High Performance Organic, Inorganic Or Hybrid Seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

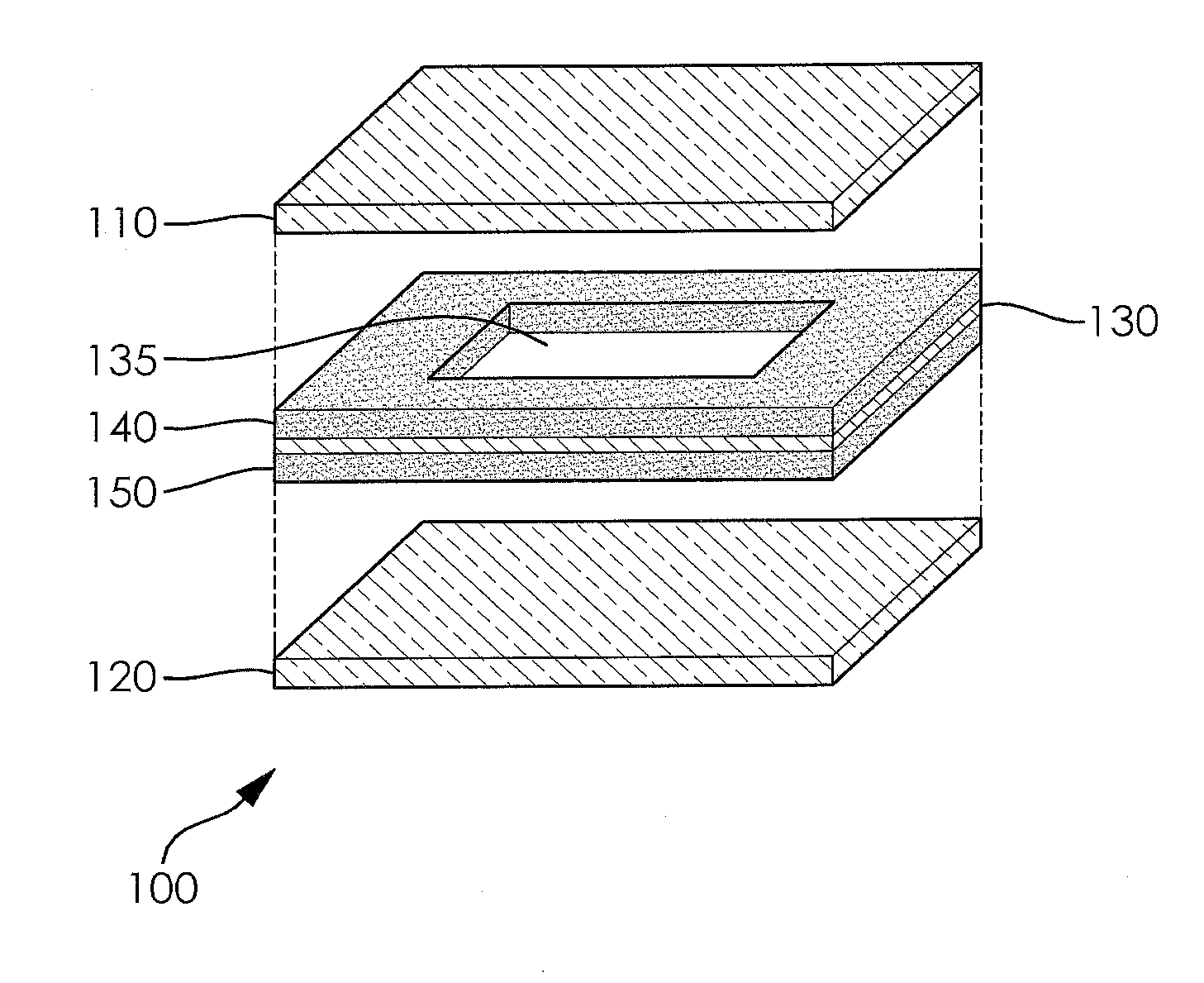

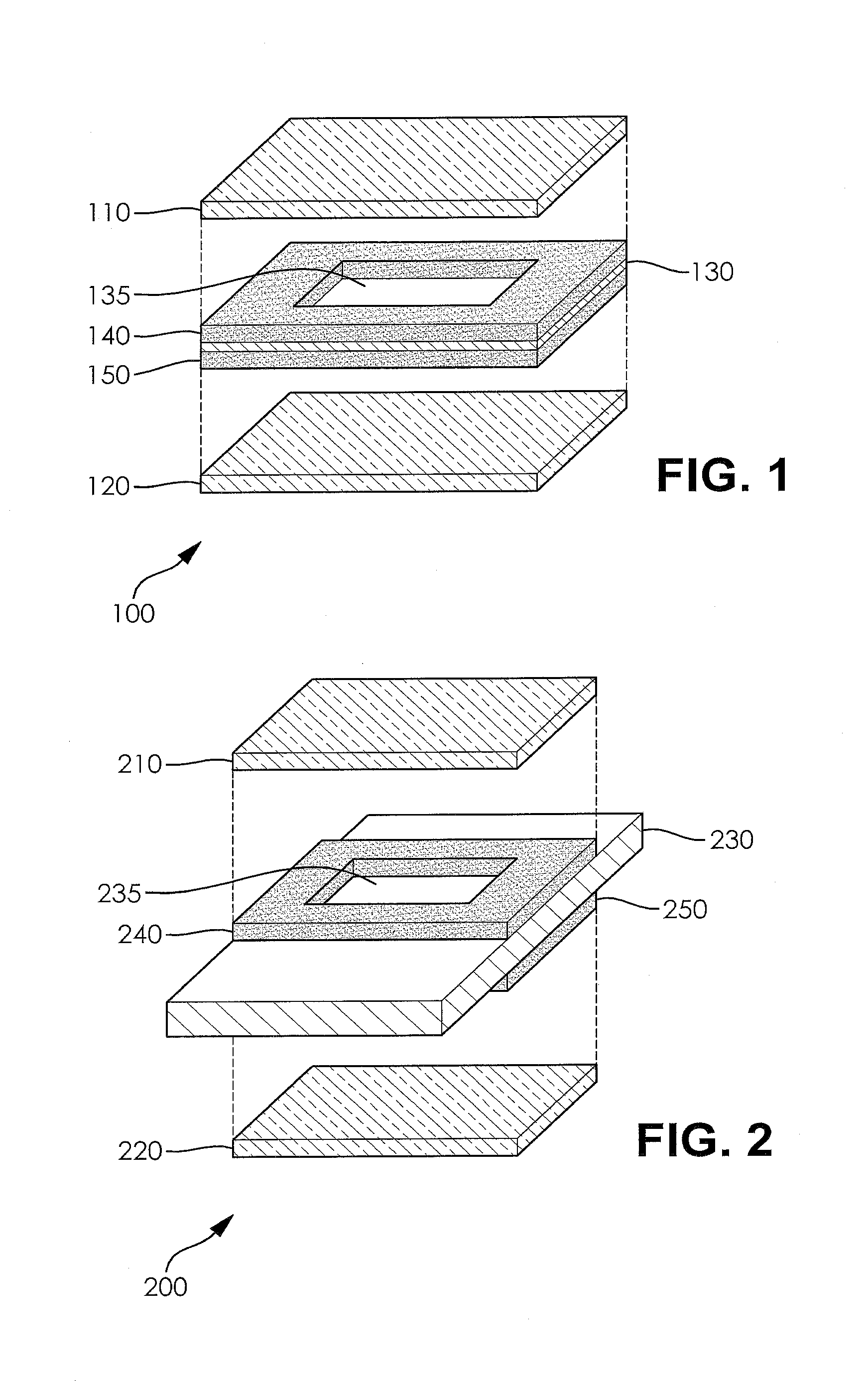

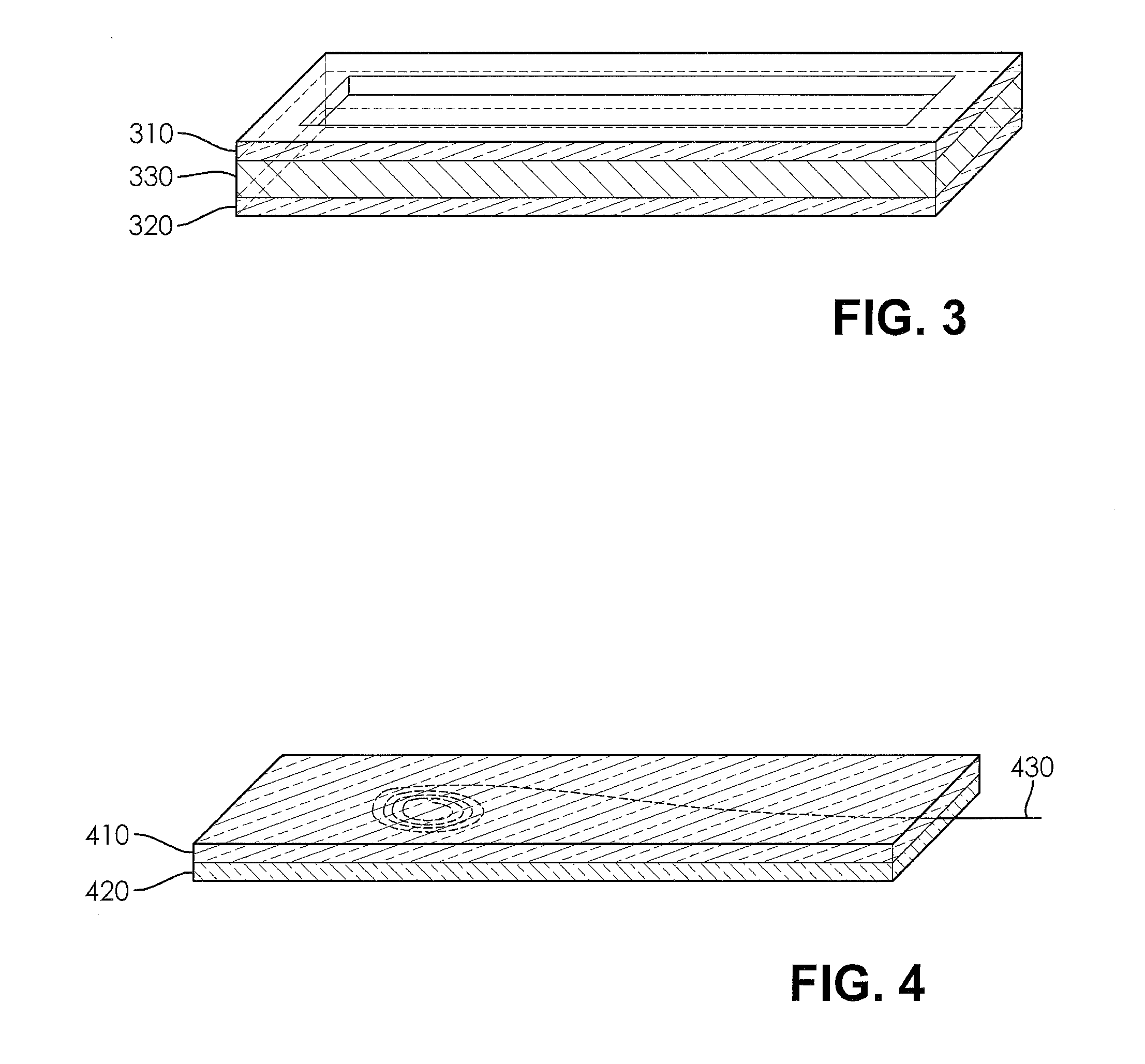

[0016]The present invention provides materials, seal designs, geometries and process steps for making hermetic seals, and simplifying the manufacture of hermetic seals which are used to protect active layers of electronic devices such as solar cells, LEDs, OLEDs, plasma display panels and the like.

[0017]A variety of substrates including those made of glass, metal, ceramic, or plastics, as well as those constituting active devices may be sealed together by this invention to create a hermetic seal in devices such as display devices (flat panel screens, LED screens, LCD screens, plasma display panels), organic light emitting diodes (OLEDs), solar cells and solar cell panels, and even windows for both architectural and automotive applications. The substrates may be coated with a coating such as conductive coated glass, indium tin oxide, aluminum doped zinc oxide, sputtered metals, antireflective coatings, SiNX coatings, Si3N4 coatings, conductive polymer coatings on glass, and combinati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com