Heat treatment method of unleaded brass alloy

a technology of unleaded brass and treatment method, which is applied in the field of unleaded brass alloy heat treatment method, can solve the problems of poor mechanical processability, affecting the human body and environment, and affecting the human body and environment, and achieves excellent mechanical processability, improved processability, and anti-corrosion property and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Exemplary embodiments now will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments are shown.

[0024]As used herein, the term ‘unleaded brass alloy’ means brass alloy containing no lead or containing a very small amount of lead.

[0025]In the following embodiments, naval brass may be used as an unleaded brass alloy material.

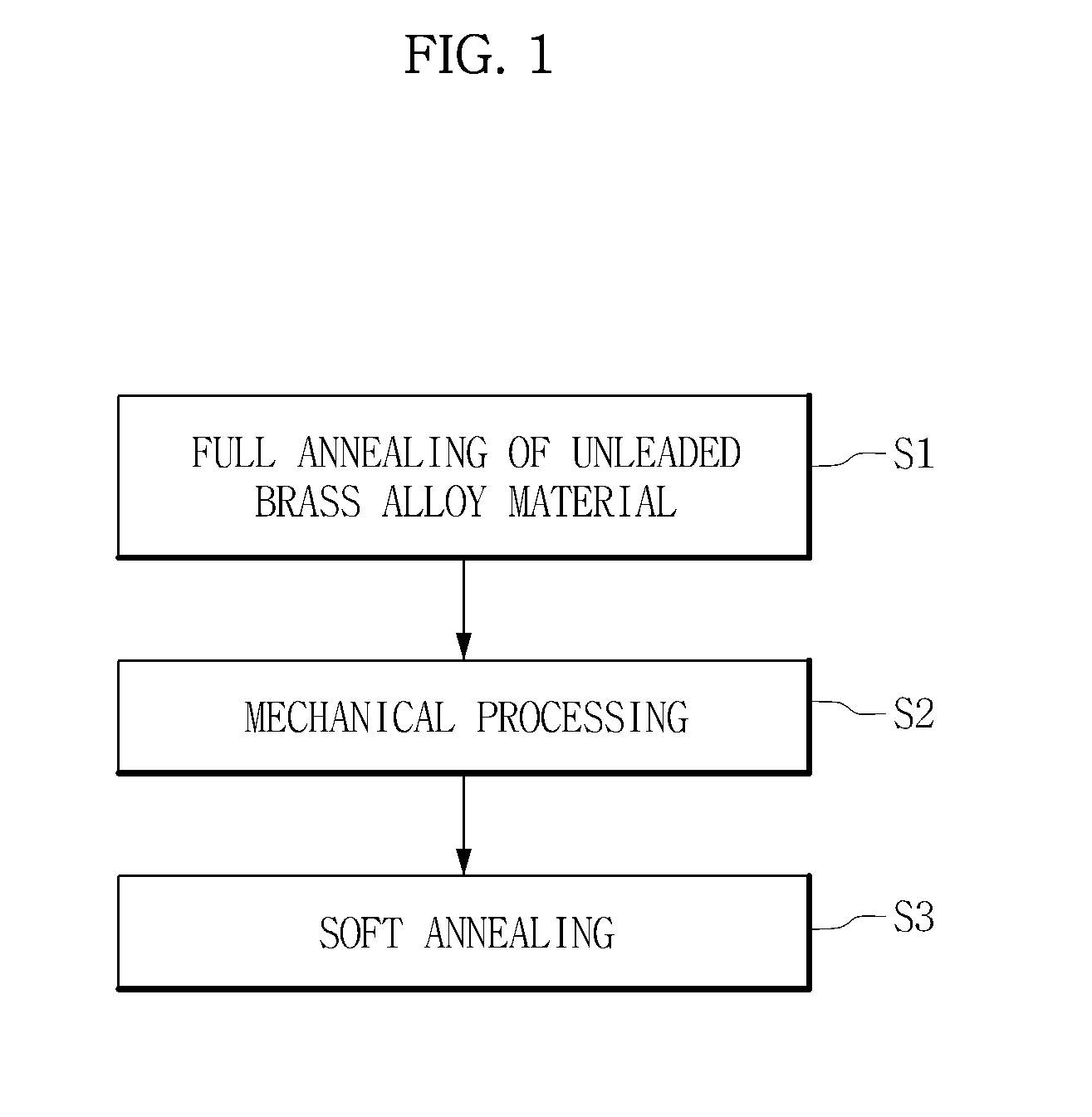

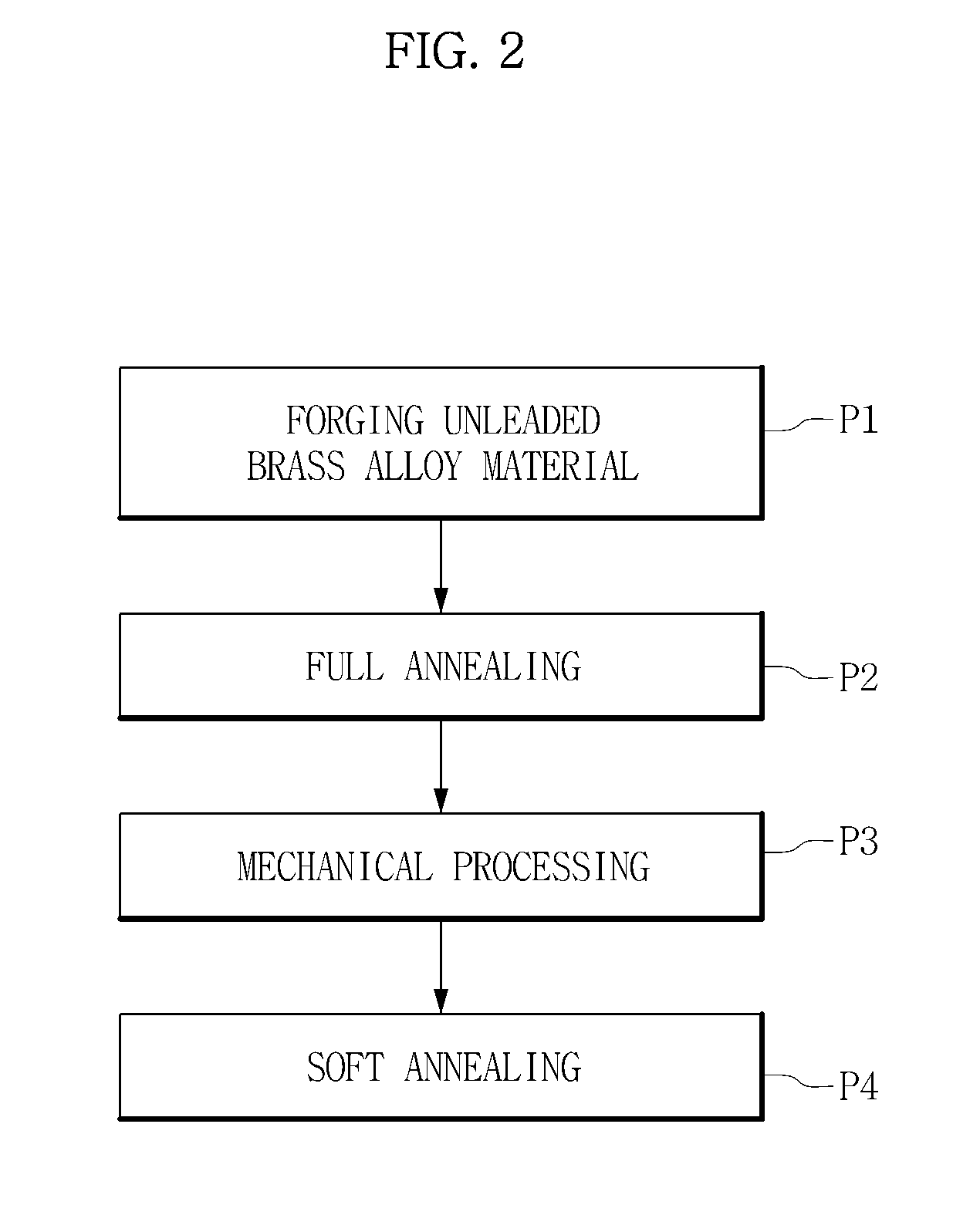

[0026]FIG. 1 is a diagram illustrating the heat treatment method according to an embodiment. As shown in FIG. 1, the heat treatment method includes an operation S1 of full annealing an unleaded brass alloy material, an operation S2 of mechanical processing the material after the operation S1, and an operation S3 of soft annealing the material after the operation S2.

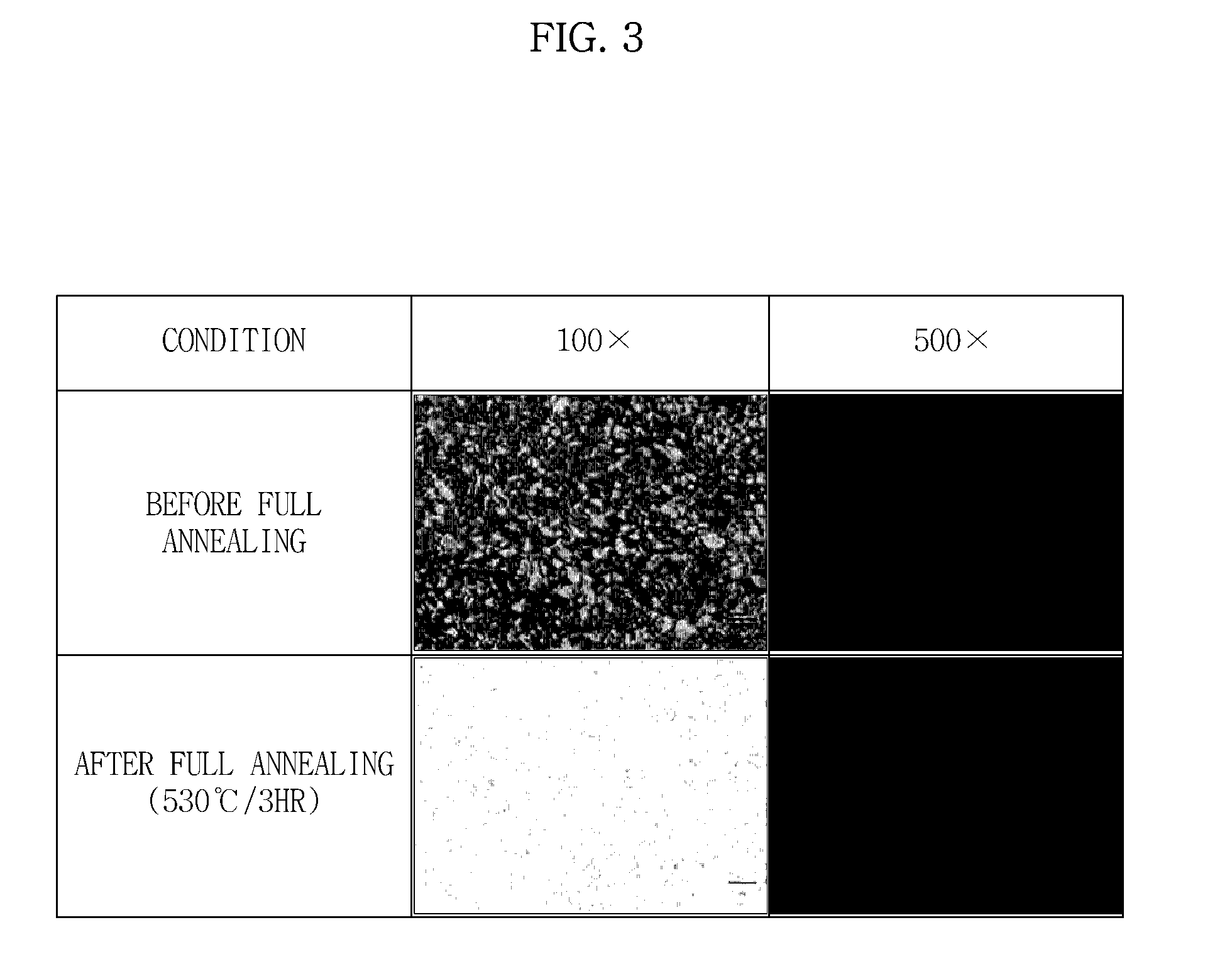

[0027]In the operation S1, the material is subjected to full annealing at a temperature of 530±30° C. for 3 hours. Such full annealing improves the mechanical processability of the material and removes boundary cracking caused by stress conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com