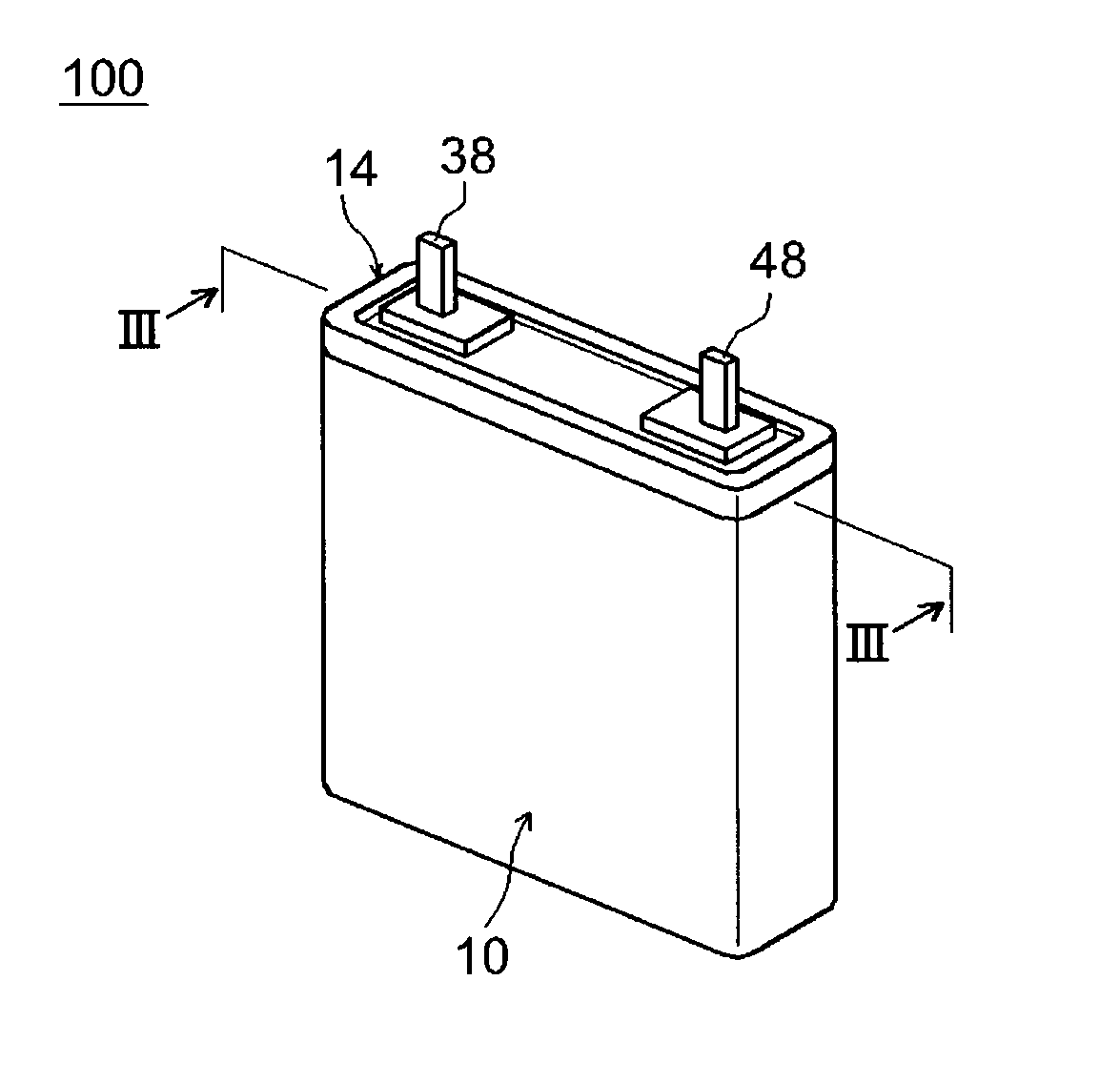

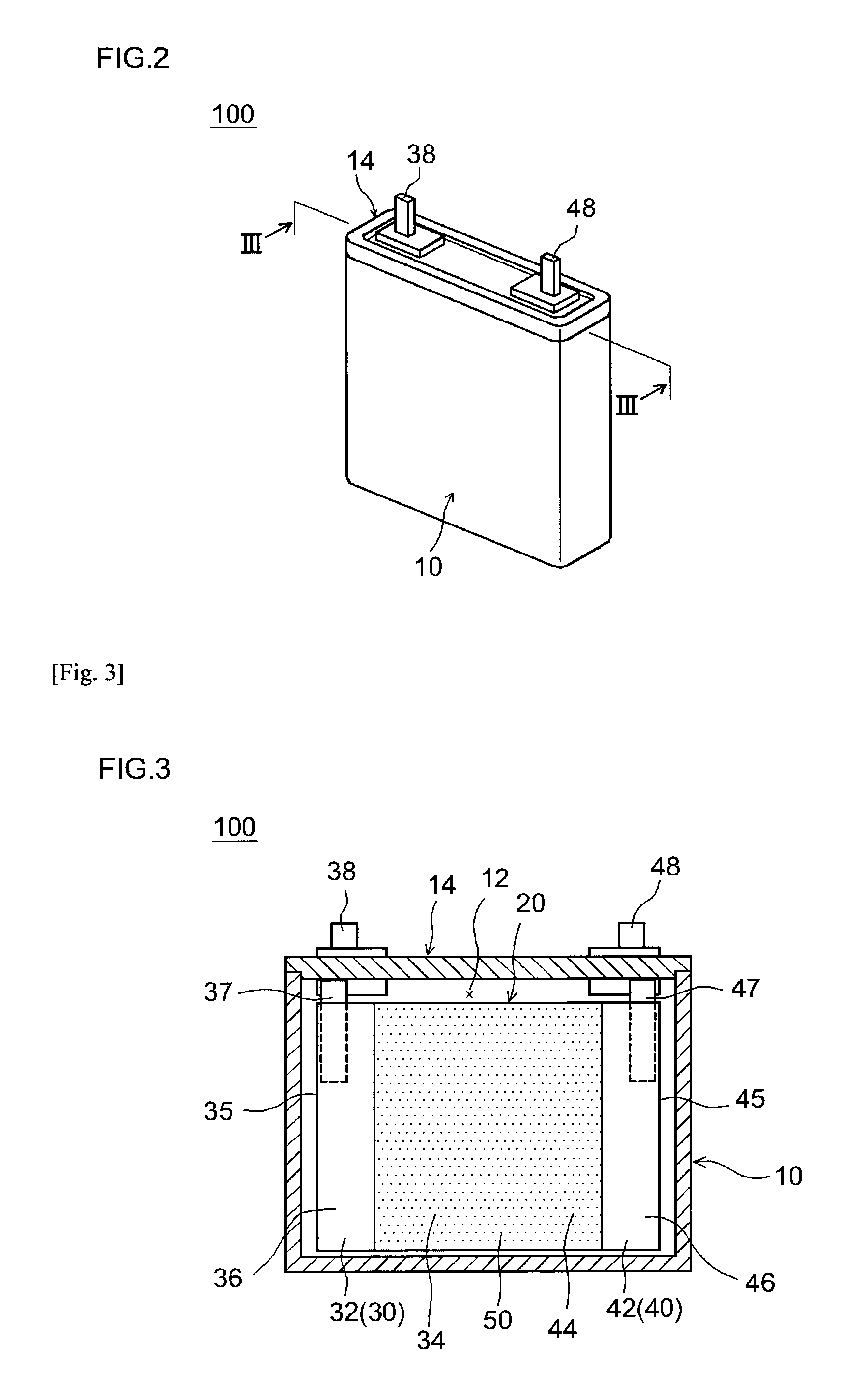

Image

Examples

Embodiment Construction

[0041]Preferred embodiments of the present invention are explained next. Any features other than the features specifically set forth in the present description and which may be necessary for carrying out the present invention can be regarded as design matter for a person skilled in the art on the basis of known techniques in the technical field in question. The present invention can be carried out thus on the basis of the features disclosed in the present description and on the basis of common technical knowledge in the technical field in question.

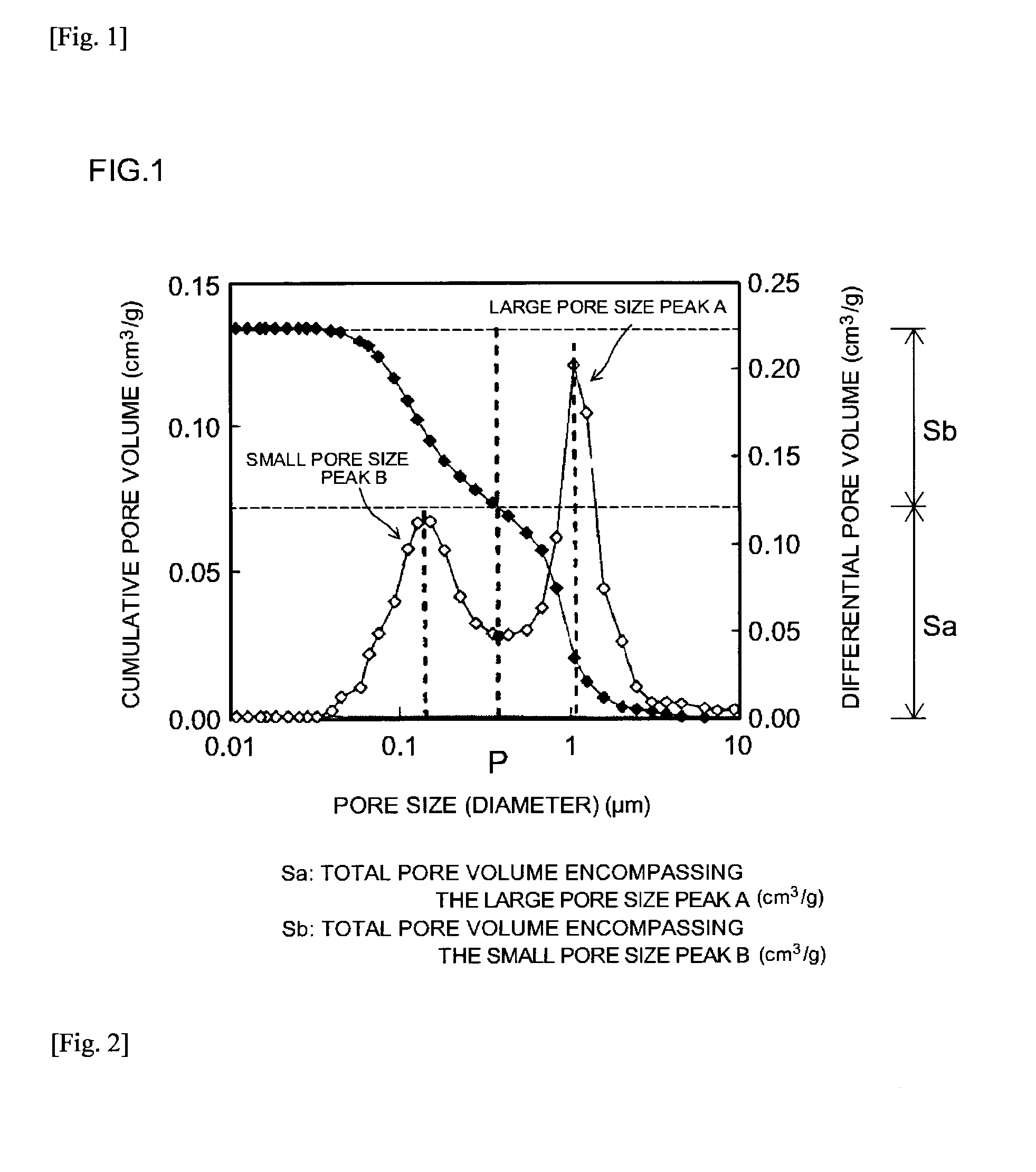

[0042]The various constituent elements of a positive electrode of the lithium secondary battery according to the present embodiment are explained first. As described above, the lithium secondary battery (typically, a lithium ion battery) disclosed herein comprises a positive electrode wherein a positive electrode mix layer that comprises a positive electrode active material and a conductive material are formed on the surface of a positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com