Die-Sized Atomic Magnetometer and Method of Forming the Magnetometer

a magnetometer and atomic magnetometer technology, applied in the field of atomic magnetometers, can solve the problems of limiting the types of applications where atomic magnetometers can be commercially utilized, and the ability of electrons to no longer absorb light energy,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

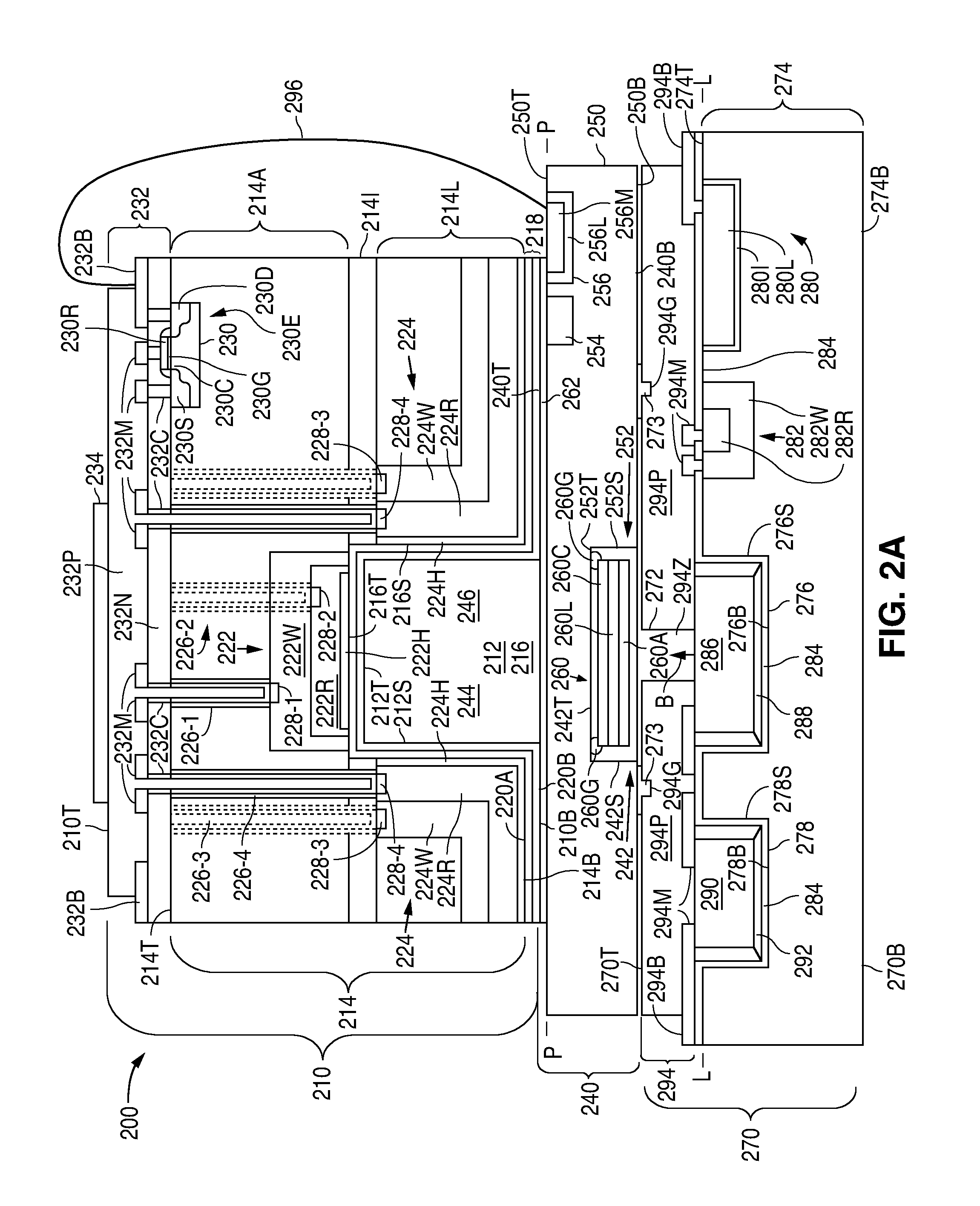

[0026]FIG. 2A shows a cross-sectional view that illustrates an example of a die-sized atomic magnetometer 200 in accordance with the present invention. As shown in FIG. 2A, atomic magnetometer 200 includes a first die 210 that has a top surface 210T, a bottom surface 2106, and a first die cavity 212 that extends into first die 210 from the bottom surface 210B of first die 210. First die cavity 212, in turn, has a top surface 212T and a side wall surface 212S. The top surface 212T of first die cavity 212 lies below and spaced apart from the top surface 210T of first die 210.

[0027]As further shown in FIG. 2A, first die 210 includes a first semiconductor structure 214 that has a top surface 214T, a bottom surface 214B, and a first semiconductor cavity 216 that extends into first semiconductor structure 214 from the bottom surface 214B of first semiconductor structure 214. First semiconductor cavity 216, in turn, has a top surface 216T and a side wall surface 216S. The top surface 216T ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com