Epoxy resin composition for sealing, and electronic component device

a technology of epoxy resin and electronic components, applied in semiconductor devices, solid-state devices, semiconductor/solid-state device details, etc., can solve the problems of decreased moldability, increased complexity of wire bonding steps, and increased oxidation of copper surfaces, so as to improve mold release and continuous moldability during molding, the effect of superior adhesion to the copper lead fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

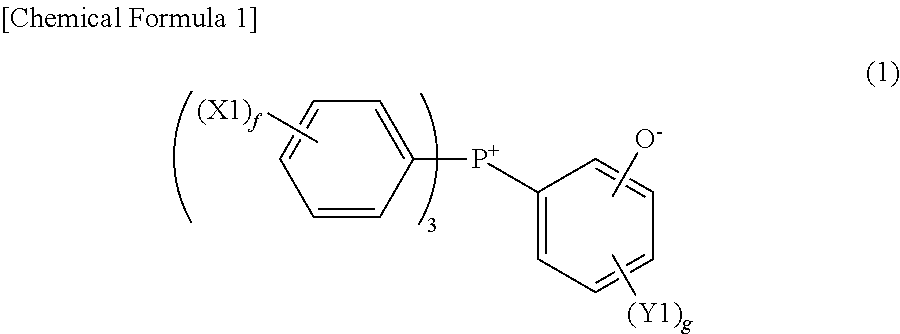

Method used

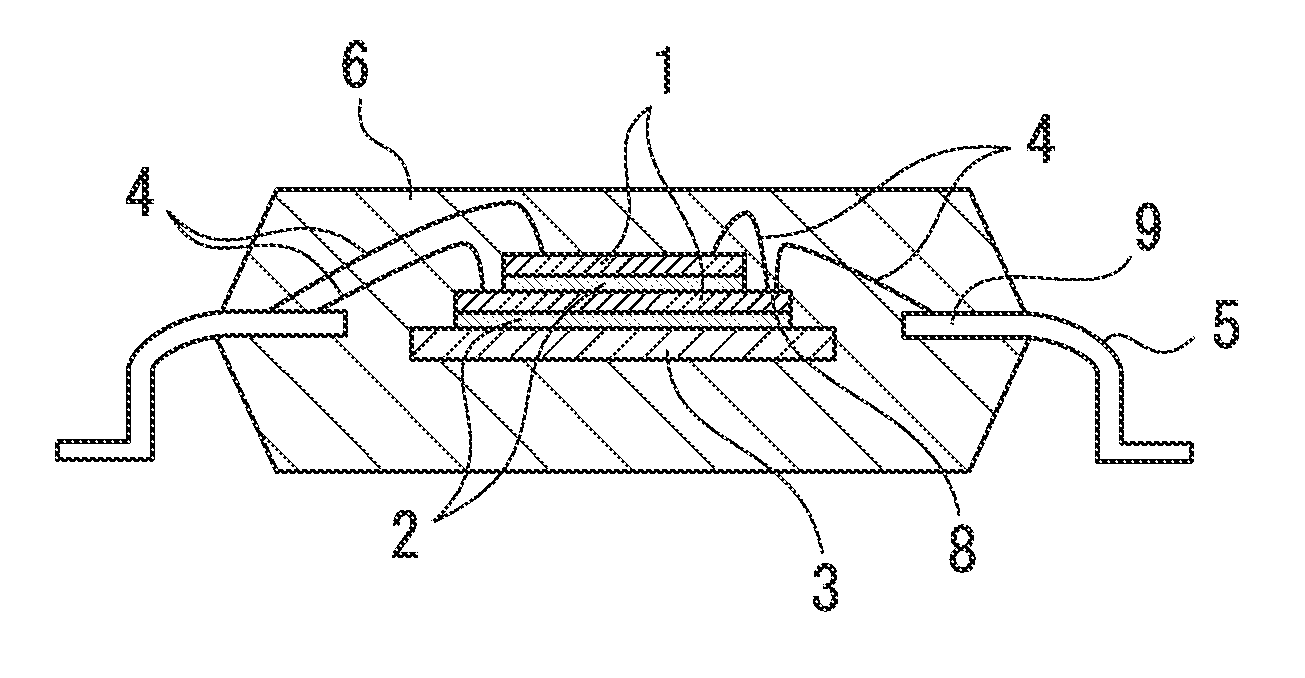

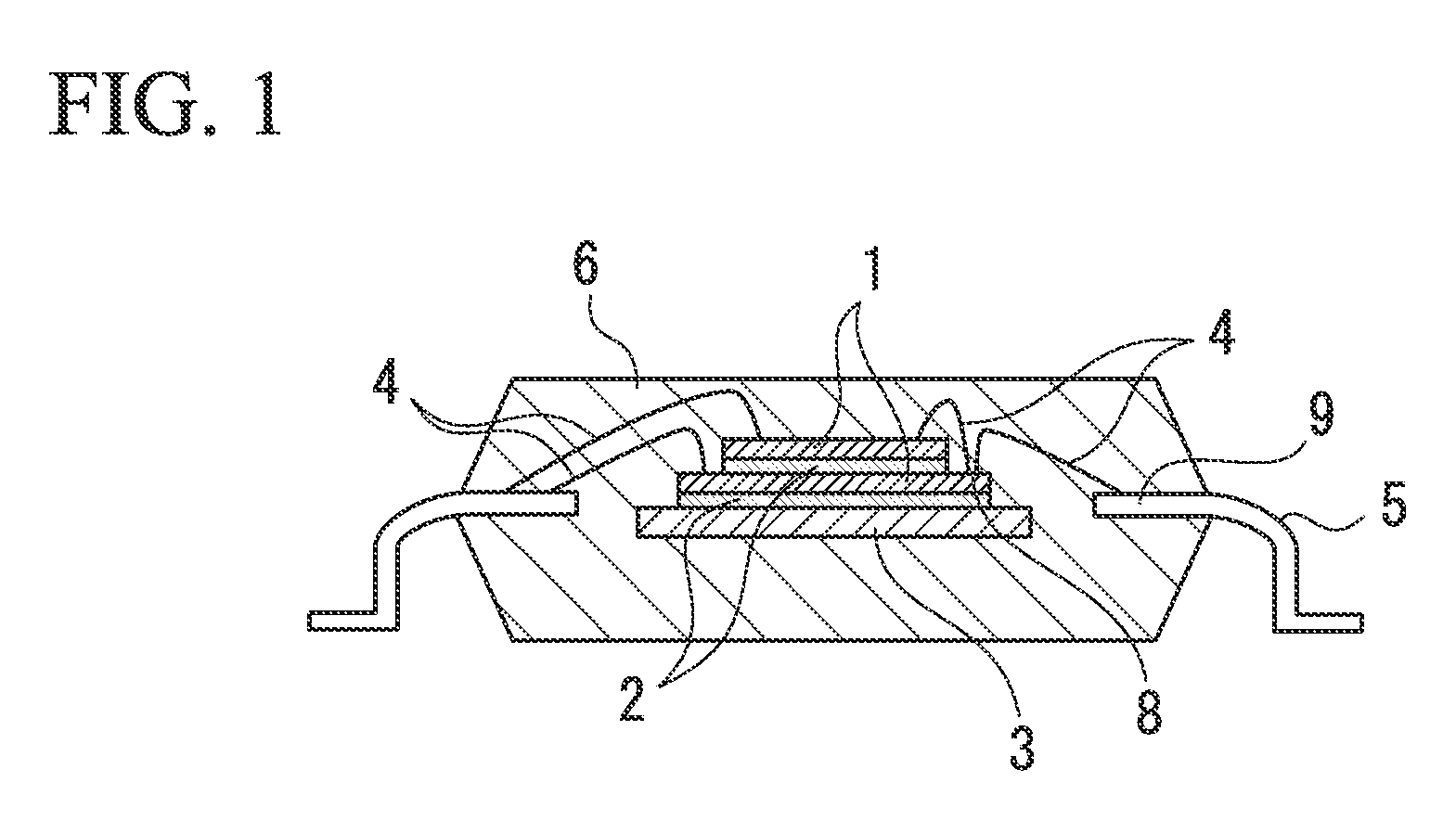

Image

Examples

example 1

[0070]44 parts by weight of epoxy resin (A-1):YX-4000, Mitsubishi Chemical Corp. (epoxy equivalent: 190 g / eq, melting point: 105° C.), 38 parts by weight of phenolic resin (B-1): XL-225, Mitsui Chemicals, Inc. (hydroxyl equivalent: 165 g / eq, softening point: 75° C.), 900 parts by weight of molten spherical silica (average particle diameter: 24 μm), 5 parts by weight of curing accelerator (D-1A), 5 parts by weight of silane coupling agent: γ-glycidoxypropyltrimethoxysilane (KBM-403, Shin-Etsu Chemical Co., Ltd.), 3 parts by weight of carbon black (#5, Mitsubishi Chemical Corp.) and 5 parts by weight of carnauba wax (Nikko Carnauba, Nikko Fine Co., Ltd.) were mixed with a mixer followed by kneading for 8 minutes at 95° C. using a heated roller, cooling and crushing to obtain an epoxy resin composition. The resulting epoxy resin composition was evaluated according to the methods described below. The results are shown in Table 1.

[0071]Evaluation Methods

[0072]Spiral flow: The epoxy resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com