A kind of edge functionalized graphene, its preparation method and the purposes for preparing anticorrosion coating

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, chemical instruments and methods, epoxy resin coatings, etc., can solve problems such as restricting the application of graphene, irreparable, etc., to achieve excellent anti-corrosion characteristics, complete lamellar structure, Handleable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Add 300 mg of graphene prepared by turbulent flow method to 200ml H 2 SO 4 (98%), 1.8g NaClO 3 And 1mlH 2 O 2 (30%) in a mixed system, stirring at room temperature (25°C) for 8 hours, and then repeating centrifugal washing of the product to obtain edge-functionalized graphene with carboxyl groups selectively modifying the edges of the sheet.

[0052] (2) Weigh 2.5mg of edge-functionalized graphene, 300mg of phenolic resin, 40mg of gypsum powder filler, 20mg of polyacrylic acid additives and 30mg of p-toluenesulfonic acid curing agent, dispersed in 100ml of water, and mechanically stirred for 5 hours to obtain edge-functionalized graphene Composite anticorrosive coating.

[0053] The coating is applied to the surface of the substrate by spraying, and after drying, the edge-functionalized graphene composite anticorrosive coating is obtained.

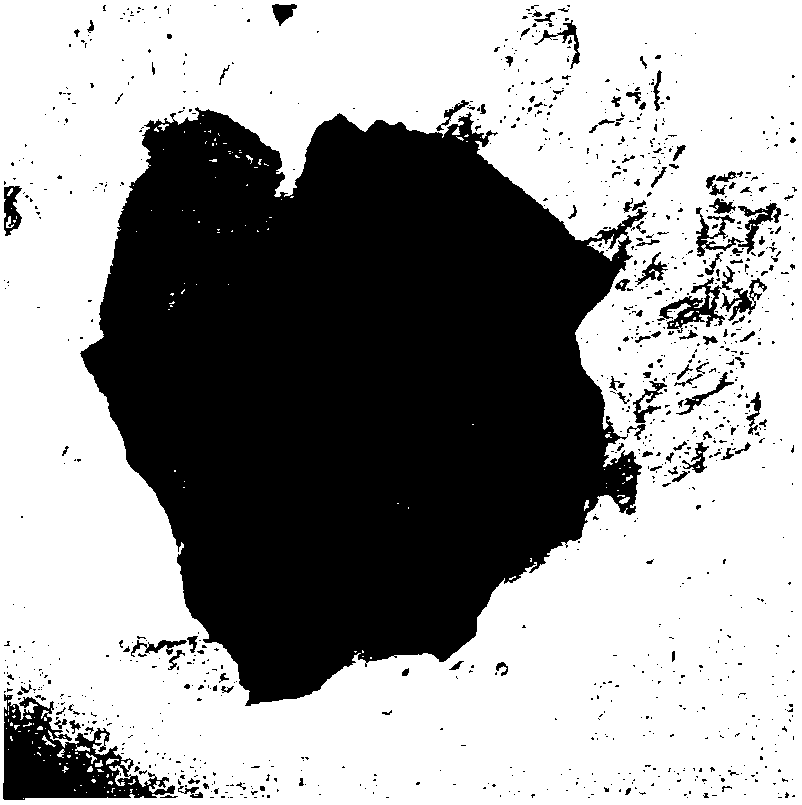

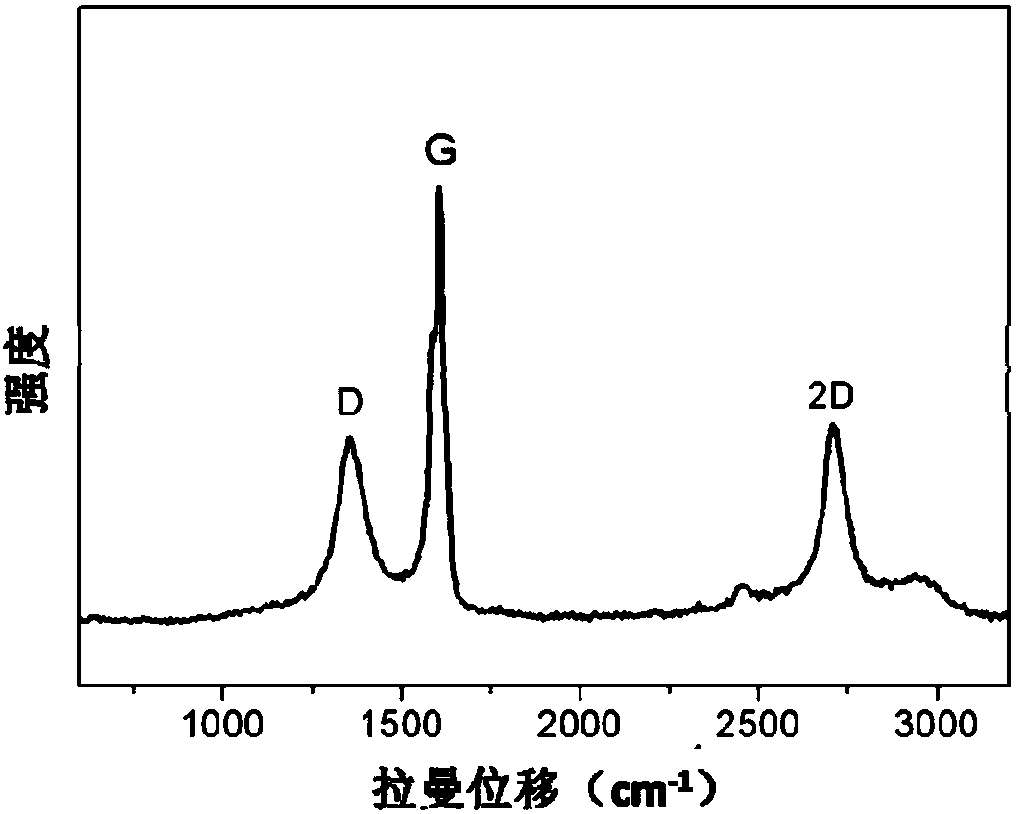

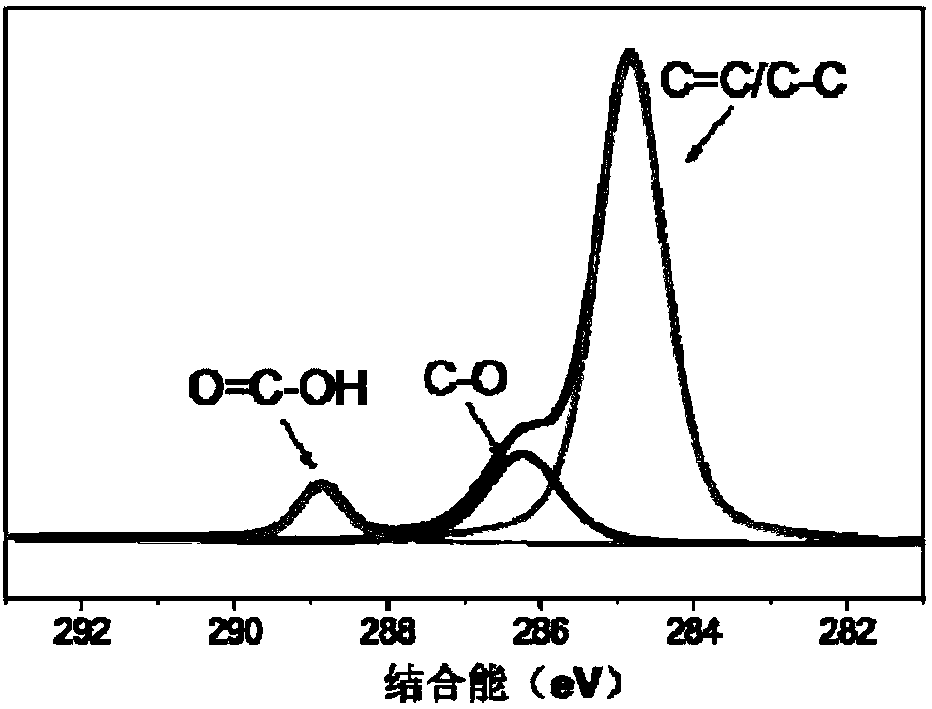

[0054] figure 1 with figure 2 TEM pictures and carbon Raman spectra of edge-functionalized graphene, showing its structural integrit...

Embodiment 2

[0058] (1) Add 1000 mg of graphene prepared by turbulent flow method to 200ml H 2 SO 4 (98%), 1.8g NaClO 3 And 0.04ml H 2 O 2 (30%) in a mixed system, stirred at 15°C for 4h, and then the product was repeatedly centrifuged and washed with water to obtain edge-functionalized graphene with carboxyl groups selectively modified at the edge of the sheet.

[0059] (2) Weigh 5mg edge-functionalized graphene, 60mg epoxy resin, 8mg talc filler, 10mg tributyl phosphate additive and 5mg m-phenylenediamine curing agent and disperse it in 80ml N-methylpyrrolidone. After 5h mechanical Stir to obtain edge functionalized graphene composite anticorrosive coating.

[0060] The coating is applied to the surface of the substrate by spraying, and after drying, the edge-functionalized graphene composite anticorrosive coating is obtained.

[0061] Table 1 shows that the edge-functionalized graphene anticorrosive coating of this embodiment has excellent corrosion resistance.

Embodiment 3

[0063] (1) Add 200 mg of graphene prepared by mechanical exfoliation to 10 ml of H 2 SO 4 (98%), 2g KClO 3 And 0.01ml H 2 O 2 (30%) in a mixed system, stirred at 0°C for 10 hours, and then the product was repeatedly centrifuged and washed with water to obtain edge-functionalized graphene with carboxyl groups selectively modified at the edge of the sheet.

[0064] (2) Weigh 70 mg of edge-functionalized graphene and disperse it in 30 ml of water, and stir it evenly for 1 hour to obtain edge-functionalized graphene one-component anticorrosive coating.

[0065] It is applied to the surface of the substrate by brushing, and after drying, the edge-functionalized graphene single-component anticorrosive coating is obtained.

[0066] Table 1 shows that the edge-functionalized graphene anticorrosive coating of this embodiment has excellent corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com